Water curtain type paint mist filter

A filter and water curtain technology, applied in chemical instruments and methods, separation of dispersed particles, use of liquid separation agents, etc., can solve problems such as increased investment costs, sewage discharge, and secondary pollution of the environment, achieving flexible and convenient installation, High purification efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

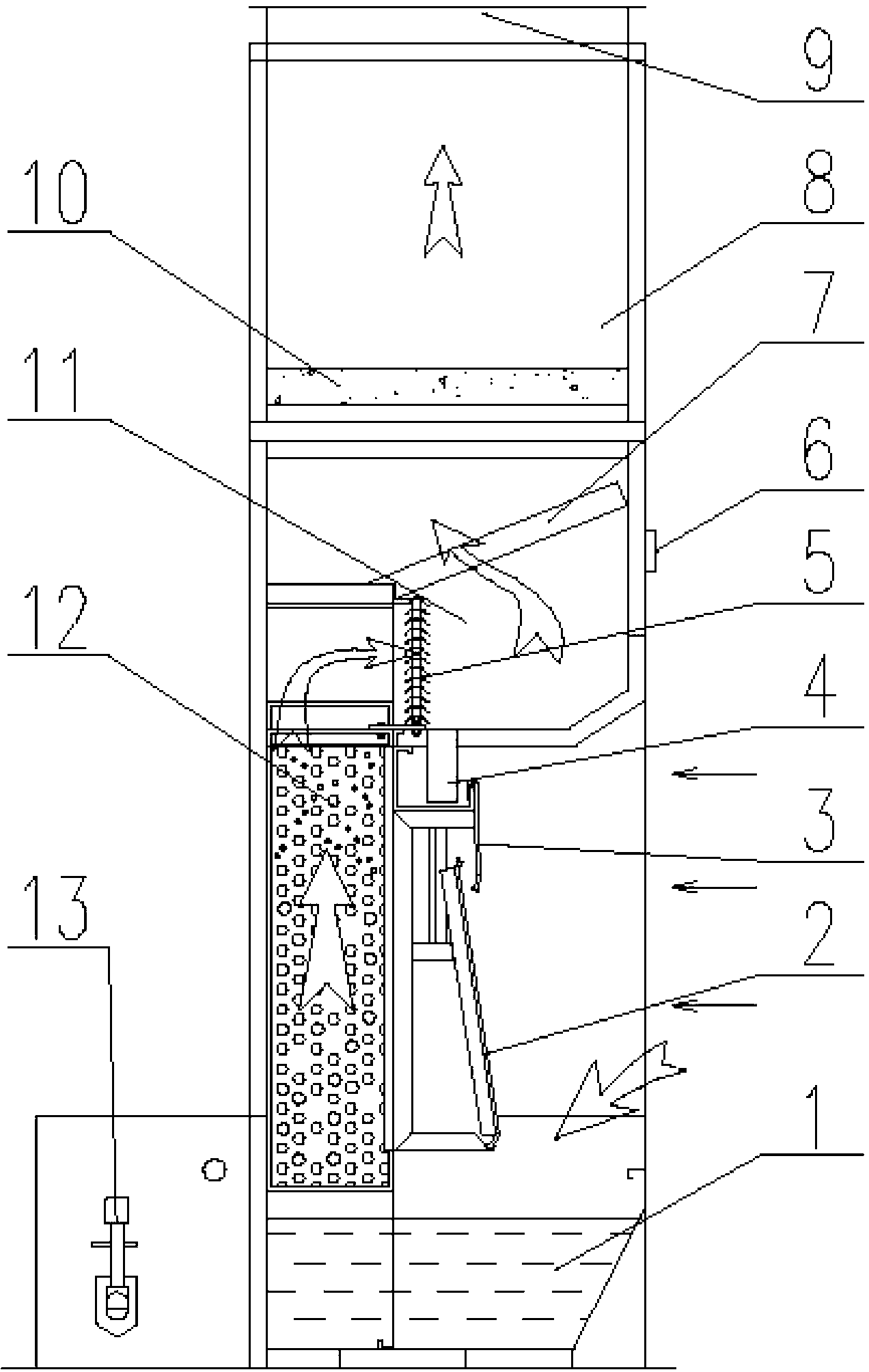

[0016] The embodiment of the present invention includes a water tank 1, an air collecting tank 11 and an exhaust static pressure tank 8, which are sequentially combined vertically upwards in series.

[0017] The side of the water tank 1 is provided with a paint mist inlet, and the top of the exhaust static pressure box 8 is provided with an air outlet 9; the water tank 1 and the gas collection box 11 are connected through the air-water mixing channel 12 located on the upper part of the water tank 1, and the gas collection An activated carbon filter plate 10 is arranged between the case 11 and the exhaust static plenum 8, and the air outlet 9 at the top of the exhaust static plenum 8 is externally connected with an exhaust fan.

[0018] The upper part of the water tank 1 is provided with upper and lower flashing plates 3, 2, and the gas collecting box 11 is provided with a diversion grid 5 and a water retaining plate 7, and the water retaining plate 7 is an orifice plate or a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com