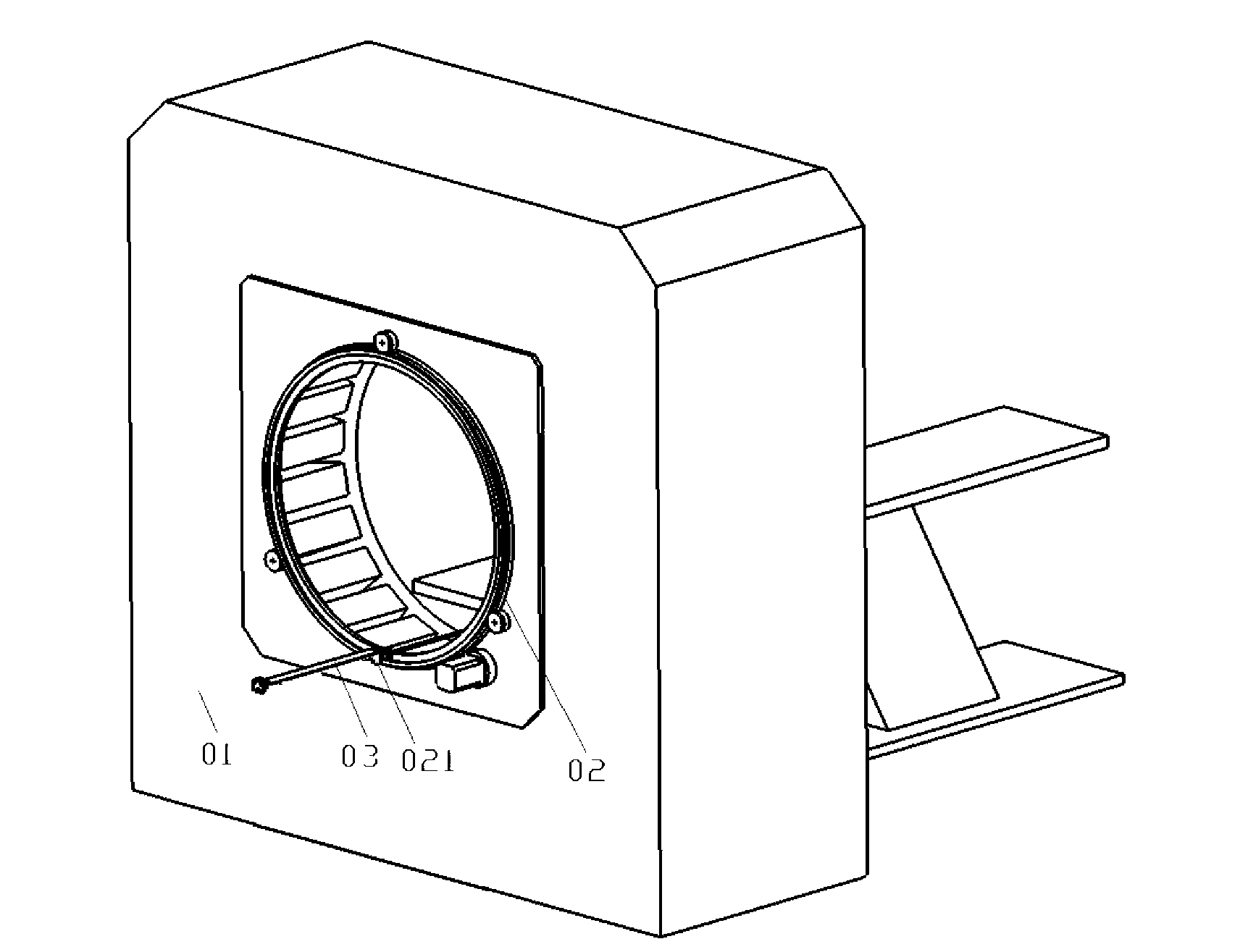

Scanning device of medical detector and automatic assembling and disassembling device for medical rod source

An automatic loading and unloading and scanning device technology, which is applied in the field of medical machinery, can solve problems such as large operating errors in manual operations, low reliability of rod source installation, and damage to operating technicians, so as to improve efficiency, avoid radiation damage, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

