Preparation method of plastic-based copper-chromium double-layered environmental-friendly wear-resisting electronic hardware fitting

A plastic-based, double-layer technology, applied in metal material coating process, coating, superimposed layer plating, etc., can solve problems such as skin allergies, nickel metal sensitivity, poor bonding force, etc., and achieve high wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various aspects of the present invention Modifications in equivalent forms all fall within the scope defined by the appended claims of this application.

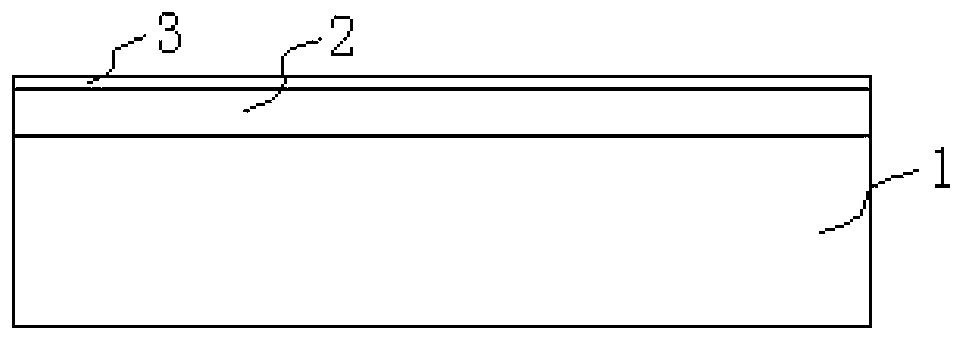

[0015] Such as figure 1 As shown, the substrate 1 of the electronic hardware workpiece of the ABS base material is pre-treated to form a chemical nickel layer on the workpiece, and then electroplated in copper pyrophosphate with a small current to obtain a 0.1-0.5 micron pyrocopper coating, and then coated with copper sulfate Electroplate in the solution for 5 minutes to obtain an acid copper plating layer of about 4 microns, and the thickness of the copper layer 2 durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com