Liquid crystal display screen thinning pretreatment liquid and liquid crystal display screen thinning method

A liquid crystal display and pretreatment liquid technology, applied in the field of liquid crystal display thinning pretreatment liquid and liquid crystal display thinning, can solve the problem of increasing production costs, uneven thinning of glass substrates, and affecting the yield of liquid crystal displays and other problems, to achieve the effect of preventing crack enlargement, improving yield rate, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

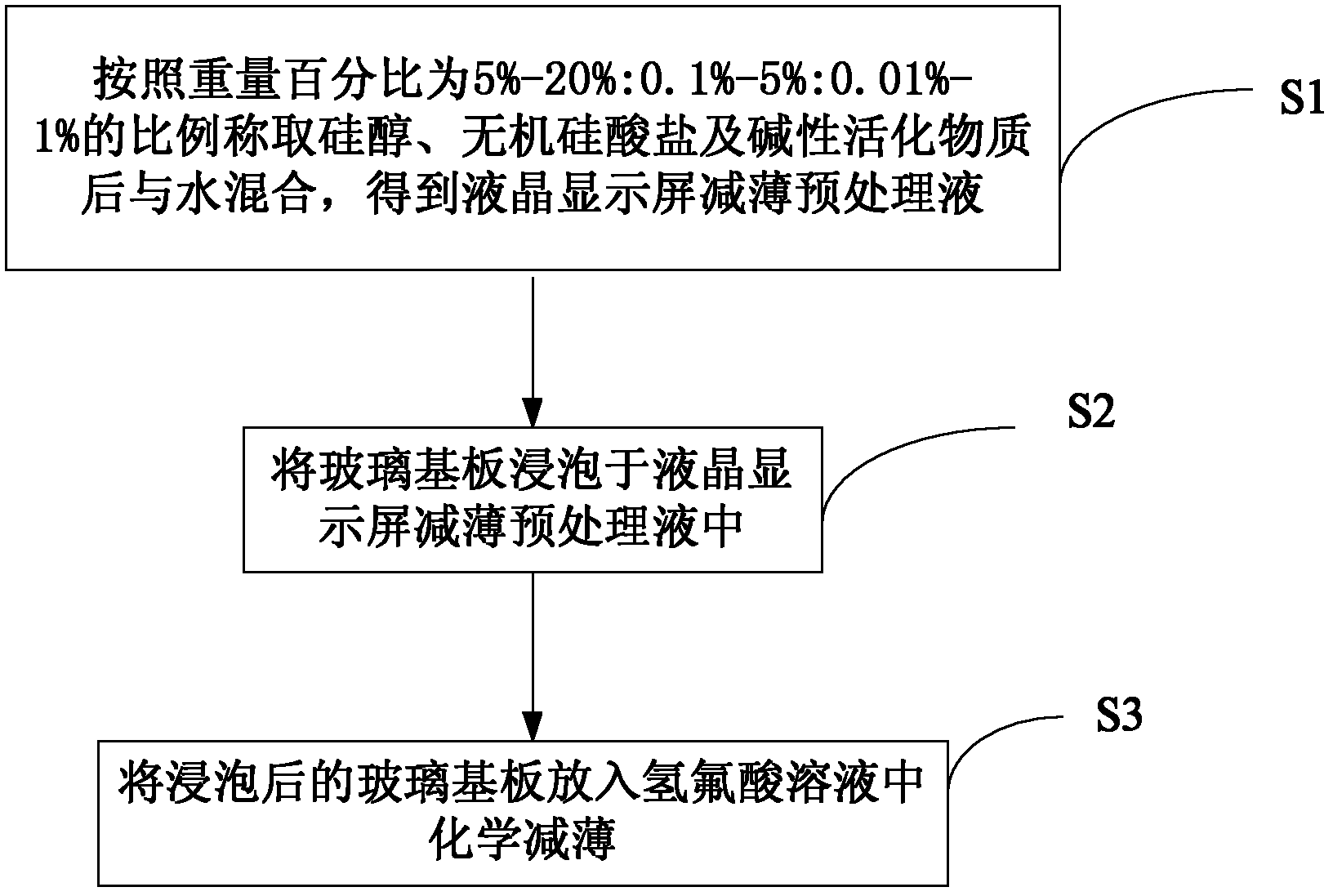

[0036] (1) Preparation of liquid crystal display thinning pretreatment liquid: take by weighing (CH 3 ) 3 SiOH, Na 2 SiO 3 and NaOH, mixed with water to prepare liquid crystal display thinning pretreatment liquid.

[0037] (2) Soak the TFT glass substrate in the liquid crystal display thinning pretreatment solution at a temperature of 30° C. for 2 hours, then clean the TFT glass substrate and dry it.

