Hydraulic transfer method provided with design surface purification mechanism, and hydraulic transfer device therefor

An appearance surface and hydraulic technology, applied in transfer printing, rotary printing machine, ink transfer from original manuscript, etc., can solve the problems of time-consuming and poor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0402] The present invention takes the above-mentioned embodiment as a basic technical idea, but the following changes can also be considered.

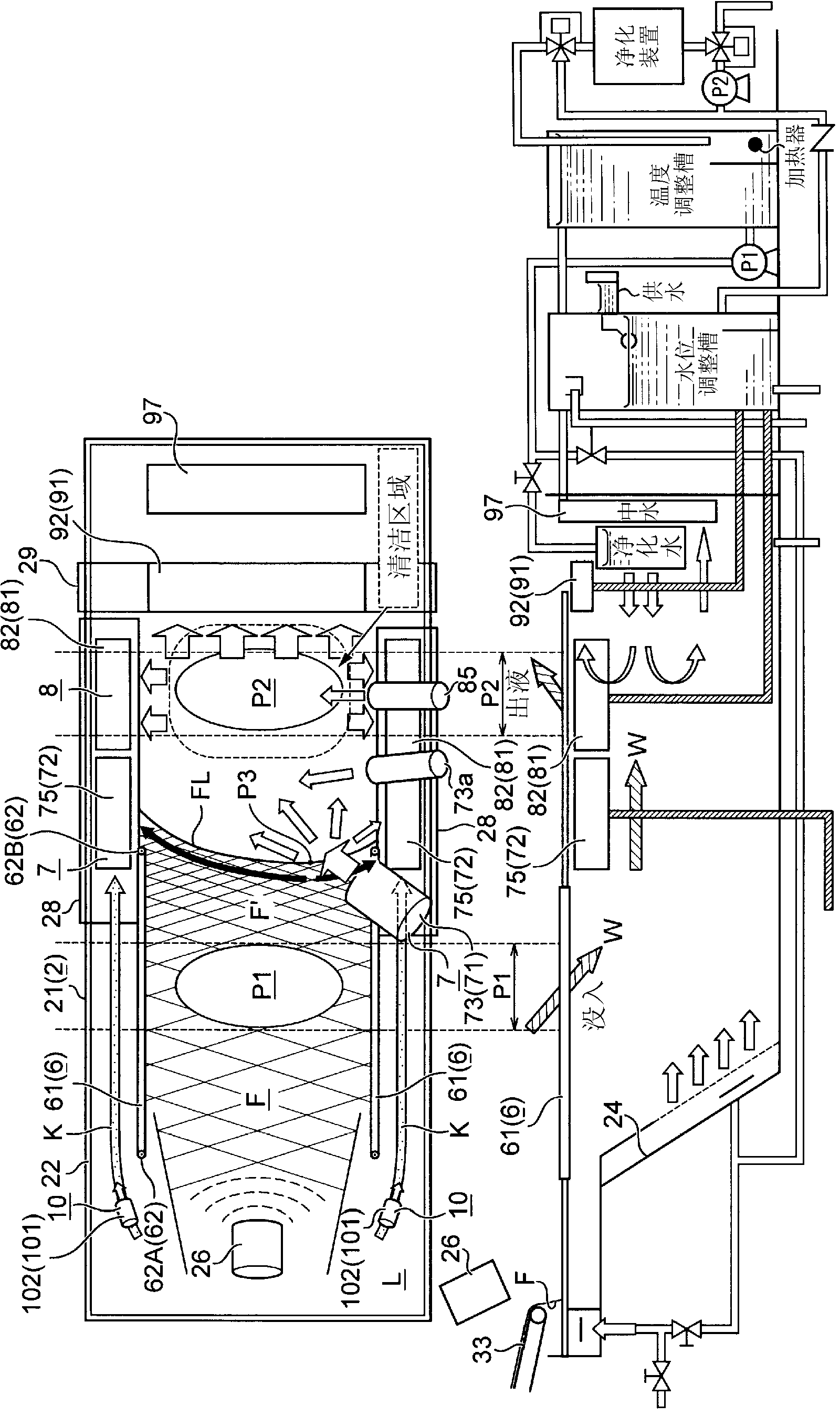

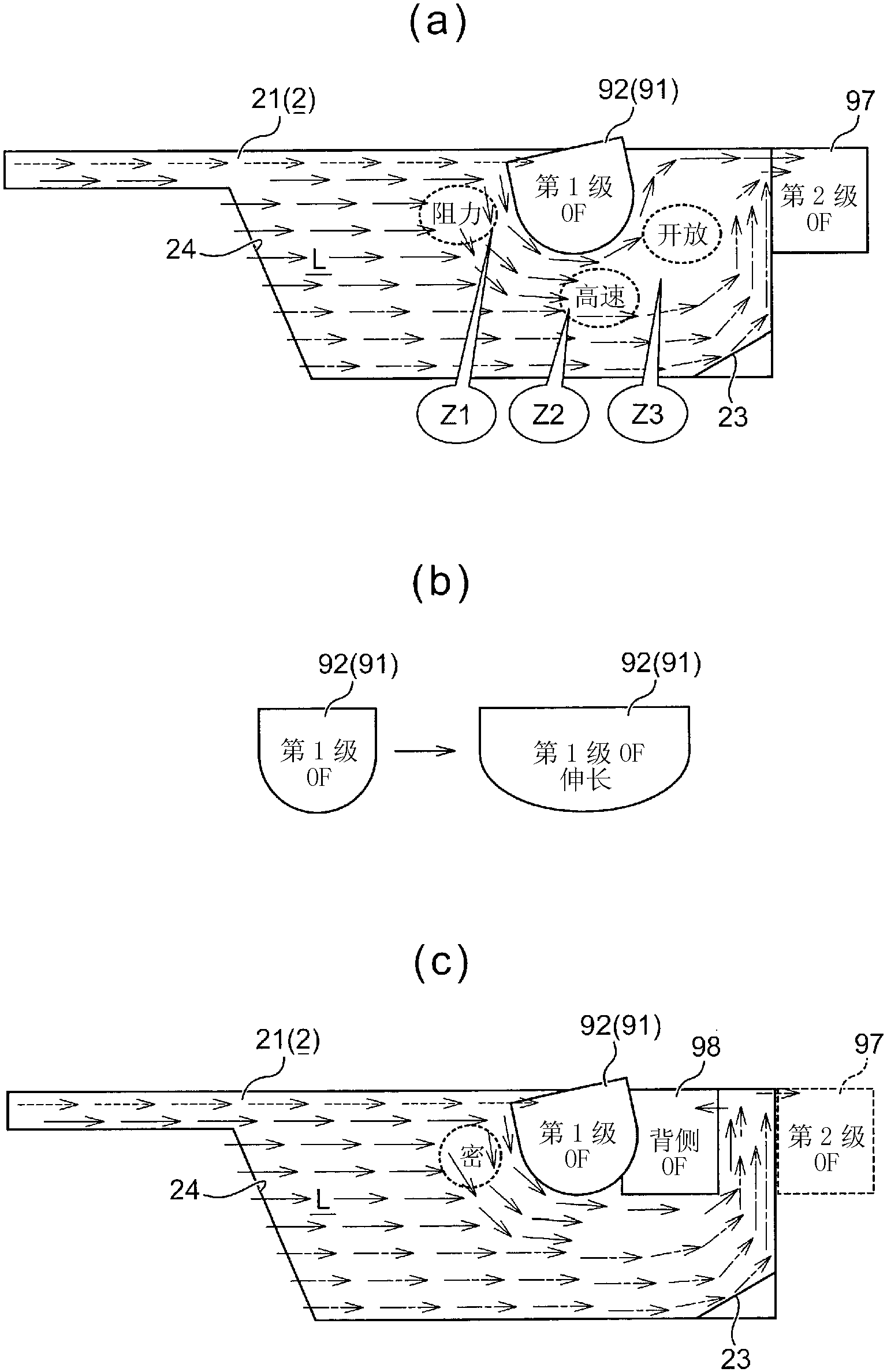

[0403] First of all, in the above-mentioned embodiment, the impurities in the transfer liquid L are efficiently recovered mainly by using the two-stage OF structure, and the cleaning of the liquid outlet area P2 is realized, but when the cleaning of the liquid outlet area P2 (transfer liquid L In the process of cleaning), it is not necessary to have a two-stage OF structure, and it may be as follows (this will be referred to as "other example 1").

[0404] That is, as an example Figure 24 ~ Figure 26As shown, this method (other embodiment 1) is provided with a new water supply port 107 below the overflow tank 92 used for forming the flow away from the appearance surface, and supplies new water upwards from here toward the liquid outlet area P2 (in other embodiments 1, the reference symbol "PU" is attached to the fresh water), and th...

