Method and relevant device for achieving metal mutual connection through preparation of micro-protruding-points with superfine spaces

A metal interconnection and micro-bump technology, applied in the field of microelectronics, can solve problems such as undercutting and pitch reduction, and achieve the effects of reduced flatness, reduced requirements, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

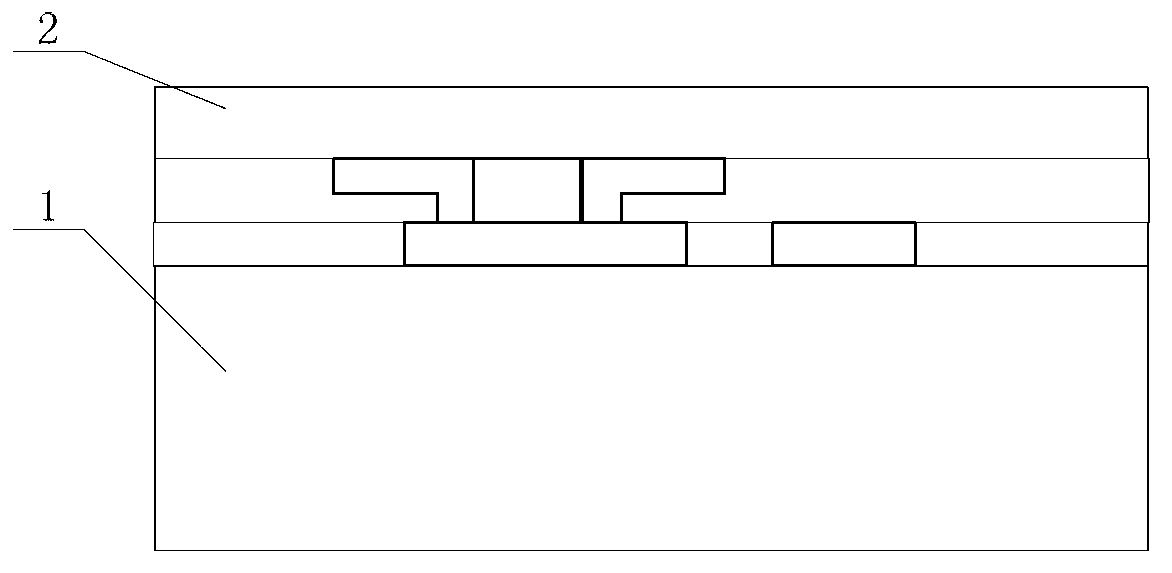

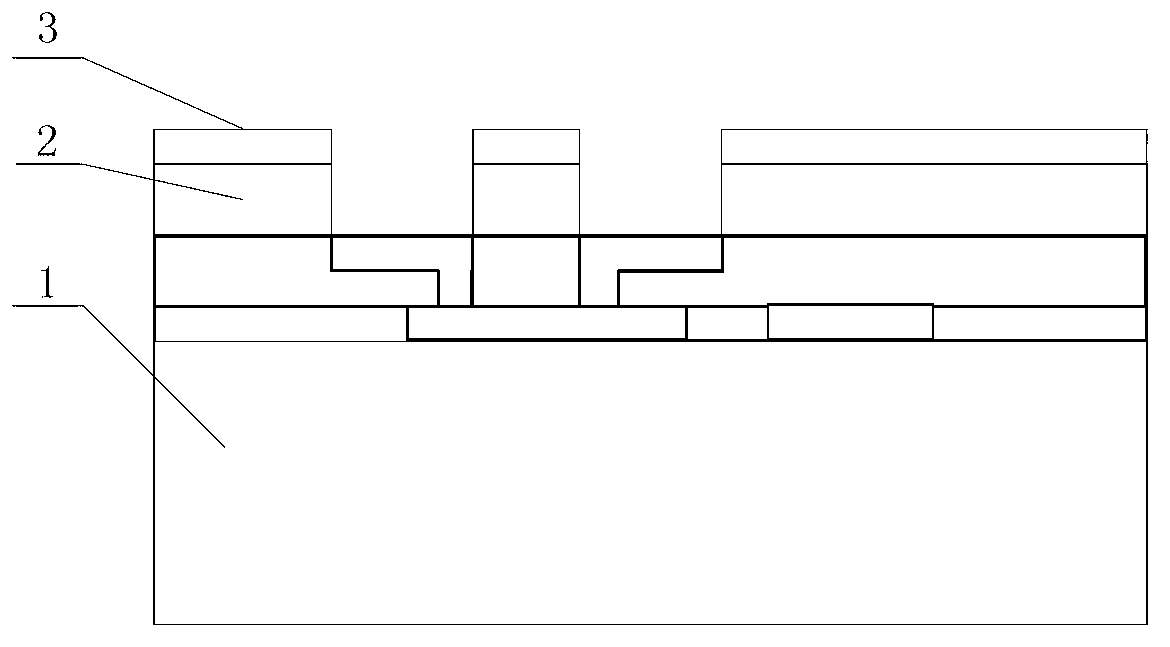

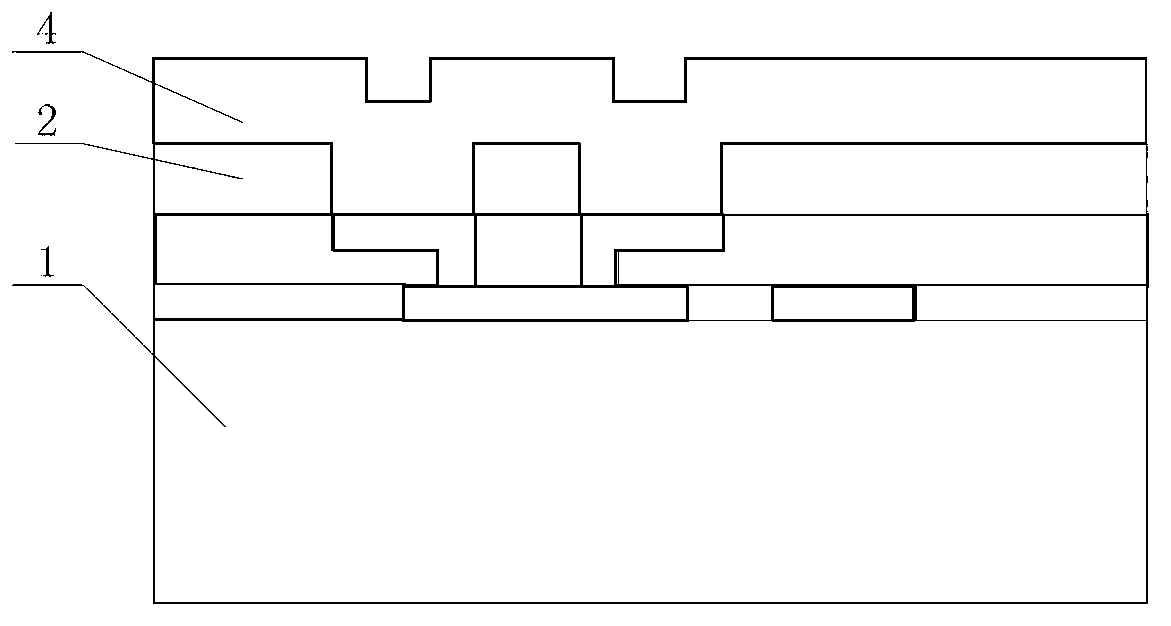

[0036] The existing microbump preparation technology includes deposition of metal seed layer, coating and exposure, electroplating and etching of metal seed layer, wherein coating and exposure, electroplating and etching of metal seed layer all affect the reduction of bump pitch. Especially in the etching of the seed layer, when the pitch of the bumps becomes smaller, the undercutting is very serious, causing the bumps to fall off, and further reducing the distance between the bumps is restricted.

[0037] In order to further reduce the distance between the micro-bumps, it is extremely important to overcome the undercut around the micro-bumps after the seed layer is etched. The invention adopts the improved damascene process flow to prepare the micro-bumps, avoids the wet etching process and has no bump undercutting phenomenon. The new process first deposits the silicon carbide etch stop layer and the electrolyte layer, coats the glue, etches holes in the electrolyte layer by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com