Thermal-insulation guide support for large-caliber directly-buried tube

A technology for guiding brackets and pipes, applied in the directions of pipeline brackets, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of inconvenient installation of thermal insulation layers, large friction and noise, easy aging, falling off, etc., and achieve tight bonding , reduce vibration, create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific drawings.

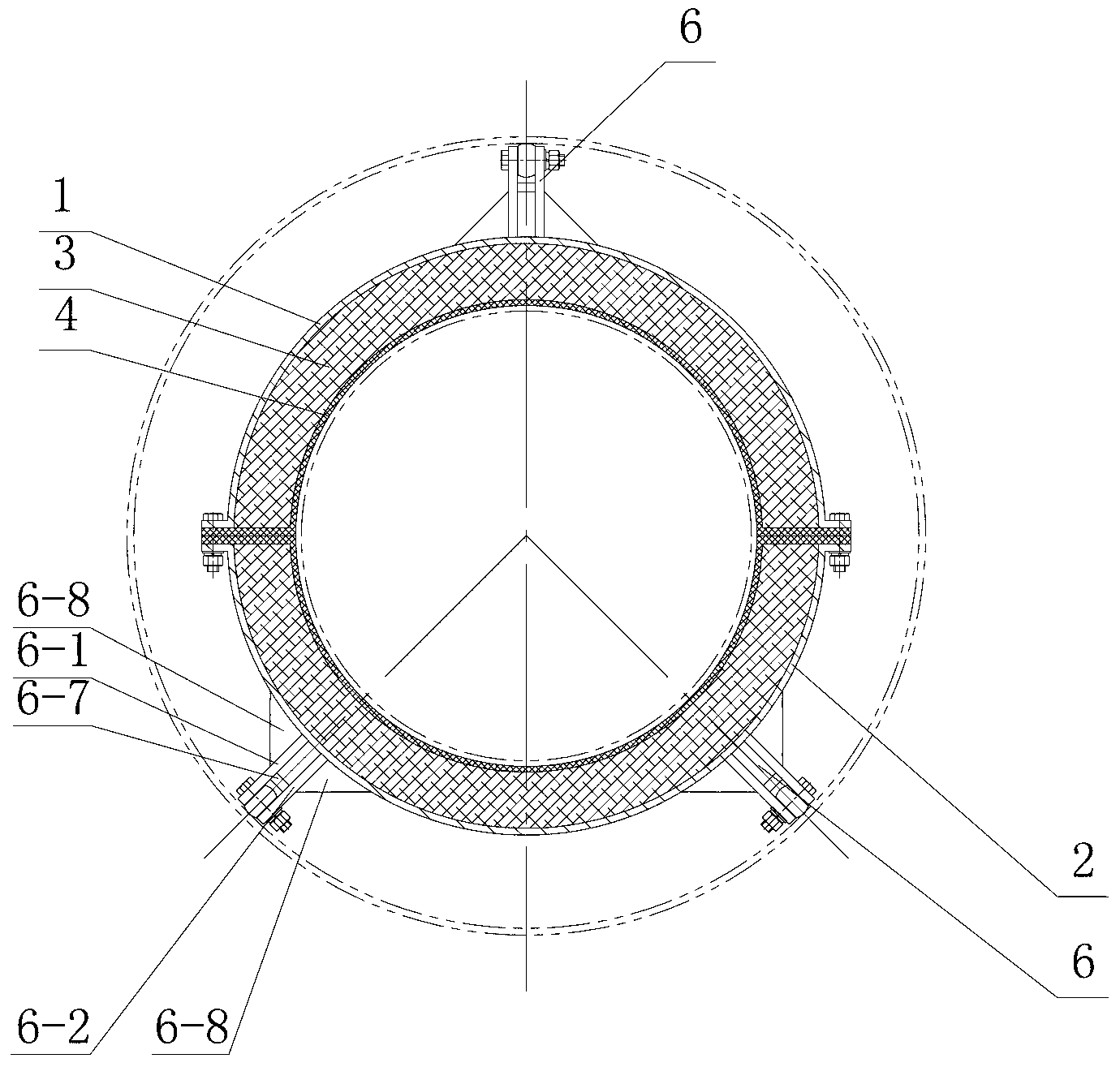

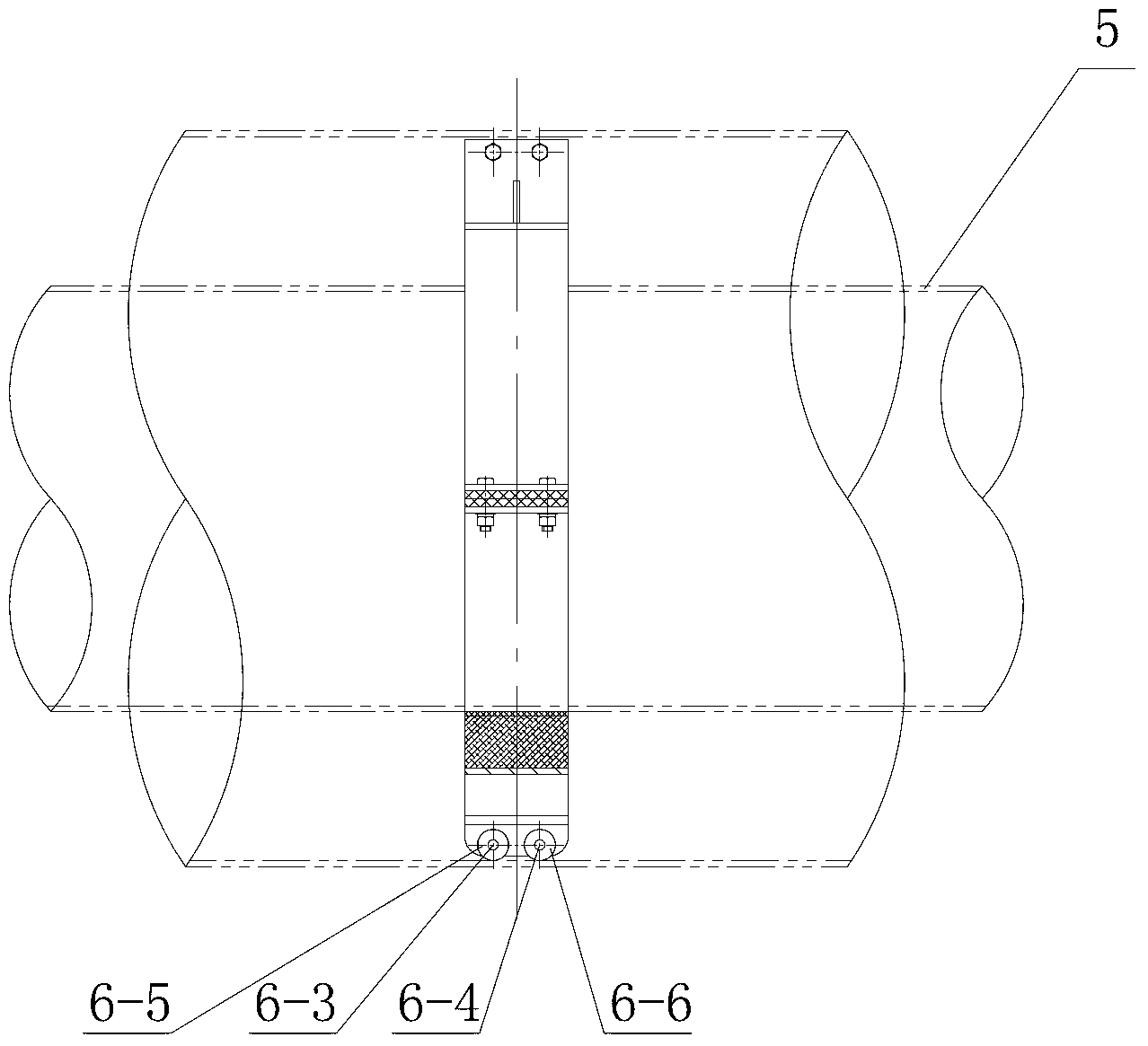

[0014] like figure 1 , figure 2 As shown: the heat insulation guide bracket for large-diameter direct buried pipe includes upper pipe clamp 1, lower pipe clamp 2, hard heat insulation layer 3, soft heat insulation layer 4, core pipe 5, double roller structure 6, first support Plate 6-1, second support plate 6-2, first roller shaft 6-3, second roller shaft 6-4, first roller 6-5, second roller 6-6, shin plate 6-7, rib Plates 6-8 etc.

[0015] The present invention includes a pipe clip body, which is formed by connecting an upper pipe clip 1 and a lower pipe clip 2; the upper pipe clip 1 and the lower pipe clip 2 are semicircular, and the upper pipe clip 1 and the lower pipe clip 2 are connected to form a ring structure; the inner arc surfaces of the upper pipe clamp 1 and the lower pipe clamp 2 are provided with a hard heat insulation layer 3, and one side of the hard heat i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com