Method for preparing 2,6-dimethyl naphthalene by alkylation reaction of MgAPO-11 molecular sieve catalytic naphthalene

A molecular sieve catalyzed naphthalene and alkylation reaction technology, which is applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of shortening crystallization time, facilitating large-scale production, and appropriate strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

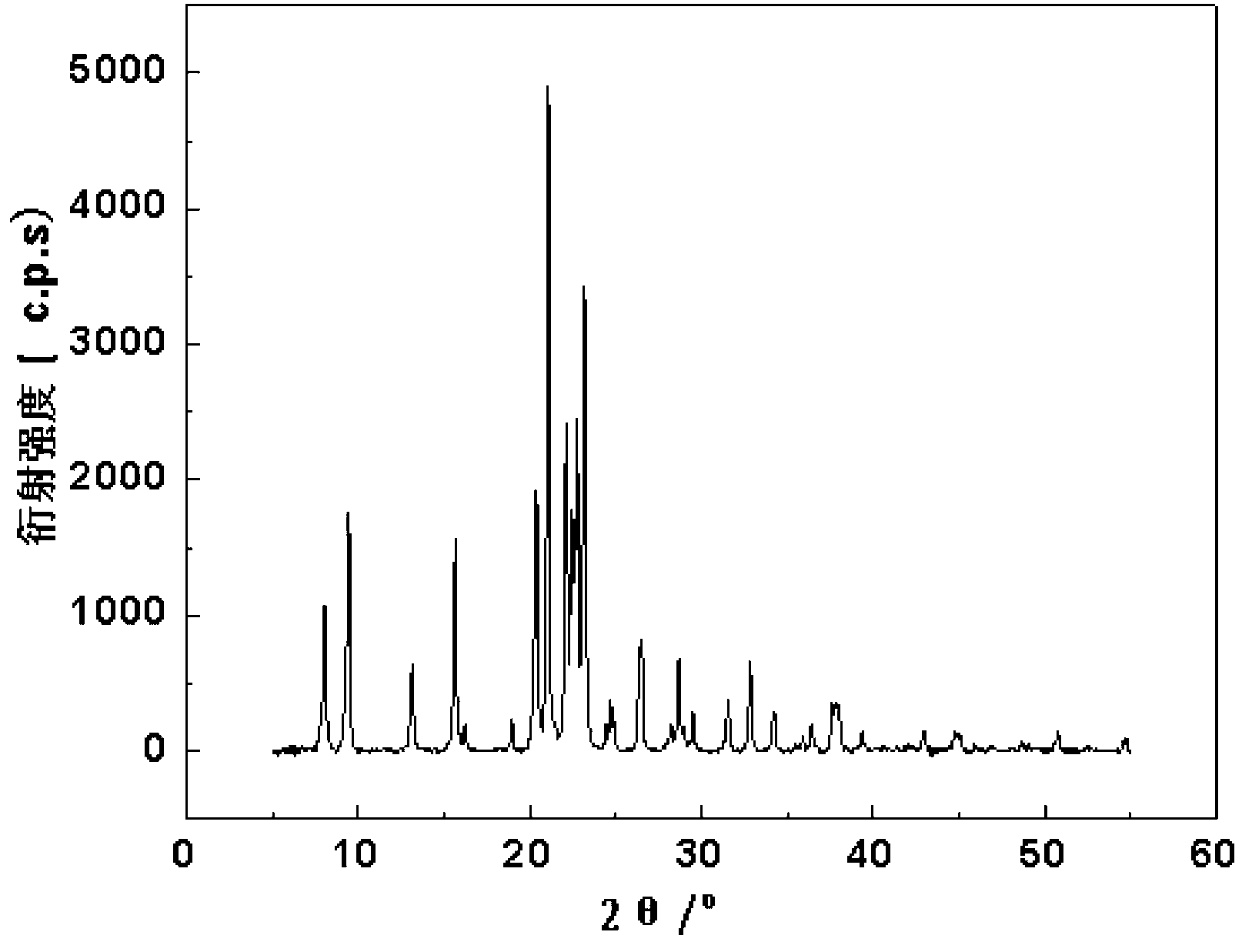

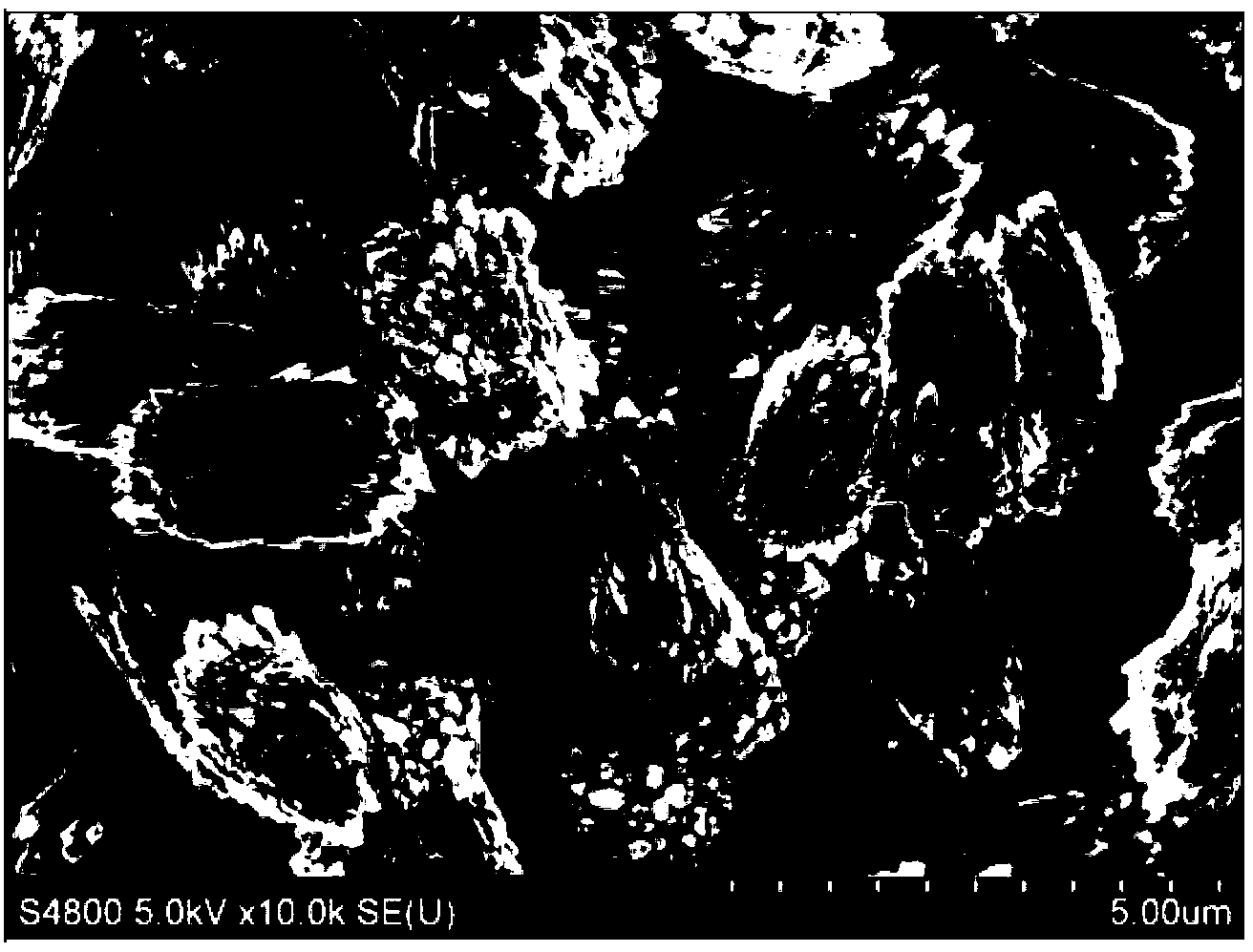

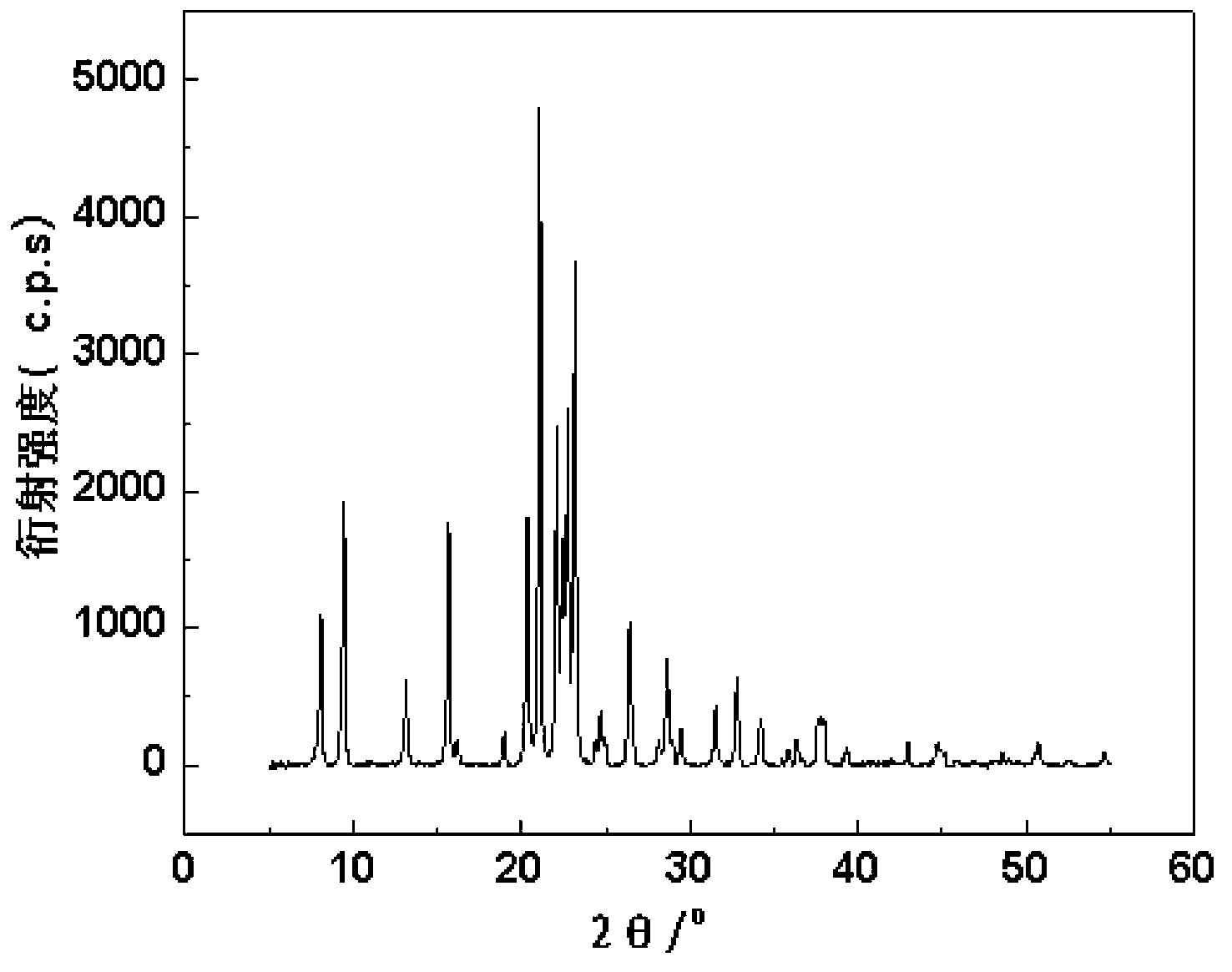

Image

Examples

specific Embodiment approach 1

