Magnetic internally-circulating fluidized bed adsorber

A technology of internal circulation and adsorber, which is applied in the field of magnetic internal circulation fluidized bed adsorber, can solve the problems of difficult solid-liquid separation in fluidized bed, decrease of specific surface area, decrease of adsorption efficiency, etc., and achieve large solid-liquid contact area, transmission The effect of fast quality and small amount of adsorbent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

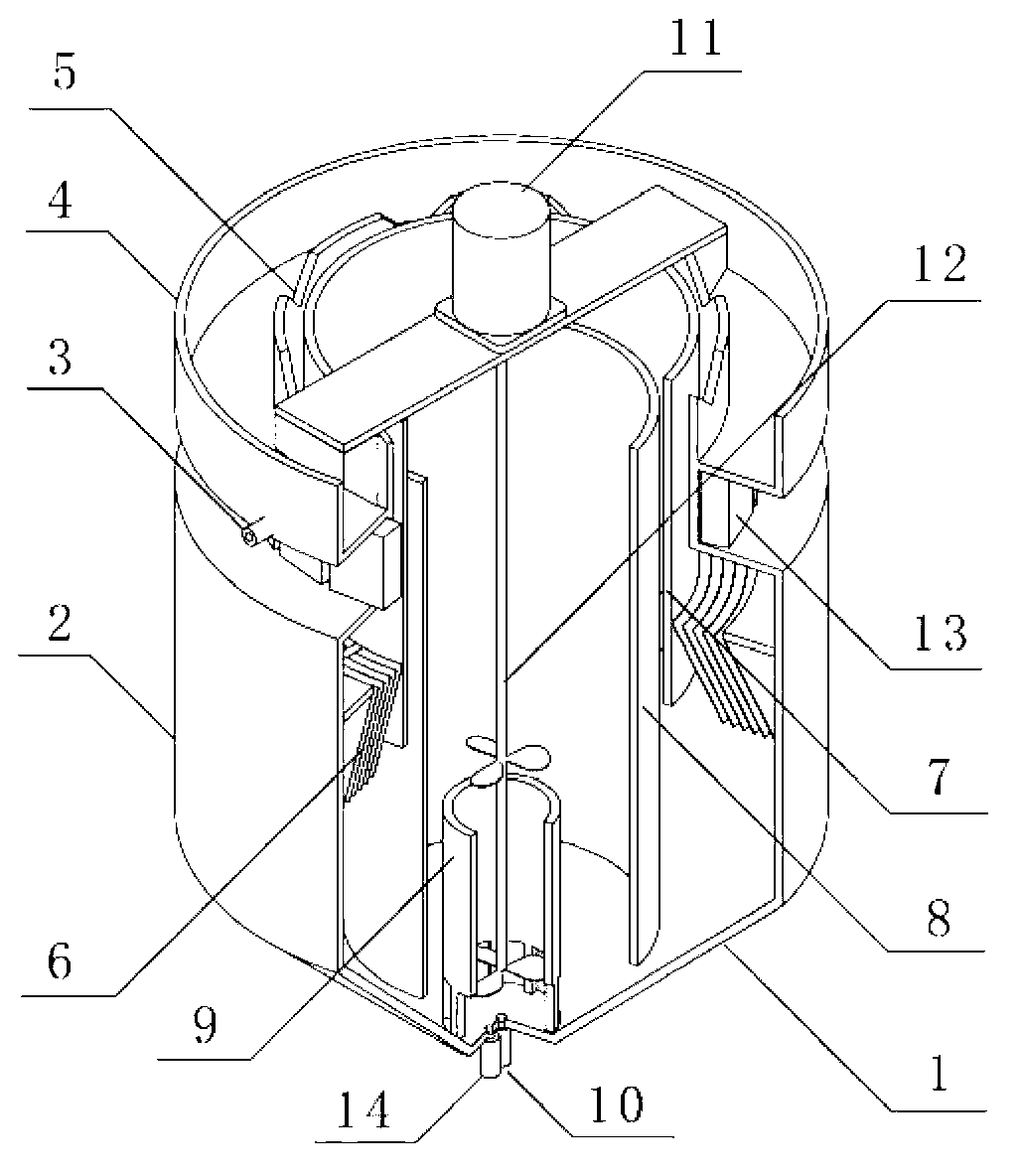

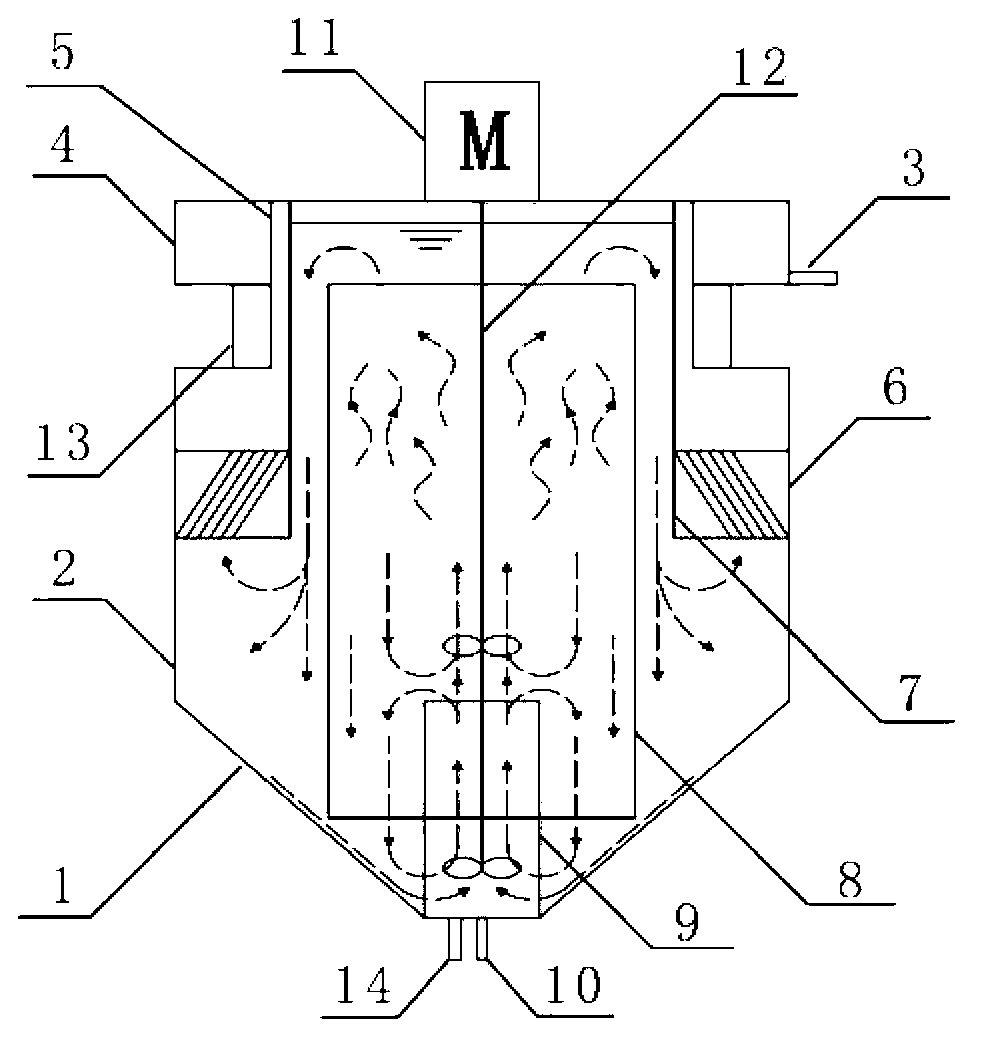

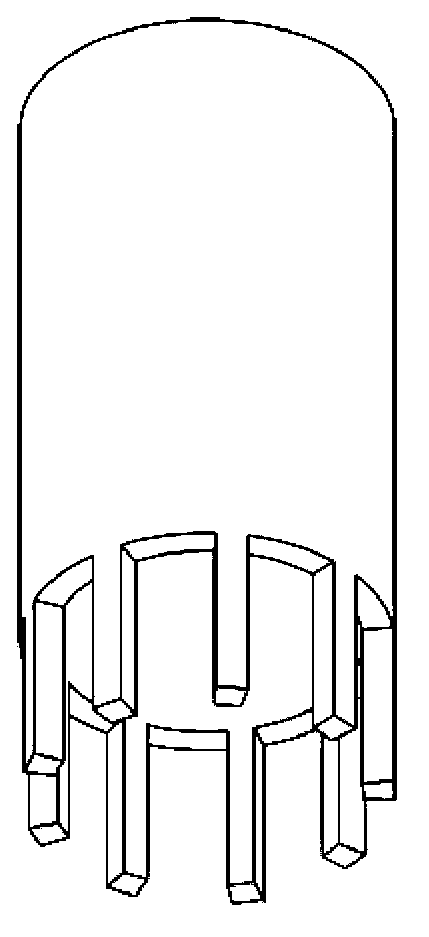

[0022] Such as figure 1 Shown: a magnetic internal circulating fluidized bed adsorber, including a vertebral body 1, a cylinder body 2, an outlet pipe 3, a water collection tank 4, an overflow weir 5, an inclined plate 6, an outer guide cylinder 7, and an intermediate cylinder body 8 , inner guide tube 9, water inlet pipe 10, motor 11, stirring paddle 12, magnet 13 and adsorbent discharge pipe 14; On the side of the water inlet pipe 10 at the bottom, the upper edge of the inner guide tube 9 is on the same level as the upper edge of the cone 1, the upper edge of the middle cylinder 8 is on the same level as the bottom of the sump 4, and the inner guide tube 9 is on the same level as the cone 1. Fixed connection, the middle cylinder body 8, the outer guide tube 7 and the inclined plate 6 are fixedly connected with the cylinder body 2, the lower edge of the middle cylinder body 8 is lower than the upper edge of the inner guide tube 9; the lower end of the inner guide tube 9 is ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com