Induction heating device, induction heating method, and program

An induction heating device and induction heating technology are applied in induction heating, induction heating control, electric heating devices, etc., which can solve the problems of increased conduction loss of switching elements, and achieve the effect of reducing surge voltage and reducing switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

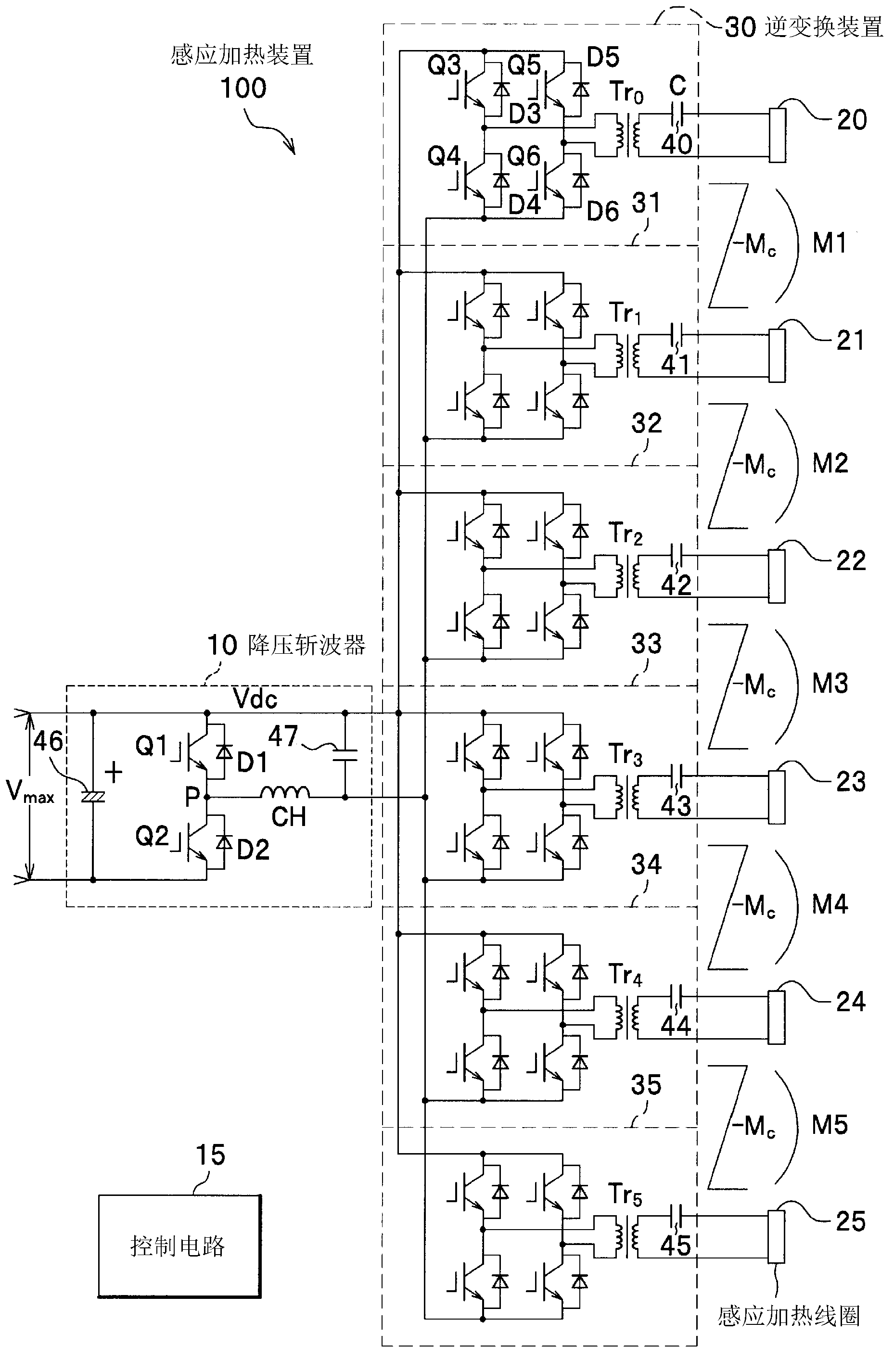

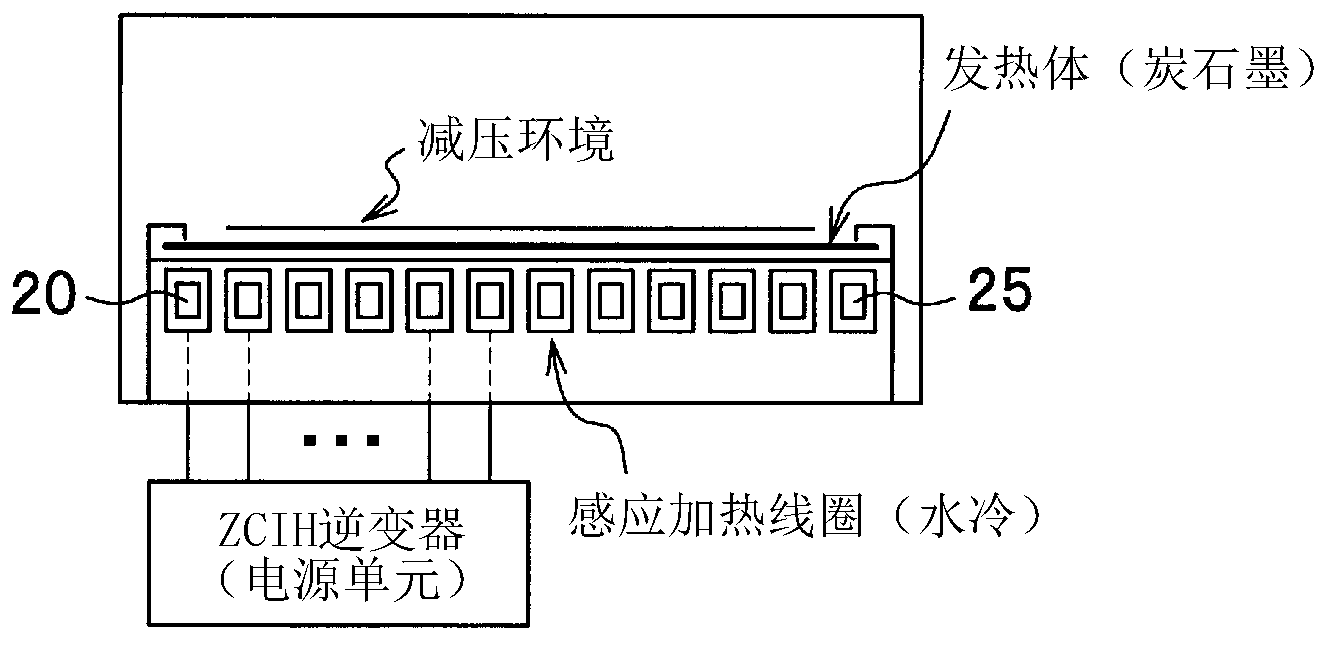

[0037] use figure 1 and figure 2 , the structure of the induction heating device of the present invention will be described.

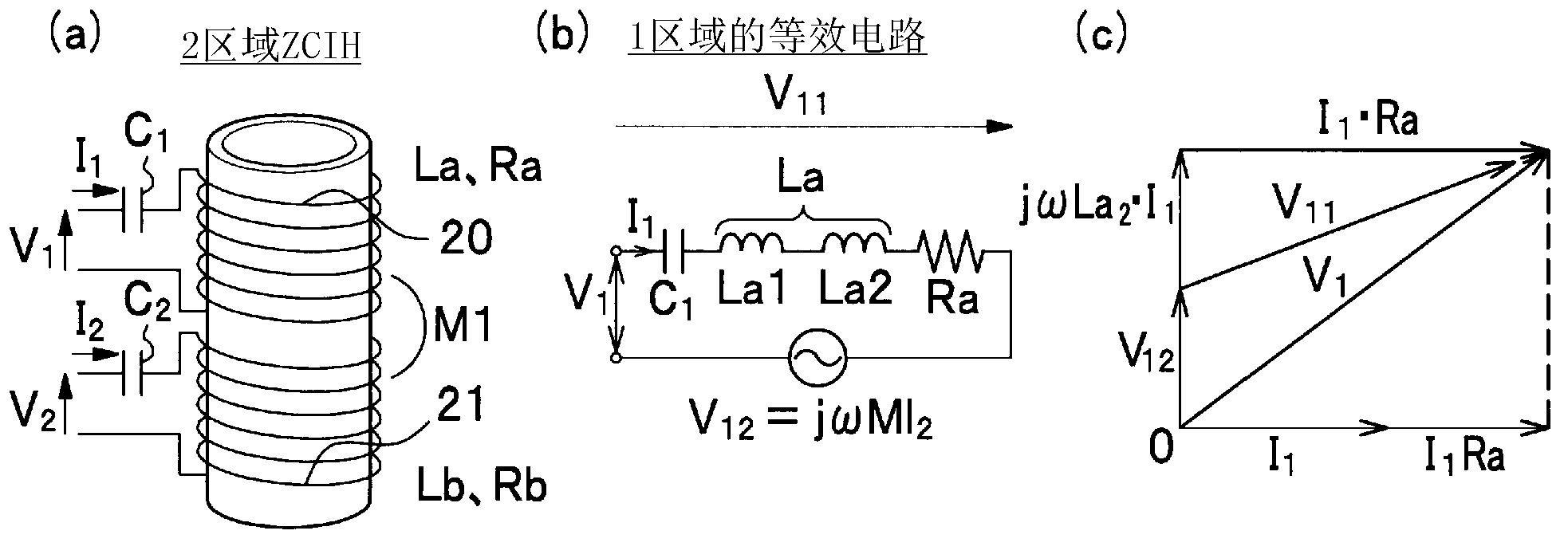

[0038] exist figure 1 Among them, the induction heating device 100 is provided with a step-down chopper 10, a plurality of inversion devices 30, 31, ..., 35, a plurality of induction heating coils 20, 21, ..., 25, and a control circuit 15, and each induction heating coil 20, 21, ..., 25 generate high-frequency magnetic flux in a common heating element (for example, carbon graphite) ( figure 2 ) flows through the eddy current to make the heating element generate heat.

[0039] In addition, the induction heating device 100 is controlled so that the current phases and frequencies of all the induction heating coils 20 , 21 , . Because the current phases of the induction heating coils 20, 21, . will not decrease. As a result, temperature unevenness does not occur on the surface of the object to be heated.

[0040] In addition, in order to reduce th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com