Embodiment 2

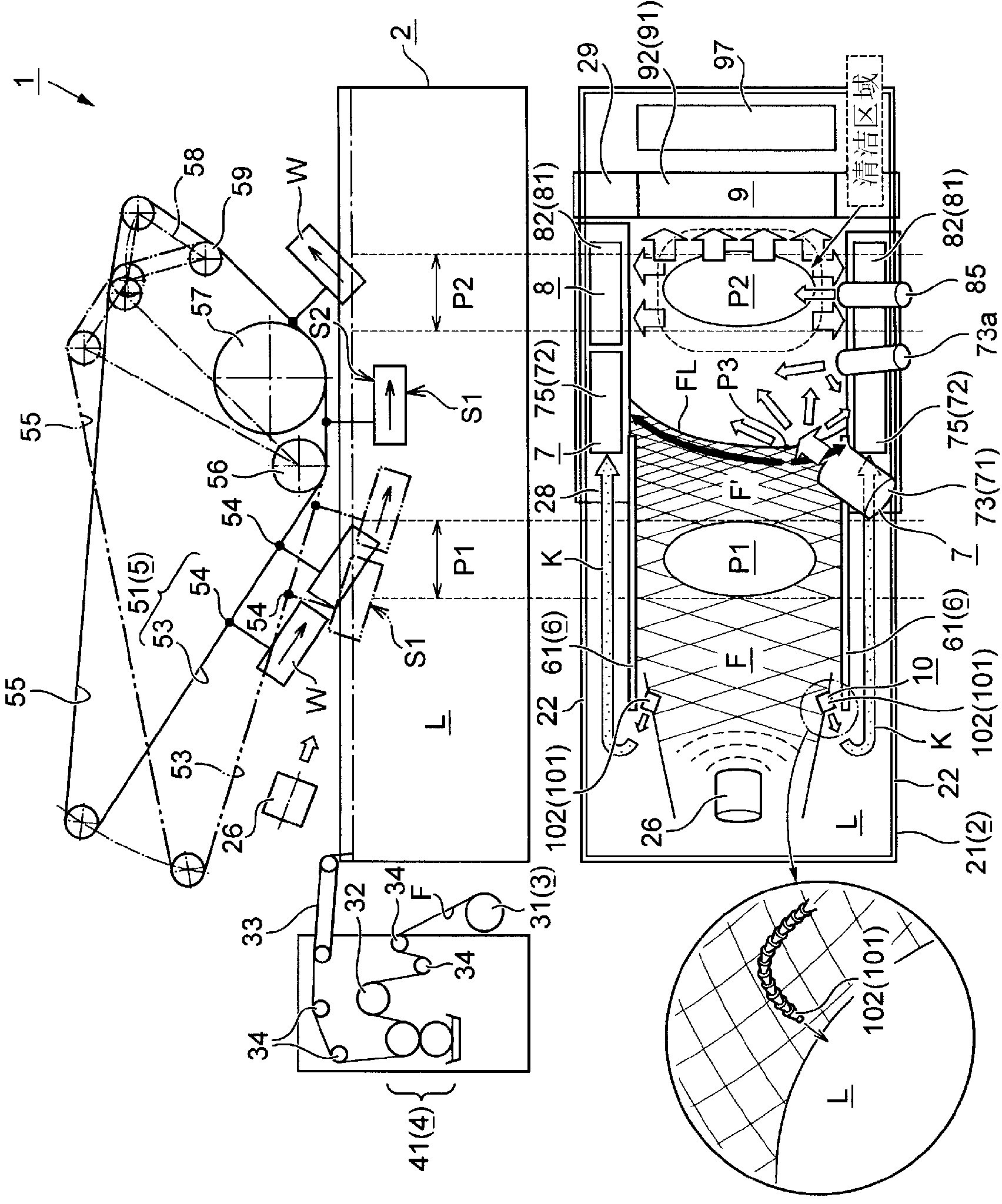

[0417] In addition, in the above-mentioned basic embodiment, the mode in which the active agent is coated on the transfer film F and then supplied to the transfer tank 2 is mainly shown (refer to figure 1 ), but the activation of the transfer film F as described above can also be carried out in the state of being supplied to the transfer tank 2 and in contact with the liquid. In this case, there is a preferred activation form corresponding to this. Therefore, This will be described below (this will be referred to as "other example 2"). That is, in other Example 2, the active agent application device (apparatus assigned reference numeral "4" in the basic embodiment) is changed so that the transfer film F supplied to the surface of the transfer liquid L of the transfer tank In the activated form, in particular, the reference numeral "active agent application device 40" is attached to the device to distinguish it from the basic embodiment. In addition, by the way, here, the hyd...

Embodiment 2

[0482] Embodiment (other embodiment 2: Figure 28 )

[0483] On the other hand, in the present system in which the drain water after mold release cleaning is supplied to the transfer tank 20, the mold release cleaning device 90 implements hot water spray 902 using two storage tanks 904 and a circulation pump and a flow rate of 20 L / min. Rinse water spray 903, import 15L / min release water (refer to Figure 28 ). The PVA concentration of the mold release water was 600 ppm after 3 hours and 1200 ppm after 8 hours.

[0484] The initial PVA concentration of the transfer tank 20 was adjusted to 500ppm, and the above-mentioned release water was introduced and the transfer process was continued. As a result, the PVA concentration of the transfer water after 8 hours was 1350ppm, 1700ppm after 16 hours, and 800ppm after 80 hours. 2000ppm, and 2040ppm after 160 hours, the transfer film characteristics were stable, and no defect caused by the transfer film F was found.

[0485] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com