[0026] Specific embodiment one: the method for preparing 2,6-dimethylnaphthalene by the alkylation reaction of naphthalene catalyzed by MgAPO-11 molecular sieve in this embodiment is realized according to the following steps:

[0027] 1. Put 20-40 mesh MgAPO-11 molecular sieves into the constant temperature zone of the stainless steel reaction tube of the fixed-bed microreactor, activate it for 2 hours at a temperature of 550°C and a nitrogen flow rate of 10ml / min, and then cool down to 350-450 ℃, and the activated MgAPO-11 molecular sieve is placed in the catalyst bed of the fixed-bed microreactor;

[0028] 2. Mix naphthalene, alkylating agent and solvent in a molar ratio of 1: (2-4): (6-12) to make a raw material liquid, then use a metering pump to continuously inject the raw material liquid into the catalyst of the fixed-bed microreactor Alkylation reaction between the bed layer and the activated MgAPO-11 molecular sieve, the reaction temperature is 350-450°C, the pressure ...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the magnesium source of MgAPO-11 molecular sieve described in step one is Mg(NO 3 ) 2 ·6H 2 O or Mg(CH 3 COO) 2 4H 2 O. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that MgO and Al in the MgAPO-11 molecular sieve described in step one 2 o 3 The molar ratio is (0.01~0.40):1. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com