Methods for preparing large-area graphene film and large-area graphene composite films

A graphene film, large-area technology, applied in graphene, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of high preparation cost, long suction filtration time, inconvenience, etc. The effect of flexibility and flatness, no pollution to the environment, and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Pour 150ml of graphene oxide aqueous solution with a mass concentration of 5mg / ml on flat commercial A4 printing paper, use a stainless steel rod rolling method to make the graphene oxide solution flow and form a layer of uniform coverage on the entire surface of the printing paper. Film layer, and then naturally dry and solidify at room temperature;

[0032] At room temperature, the printing paper bearing the graphene oxide film layer is soaked in hydrochloric acid with a molar concentration of 1 mol / L. The graphene oxide film layer will be easily peeled off from the printing paper in minutes, and an A4-sized graphene oxide film can be obtained after drying; this film has good flexibility and can be curled at will;

[0033] Then, the graphene oxide film can be soaked again at room temperature in 45% hydroiodic acid to perform a reduction reaction, thereby obtaining the desired graphene film product.

Embodiment 2

[0035] Pour 150ml of graphene oxide aqueous solution with a mass concentration of 10mg / ml on flat commercial A4 printing paper, use a stainless steel rod rolling method to make the graphene oxide solution flow and form a layer of uniform covering film on the entire surface of the printing paper layer, and then naturally dry and solidify at room temperature;

[0036]At room temperature, the printing paper bearing the graphene oxide film layer is soaked in acetic acid with a molar concentration of 0.5mol / L. The graphene oxide film layer will be easily peeled off from the printing paper in 10 minutes, and an A4-sized graphene oxide film can be obtained after drying; this film has good flexibility and can be curled at will;

[0037] Then, the graphene oxide film can be soaked again at room temperature in 50% hydroiodic acid to perform a reduction reaction, thereby obtaining the desired graphene film product.

Embodiment 3

[0039] Pour 300ml of graphene oxide aqueous solution with a mass concentration of 0.1mg / ml on a flat drawing paper with a specification of 35cm*35cm, use a stainless steel rod rolling method to make it flow and form a layer of uniform coverage on the entire surface of the drawing paper film layer, and then carry out drying and curing treatment;

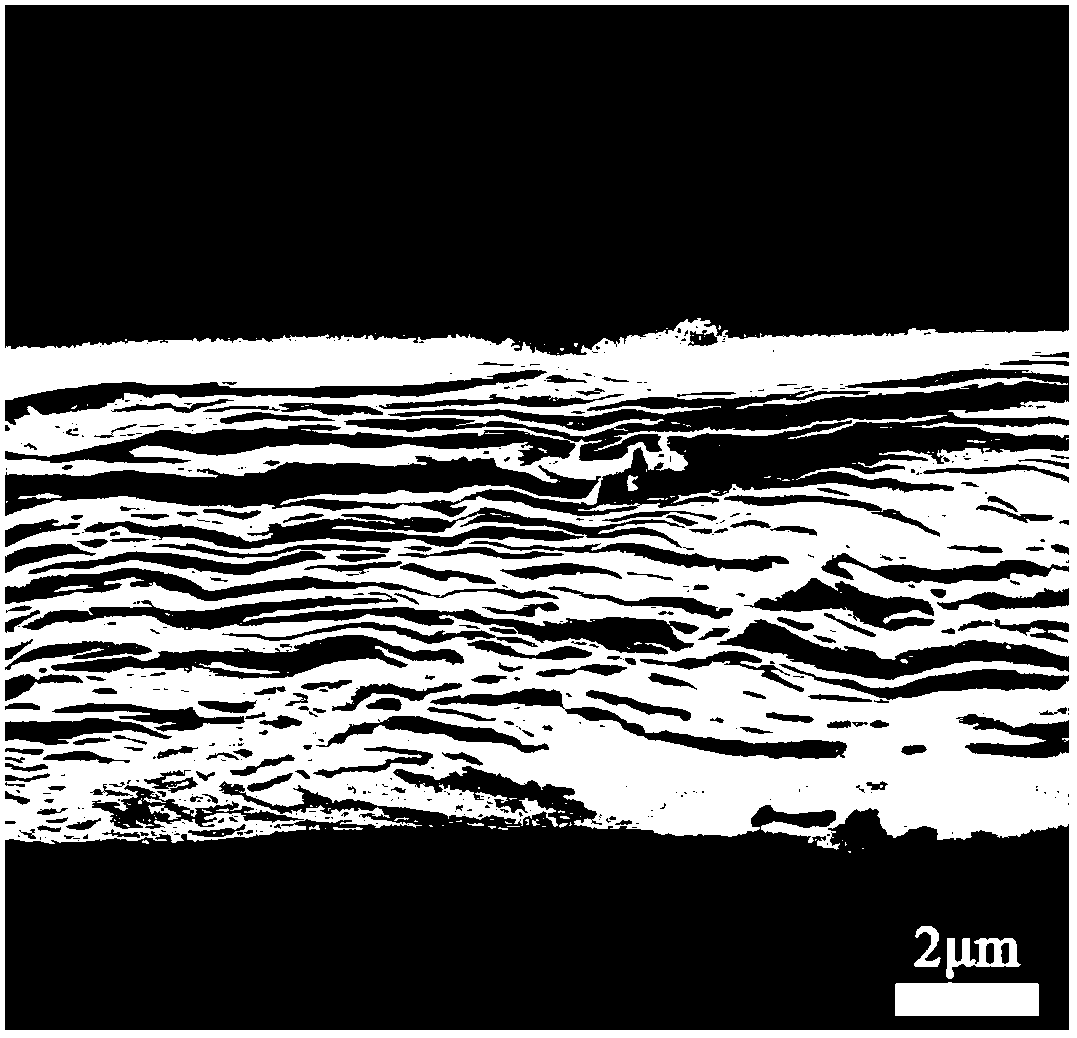

[0040] At room temperature, the drawing paper bearing the graphene oxide film layer is directly immersed in 55% hydroiodic acid to perform the reduction reaction. During the reduction process, the drawing paper is hydrolyzed and reacts with hydroiodic acid to generate bubbles. This impels the graphene film layer to break away from the drawing paper automatically, and obtains the desired large-area graphene film product. The cross-sectional SEM image of the prepared large-area graphene film is shown in figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com