Tubular circulating bioreactor and tubular circulating biological reaction system device

A technology of bioreactor and bioreaction, which is applied in the direction of bioreactor/fermenter combination, biochemical cleaning device, specific-purpose bioreactor/fermenter, etc. Problems such as large consumption of steam and water, to achieve the effect of reducing energy consumption, complete sterilization, and reducing pipe resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

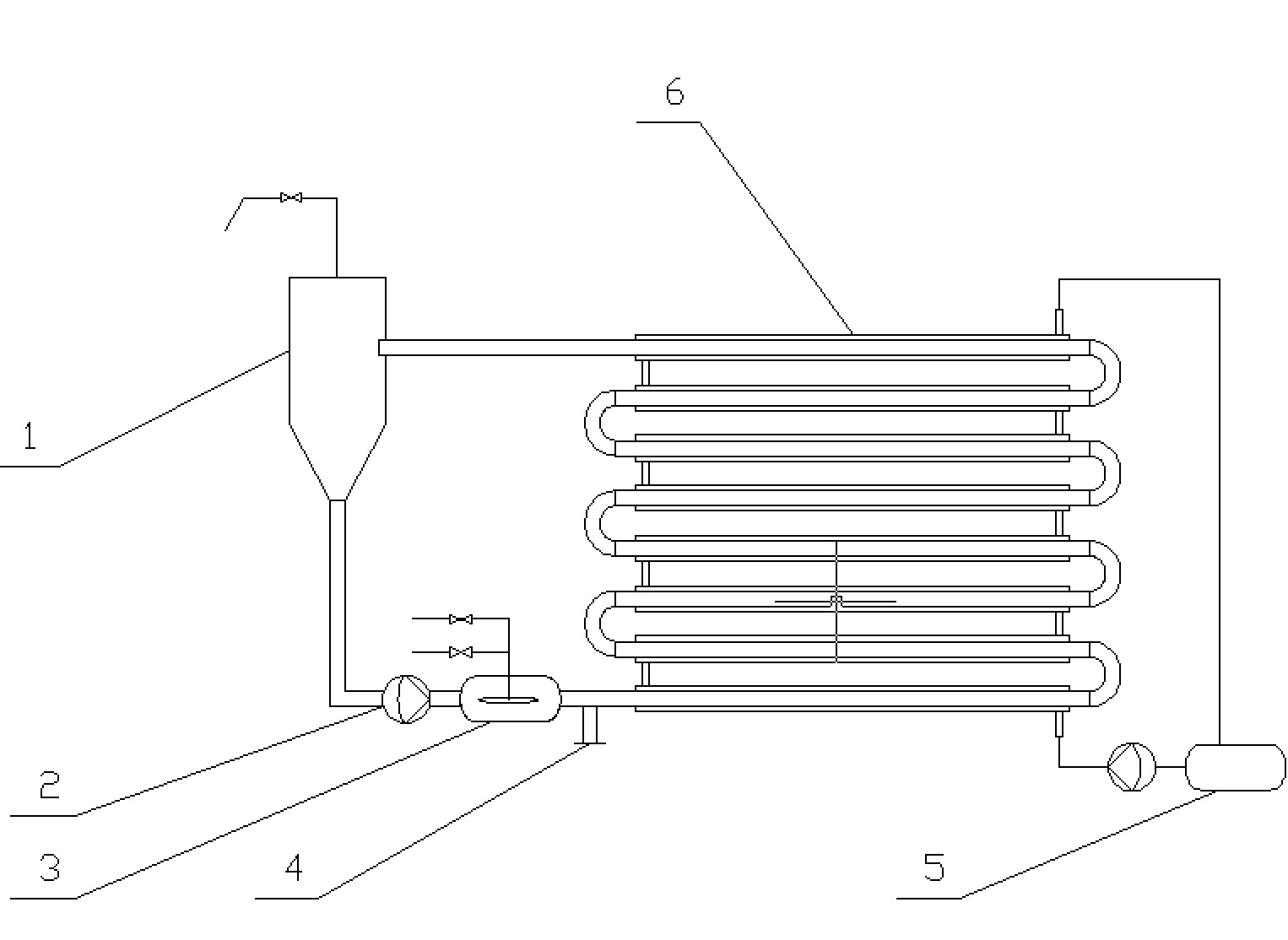

[0030] A tubular circulation bioreactor, which is composed of curved pipes with an up-and-down reciprocating circulation structure connected end to end. The two ends of the circulation pipe are connected by sanitary quick clips, and the pipes are connected by "U" elbows. , Detachable, arbitrary increase or decrease in length, the distance between the circulation pipes is 1 times the pipe diameter, the pipes are stainless steel seamless steel pipes, the inner wall is polished without dead ends, and the outer layer is interlayered.

[0031] A tubular circulation biological reaction system device, including a culture fluid gas-liquid separation device, a culture fluid circulation pump, a gas-liquid mixing device, a tubular circulation bioreactor, and a temperature-controlled purification device, wherein the culture fluid gas-liquid separation device, the culture fluid The circulating pump, the gas-liquid mixing device and the tubular circulation bioreactor are connected through pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com