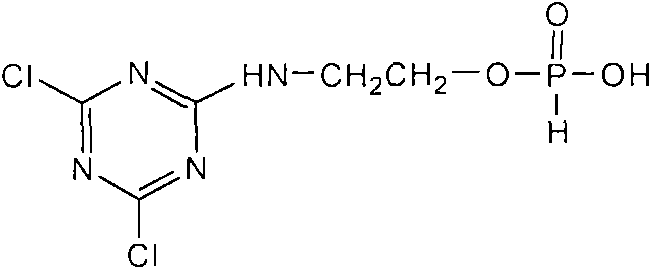

Preparation method of novel flame retardant for cotton

A flame retardant, a new type of technology, applied in the field of new printing and dyeing auxiliaries, to achieve the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

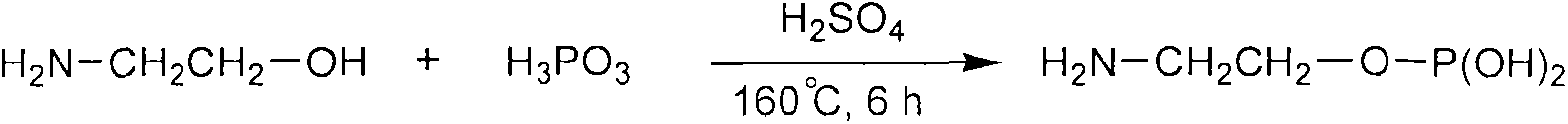

[0021] (1) Synthetic of monoethanolamine phosphite: first 82g (1mol) phosphorous acid is joined in the reaction container that has water separation reflux device, then the ethanolamine solution of 61g (1mol) is slowly added dropwise, stirs at room temperature, then 1 g (0.01 mol) of concentrated sulfuric acid (mass fraction 98%) was added dropwise as a catalyst for the esterification reaction, stirred at room temperature for 10 minutes, and then reacted at 160° C. for 6 hours with an oil bath as a heating medium. After the reaction was finished, 91 g of viscous yellow liquid product monoethanolamine phosphite was obtained, with a yield of 72.8%.

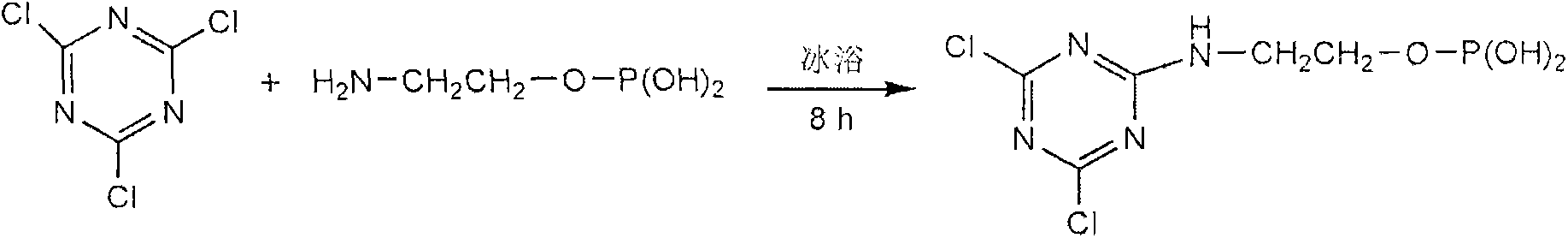

[0022] (2) Synthesis of phosphite containing s-triazine active group: 63g (0.5mol) monoethanolamine phosphite is dissolved in 150mL (0.1mol) mass fraction of 6% sodium carbonate aqueous solution, the solution is placed Stir in the ice bath until uniform, then add 92g (0.5mol) cyanuric chloride in the reaction vessel, stir and react i...

Embodiment 2

[0029] (1) Synthesis of monoethanolamine phosphite: first add 99g (1.2mol) of phosphorous acid into a reaction vessel with a water separation and reflux device, then slowly add 73g (1.2mol) of ethanolamine solution dropwise, and stir evenly at room temperature , then dropwise added 2.4g (0.024mol) of concentrated sulfuric acid (mass fraction 98%) as a catalyst for the esterification reaction, stirred at room temperature for 10 minutes, and then reacted at 160° C. for 6 hours with an oil bath as a heating medium. After the reaction was finished, 113 g of viscous yellow liquid product monoethanolamine phosphite was obtained, with a yield of 75.5%.

[0030] (2) Synthesis of phosphite containing s-triazine active group: 76g (0.6mol) monoethanolamine phosphite is dissolved in 180mL (0.12mol) mass fraction of 6% sodium carbonate aqueous solution, the solution is placed Stir in the ice bath until uniform, then add 110g (0.6mol) cyanuric chloride into the reaction vessel, stir and rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com