Vegetable cultivating machine

A cultivation machine and vegetable technology, applied in cultivation, greenhouse cultivation, climate change adaptation and other directions, can solve the problems of unbalanced absorption, inability to adjust the pH value of the cultivation environment, and difficulty in ensuring the deployment within a reasonable range required for crop growth, etc. To achieve the effect of improving planting effect and reducing planting risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the technical scheme of invention is described in detail:

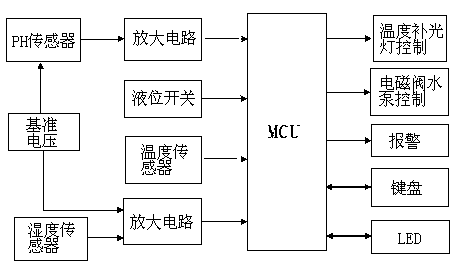

[0020] Such as figure 1 As shown, the control board includes MCU, temperature control module, pH control module, light control module, liquid level switch module, display module, water pump control module, temperature control module, pH control module, light control module, liquid level switch module , a display module, and a water pump control module are respectively connected to the MCU; wherein the pH control module includes a pH sensor to detect the pH value of the culture solution, one end of the pH sensor is connected to a reference voltage, and the output voltage signal of the pH sensor is amplified by an amplifier circuit and then output to the MCU; the temperature control module includes a temperature sensor, and the temperature sensor is connected to the MCU to measure the water temperature and the ambient temperature; the liquid level swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com