[0038] (3) Then put the TFT glass substrate into an etching tank containing 5% hydrofluoric acid solution of HF for chemical thinning, the temperature of chemical thinning is 40° C., and the time is 2 hours.

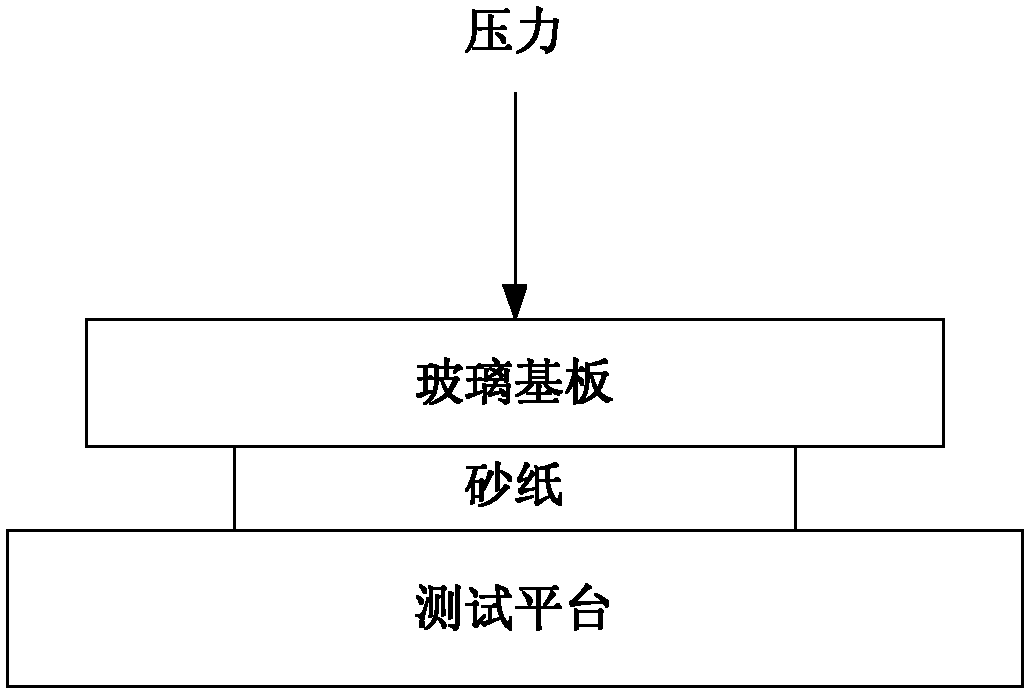

[0039] Such as figure 2As shown, the test method for the thinned TFT glass substrate is as follows: place sandpaper with a size of 10mm×10mm and a mesh number of 100 on a horizontal test bench, place the thinned TFT glass substrate on the sandpaper, and place it on the sandpaper. A pressure of 5Kg is applied on the TFT glass substrate, and the effect is characterized...

Embodiment 2

[0043] (1) Preparation of liquid crystal display thinning pretreatment liquid: take by weighing (CH 3 ) 2 Si(OH) 2 、K 2 SiO 3 and alkaline activators, mixed with water to prepare liquid crystal display thinning pretreatment solution, wherein the alkaline activators are NaOH and KOH.

[0044] (2) Soak the TFT glass substrate in the liquid crystal display thinning pretreatment solution at a temperature of 60° C. for 0.5 hour, then clean the TFT glass substrate and dry it.

[0045] (3) Then put the TFT glass substrate into an etching tank containing a hydrofluoric acid solution with a mass percentage of HF of 15% for chemical thinning. The chemical thinning temperature is 30° C. and the time is 2 hours.

[0046] Such as figure 2 As shown, the test method for the thinned TFT glass substrate is as follows: place sandpaper with a size of 10mm×10mm and a mesh number of 100 on a horizontal test bench, place the thinned TFT glass substrate on the sandpaper, and place it on the sa...

Embodiment 3

[0050] (1) Preparation of liquid crystal display thinning pretreatment liquid: take by weighing (CH 3 CH 2 ) 3 SiOH, K 2 SiO 3 and KOH and then mixed with water to prepare liquid crystal display thinning pretreatment liquid.

[0051] (2) Soak the TFT glass substrate in the liquid crystal display thinning pretreatment solution at a temperature of 40° C. for 1.5 hours, then clean the TFT glass substrate and dry it.

[0052] (3) Then put the TFT glass substrate into an etching tank containing a hydrofluoric acid solution with a mass percentage of HF of 20% for chemical thinning. The temperature of chemical thinning is 20° C. and the time is 3 hours.

[0053] Such as figure 2 As shown, the test method for the thinned TFT glass substrate is as follows: place sandpaper with a size of 10mm×10mm and a mesh number of 100 on a horizontal test bench, place the thinned TFT glass substrate on the sandpaper, and place it on the sandpaper. A pressure of 5Kg is applied on the TFT glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com