Waterborne polyurethane weather-proof elastic waterproof paint

A water-based polyurethane and waterproof coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of cumbersome coating process, poor anti-ultraviolet radiation, poor crack resistance, etc., achieve high construction efficiency, counterbalance the microscopic wall The effect of cracking and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

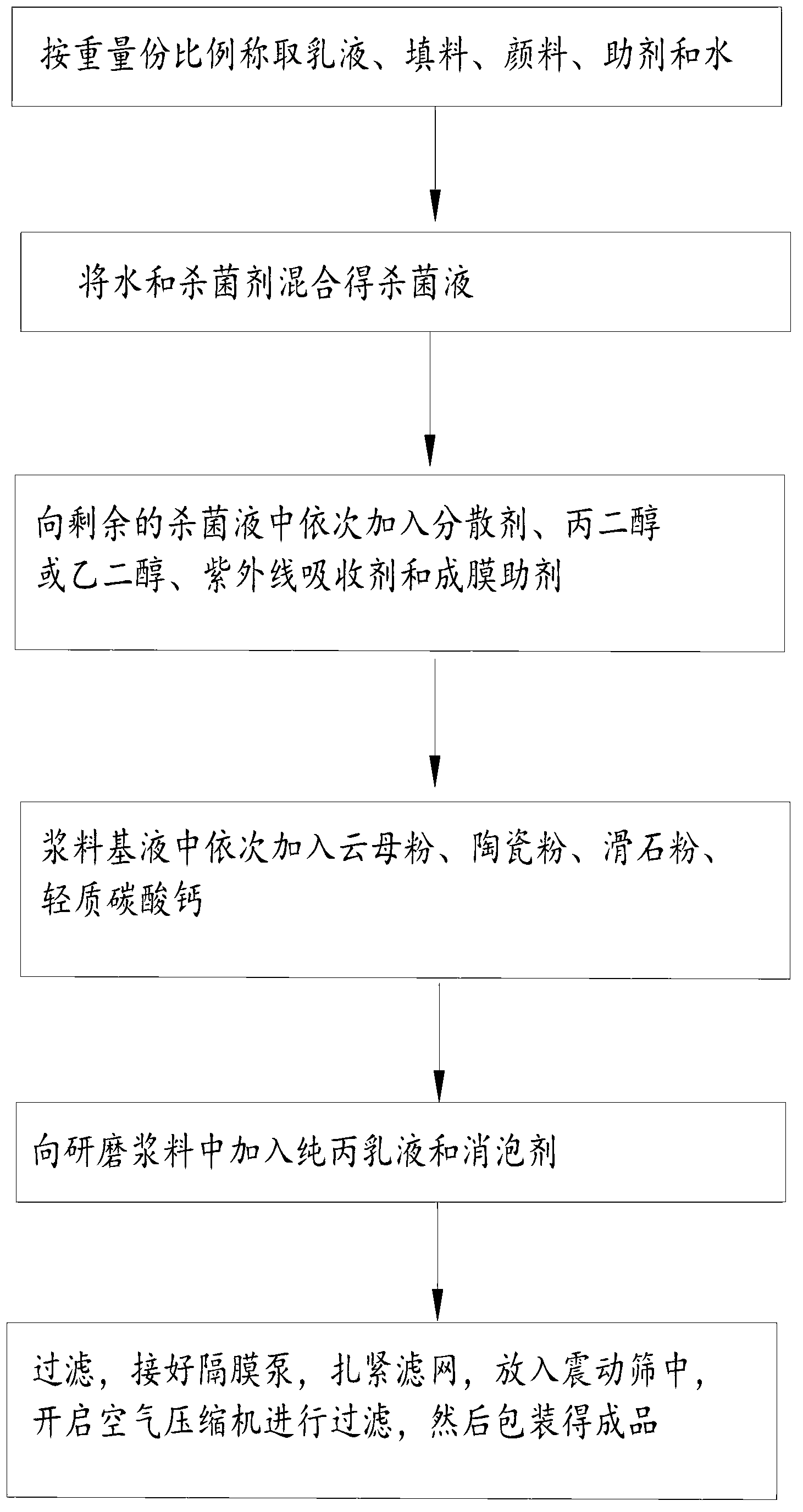

Method used

Image

Examples

Embodiment 1

[0143] Waterborne polyurethane weather-resistant elastic waterproof coating, including emulsion, filler, pigment, additive and water;

[0144] The emulsion contains the following components by weight:

[0145] Elastic waterproof lotion 10 parts,

[0146] 30 parts of waterborne polyurethane prepolymer;

[0147] The filler comprises the following components by weight:

[0148] 5 parts of talcum powder,

[0149] Ceramic powder 5 parts,

[0150] 5 parts of light calcium carbonate;

[0151] The pigment is mica powder, preferably 800 order mica powder,

[0152] 15 parts of 800 mesh mica powder;

[0153] The auxiliary agent comprises the following components by weight:

[0154] 2 parts of propylene glycol,

[0155] 1 part of film-forming aid,

[0156] 0.5 part of fungicide,

[0157] Leveling agent 0.5 parts,

[0158] Dispersant 0.2 part,

[0159] Thickener 0.5 parts,

[0160] 0.1 part of defoamer,

[0161] 0.15 part of ultraviolet absorber,

[0162] 0.2 parts of pH regul...

Embodiment 2

[0183] Waterborne polyurethane weather-resistant elastic waterproof coating, including emulsion, filler, pigment, additive and water;

[0184] The emulsion contains the following components by weight:

[0185] Elastic waterproof lotion 13 parts,

[0186] 33 parts of waterborne polyurethane prepolymer;

[0187] The filler comprises the following components by weight:

[0188] Talcum powder 10 parts,

[0189] Ceramic powder 10 parts,

[0190] 10 parts of light calcium carbonate;

[0191] The pigment is mica powder, preferably 800 order mica powder,

[0192] 18 parts of 800 mesh mica powder;

[0193] The auxiliary agent comprises the following components by weight:

[0194] 3 parts of propylene glycol,

[0195] 1 part of film-forming aid,

[0196] 0.6 part of fungicide,

[0197] Leveling agent 0.5 parts,

[0198] Dispersant 0.6 part,

[0199] Thickener 0.6 part,

[0200] 0.1 part of defoamer,

[0201] 0.2 part of ultraviolet absorber,

[0202] 0.2 parts of pH regul...

Embodiment 3

[0220] Waterborne polyurethane weather-resistant elastic waterproof coating, including emulsion, filler, pigment, additive and water;

[0221] The emulsion contains the following components by weight:

[0222] Elastic waterproof lotion 17 parts,

[0223] 37 parts of waterborne polyurethane prepolymer;

[0224] The filler comprises the following components by weight:

[0225] Talcum powder 12 parts,

[0226] Ceramic powder 15 parts,

[0227] 12 parts of light calcium carbonate;

[0228] The pigment is mica powder, preferably 800 order mica powder,

[0229] 25 parts of 800 mesh mica powder;

[0230] The auxiliary agent comprises the following components by weight:

[0231] 4 parts of ethylene glycol,

[0232] 2 parts of film-forming aids,

[0233] 0.8 part of fungicide,

[0234] Leveling agent 0.7 parts,

[0235] Dispersant 0.7 part,

[0236] Thickener 0.8 part,

[0237] 0.2 part of defoamer,

[0238] 0.4 part of ultraviolet absorber,

[0239] 0.4 parts of PH regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com