Jet flow supporting and testing device for turning long and thin rods

A technology of experimental device and jet device, which is applied in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problems of inability to obtain geometric shape accuracy, surface quality, bending deformation and vibration, and affect processing accuracy. Achieve the effect of simple structure composition and design, reduce deformation and suppress vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

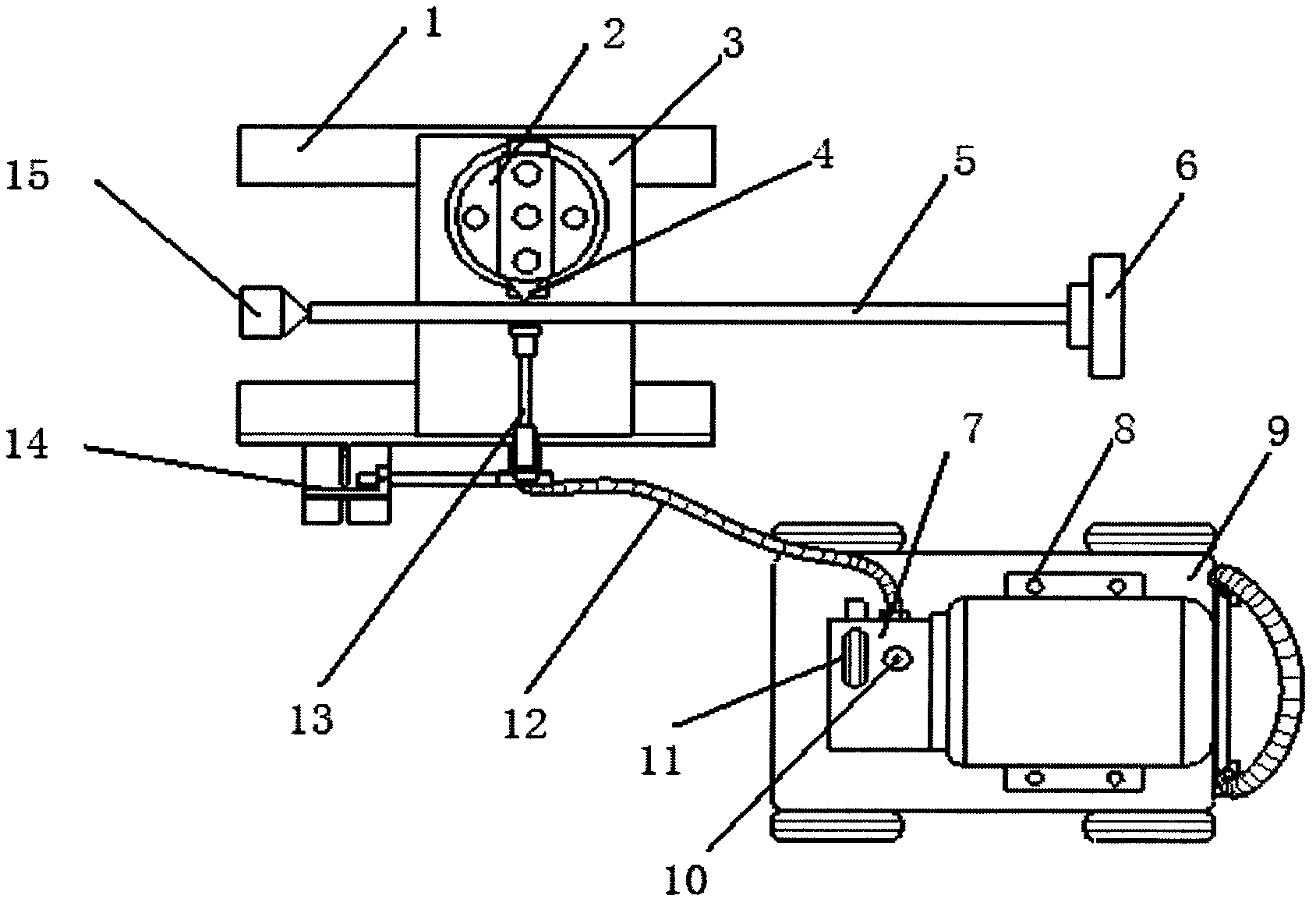

[0016] according to figure 1 , The jet support experimental device for slender rod turning is mainly composed of a jet device, a cutting force measurement device and a fixture device. The jet device includes a high-pressure pump 7, a motor 8, a trolley 9, an outlet pipe 12, a spray gun 13, and the like. The medium water (or coolant) is filtered from the tap (or water tank) and enters the high-pressure pump 7 from the water inlet pipe. After being pressurized by the high-pressure pump 7, it is sprayed out through the water outlet pipe 12 and the nozzle of the spray gun 12. The impact force generated by the jet It acts on the slender rod workpiece, provides auxiliary support for turning processing, and can offset part of the cutting force to reduce workpiece deformation. The high-pressure pump 7 is equipped with a pressure regulating valve 10 and a digital display pressure gauge 11. The pressure regulating valve 10 is used to adjust the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com