Powder spraying desulfuration mechanism for performing RH (Ruhrstahl and Heraeus) on molten steel

A powder spraying and molten steel technology, applied in the field of metallurgy, can solve the problems of difficult control of desulfurization agent usage, difficult control of injection speed, unstable injection speed, etc., and achieve the effect of high degree of automation, adjustable injection height and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

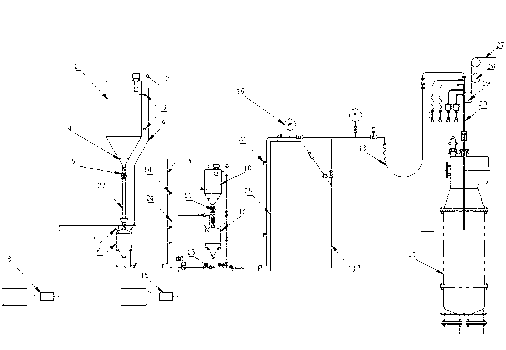

[0019] In order to overcome the problems of unstable injection speed, difficult control of the amount of desulfurization agent used, difficult control of injection speed and low desulfurization efficiency existing in the existing powder spraying technology, this embodiment provides a figure 1 The shown powder spraying desulfurization mechanism (system) for RH molten steel refining includes a desulfurizer delivery system and an injection system. 4 (to ensure the stable delivery of desulfurization agent), the first rotary feeder 5, pneumatic delivery tank 6, receiving bin 10, the second rotary feeder 11, spray tank 12 (to ensure accurate and stable delivery of desulfurization agent) , weighing device 13 (weighing the weight of powder required for each blowing), nitrogen module 8 (to remove the air in the desulfurizer storage bin) and argon module 15 (the conveying gas is argon, which does not contact with molten steel will cause a chemical reaction and cause changes in the prope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com