Improved metal printed composite household board

A printing and metal technology, which is applied in the field of improved metal printing composite home panels, can solve the problems of home panel installation performance, poor adhesion, etc., and achieve the effects of improved adhesion, strong solubility, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

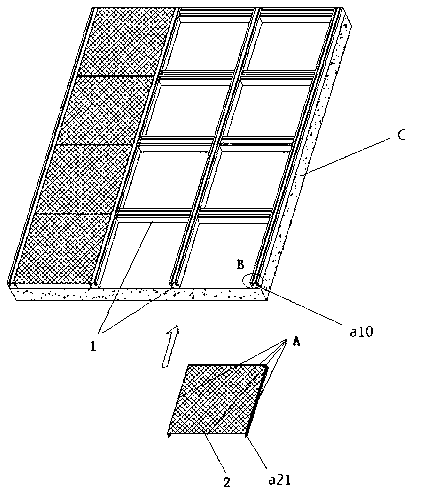

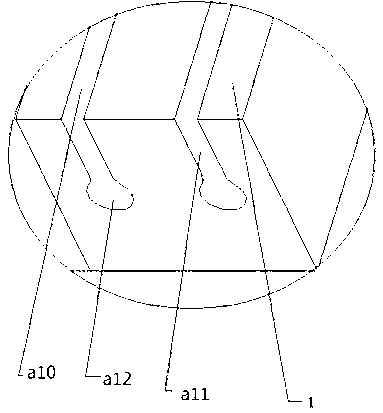

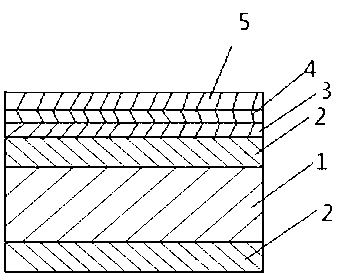

[0055] like figure 1 and figure 2 As shown, this embodiment provides a metal-printed composite home panel, which includes several keels 1 and several metal-printed panels 2, and several keels 1 are arranged vertically and horizontally at intervals to form several installation frames surrounded by three sides and one side is open, and several metal-printed panels 2 sequentially closely and flatly installed on the installation frame formed by the keels 1; wherein, each of the keels 1 is provided with a plastic insertion groove a10, and the diameter of the opening of the plastic insertion groove a10 gradually decreases from outside to inside along the thickness direction of the keel 1; the plastic insertion groove a10 has an insertion gap a11 close to the opening and a locking portion a12 communicating with the insertion gap a11; the metal stamping The panel 2 has an insertion portion a21, and the insertion portion a21 is inserted into the plastic insertion groove a10 from the ...

Embodiment 2

[0079] like figure 1 and figure 2 As shown, this embodiment provides a metal-printed composite home panel, which includes several keels 1 and several metal-printed panels 2, and several keels 1 are arranged vertically and horizontally at intervals to form several installation frames surrounded by three sides and one side is open, and several metal-printed panels 2 sequentially closely and flatly installed on the installation frame formed by the keels 1; wherein, each of the keels 1 is provided with a plastic insertion groove a10, and the diameter of the opening of the plastic insertion groove a10 gradually decreases from outside to inside along the thickness direction of the keel 1; the plastic insertion groove a10 has an insertion gap a11 close to the opening and a locking portion a12 communicating with the insertion gap a11; the metal stamping The panel 2 has an insertion portion a21, and the insertion portion a21 is inserted into the plastic insertion groove a10 from the ...

Embodiment 3

[0105] like figure 1 and figure 2 As shown, this embodiment provides a metal-printed composite home panel, which includes several keels 1 and several metal-printed panels 2, and several keels 1 are arranged vertically and horizontally at intervals to form several installation frames surrounded by three sides and one side is open, and several metal-printed panels 2 sequentially closely and flatly installed on the installation frame formed by the keels 1; wherein, each of the keels 1 is provided with a plastic insertion groove a10, and the diameter of the opening of the plastic insertion groove a10 gradually decreases from outside to inside along the thickness direction of the keel 1; the plastic insertion groove a10 has an insertion gap a11 close to the opening and a locking portion a12 communicating with the insertion gap a11; the metal stamping The panel 2 has an insertion portion a21, and the insertion portion a21 is inserted into the plastic insertion groove a10 from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com