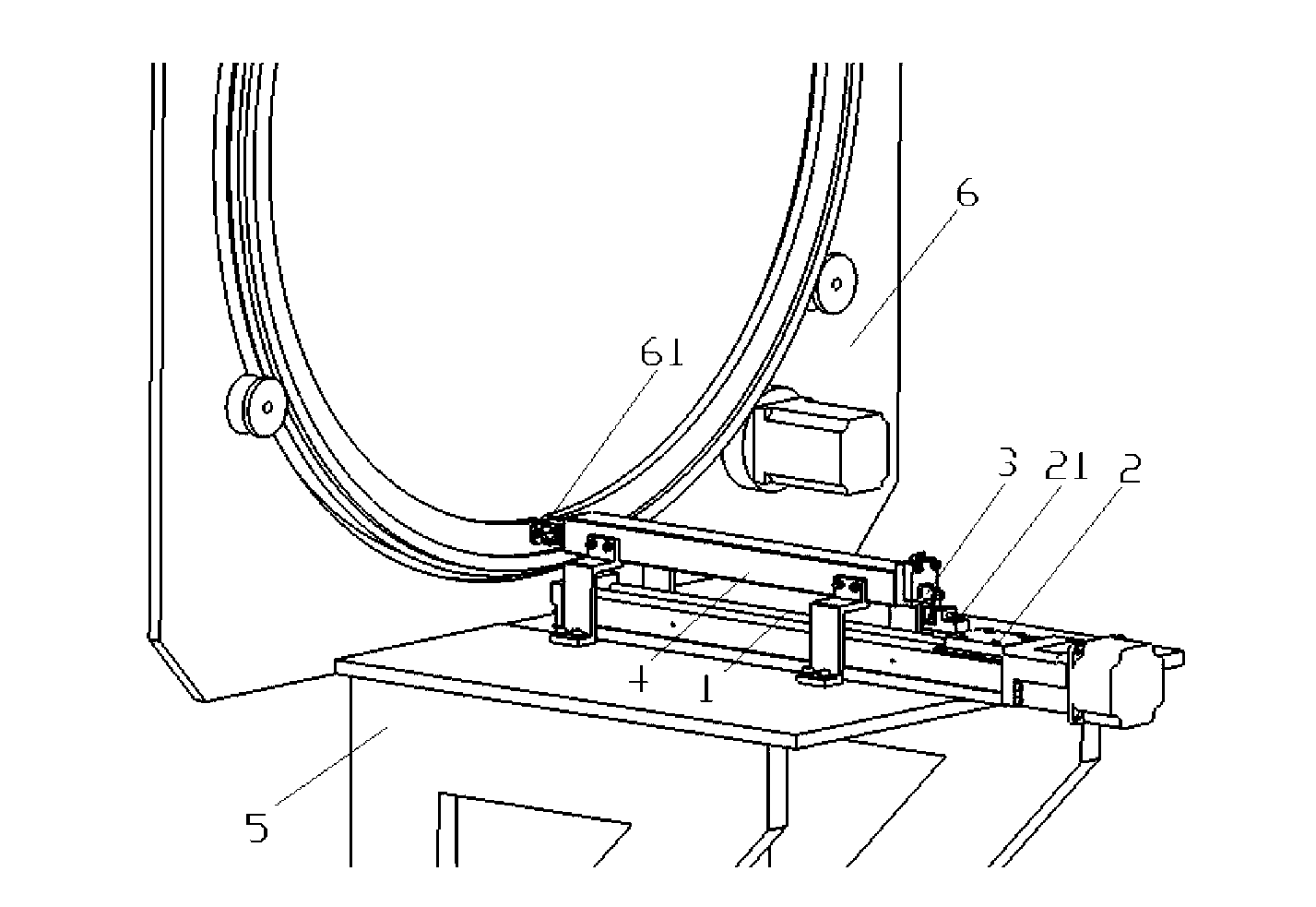

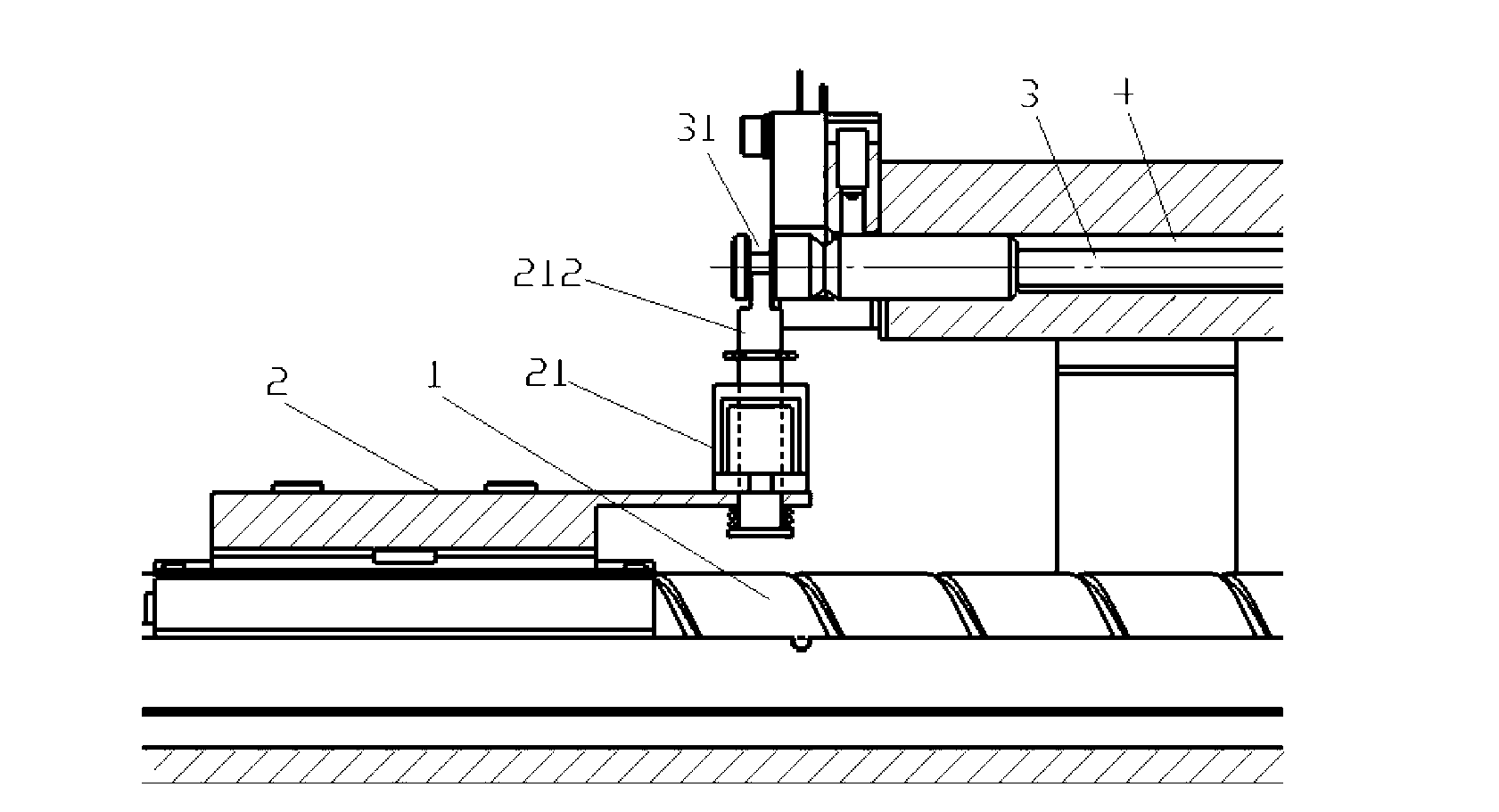

[0047] Please refer further Figure 3-7 , image 3 It is a cross-sectional view of the automatic loading and unloading device provided by the present invention before sending rods in the first embodiment; Figure 4 for image 3 The cross-sectional view of the automatic loading and unloading device shown in the rod feeding process; Figure 5 for image 3 The cross-sectional view of the automatic loading and unloading device shown after the rod feeding is completed; Image 6 for image 3 The cross-sectional view of the automatic loading and unloading device shown after the rod is unloaded; Figure 7 for adoption image 3 The flow chart of the automatic loading and unloading device for feeding and unloading rods is shown.

[0048] In the first embodiment, the electromagnet 21 can be provided with a collet 212 which can be attracted to the electromagnet 21 , and the collet 212 is arranged in cooperation with the tail of the rod source 3 .

[0049] When the electromagnet 21...

Embodiment 2

[0059] Please refer to Figure 8-Figure 11 , Figure 8 It is a cross-sectional view of the automatic loading and unloading device provided by the present invention before sending rods in the second specific embodiment; Figure 9 for Figure 8 The cross-sectional view of the automatic loading and unloading device shown after the rod feeding is completed; Figure 10 for Figure 8 The cross-sectional view of the automatic loading and unloading device shown after the rod is unloaded; Figure 11 for adoption Figure 8 The flow chart of the automatic loading and unloading device for feeding and unloading rods is shown.

[0060] In the second specific embodiment, the tail end of the rod source 3 is a steel structure, and the electromagnet 21 can have a suction part 211, and the suction part 211 can be attracted to the tail end of the rod source 3, thereby fixing the rod source 3 .

[0061] The suction part 211 can be a structure independently arranged on the electromagnet 21, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com