A method for manufacturing decorative concrete light-weight wall panels

A technology for decorative concrete and production method, which is applied in the direction of pressing rollers, etc., can solve the problems of glass fiber reinforced cement wallboard without stone texture, large volume, and increased building load, etc., to reduce volume and weight, small volume, and reduce thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

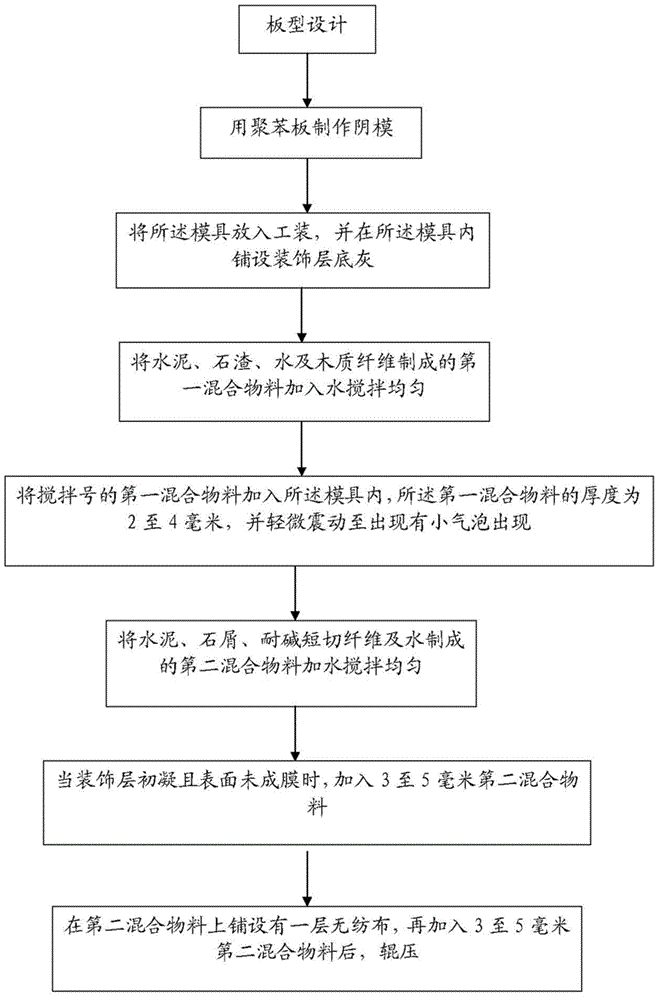

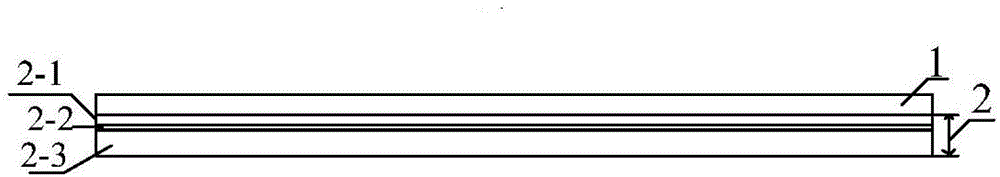

[0042] like figure 1 As shown in the figure, a method for making decorative concrete light-weight wall panels of the present invention includes panel design, production of polystyrene panels to make negative molds, organization of tooling, production of decorative layers and structural layers, demoulding and maintenance, wherein the decorative layers The production process includes the following steps:

[0043] Step (1), put the mold into the tooling, fix the mold and the tooling by means of a clamp, and lay a layer of bottom ash in the mold; this step can ensure that the decoration layer is easy to disassemble and ensure the decoration layer. The surface is easy to sand.

[0044] Step (2), the cement, gravel and water wood fiber are mixed and stirred uniformly according to the mass percentage ratio of 1:2:0.38:0.05 to prepare the first mixed material, and the particle size of the gravel is 0.5-0.8 mm;

[0045] Step (3), add the stirred first mixed material into the mold, th...

Embodiment 2

[0055] like figure 1 As shown in the figure, the present invention is a method for making decorative concrete light-weight wall panels, including plate design, mold making, organization tooling, making of decorative layer and structural layer, demoulding and maintenance, wherein the production process of the decorative layer includes the following step:

[0056] Step (1), put the mold into the tooling, fix the mold and the tooling by means of a clamp, and lay a layer of bottom ash in the mold; this step can ensure that the decoration layer is easy to disassemble and ensure the decoration layer. The surface is easy to sand.

[0057] In step (2), the cement, gravel and water wood fiber are mixed and stirred uniformly according to the mass percentage ratio of 1:1:0.38:0.05 to prepare a first mixed material, and the particle size of the gravel is 0.5-1 mm.

[0058] Step (3), adding the stirred first mixed material into the mold, the thickness of the first mixed material is 3 mm,...

Embodiment 3

[0068] like figure 1 As shown in the figure, the present invention is a method for making decorative concrete light-weight wall panels, including plate design, mold making, organization tooling, making of decorative layer and structural layer, demoulding and maintenance, wherein the production process of the decorative layer includes the following step:

[0069] Step (1), put the mold into the tooling, fix the mold and the tooling by means of a clamp, and lay a layer of bottom ash in the mold; this step can ensure that the decoration layer is easy to disassemble and ensure the decoration layer. The surface is easy to sand.

[0070] In step (2), the cement, gravel and water wood fiber are mixed and stirred uniformly according to the mass percentage ratio of 1:3:0.05:0.5 to prepare the first mixed material, and the particle size of the gravel is 0.6-1.2 mm.

[0071] Step (3), adding the stirred first mixed material into the mold, the thickness of the first mixed material is 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com