Burner for a glass melting furnace comprising cooling

A glass melting furnace and burner technology, applied in the direction of burners, glass furnace equipment, gas fuel burners, etc., can solve problems such as cracking and injector blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

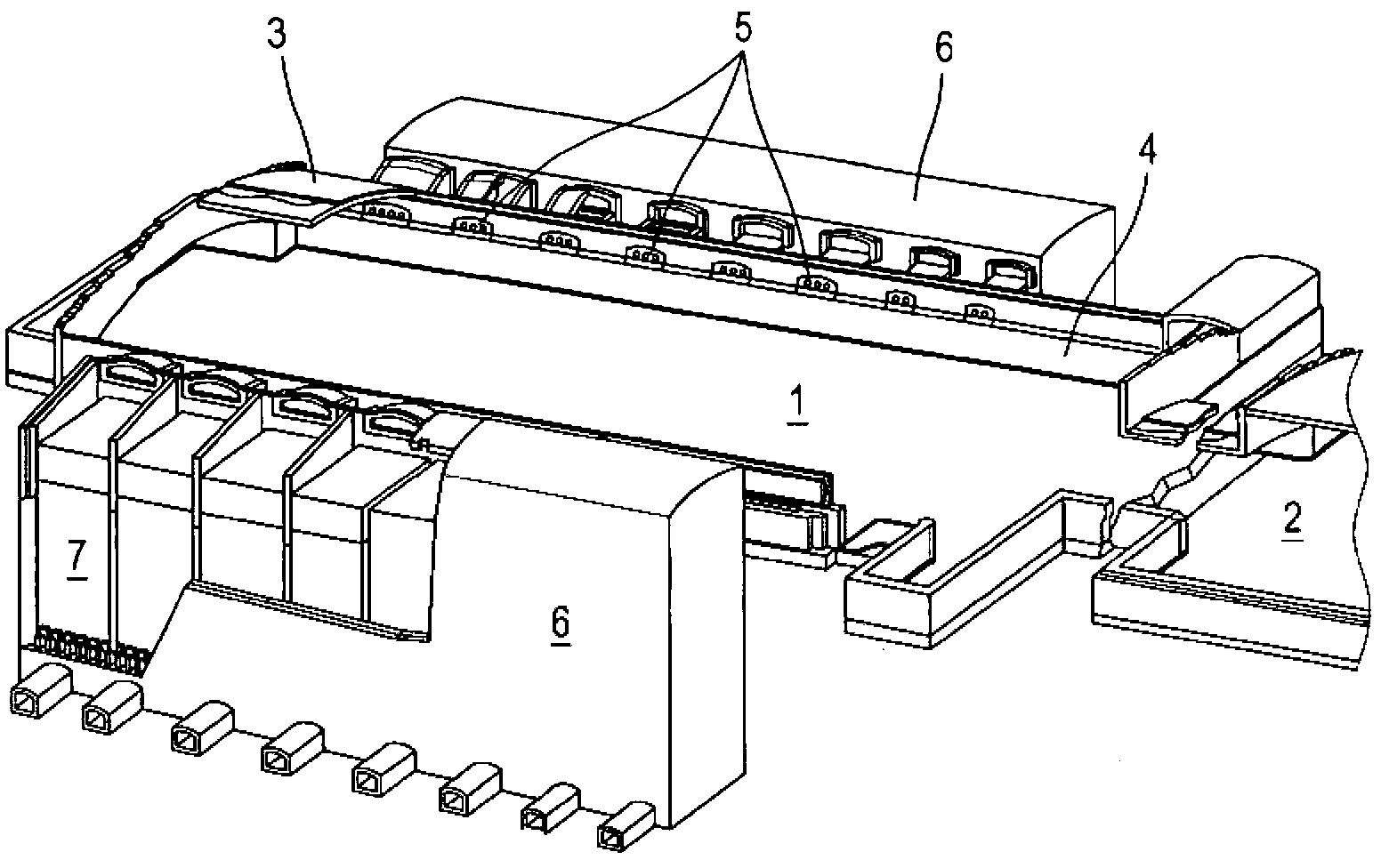

[0035] figure 1 The kiln shown consists of the following main parts: A tank 1 made of refractory material, in which the raw material is injected at the left end. Appears as an empty pool that fills with molten glass at runtime. Glass flows from left to right and communicates with refining tank 2 .

[0036] The pool belongs to a closed whole, the upper part forms the furnace roof, of which only a small part is shown 3 . The side wall body 4 has an opening 5 which communicates with a regenerator lined with refractory material 7 .

[0037] The kiln is constructed in a symmetrical manner with respect to its longitudinal axis. The opening of the wall faces the same opening of the other wall, and each opening communicates with a regenerator.

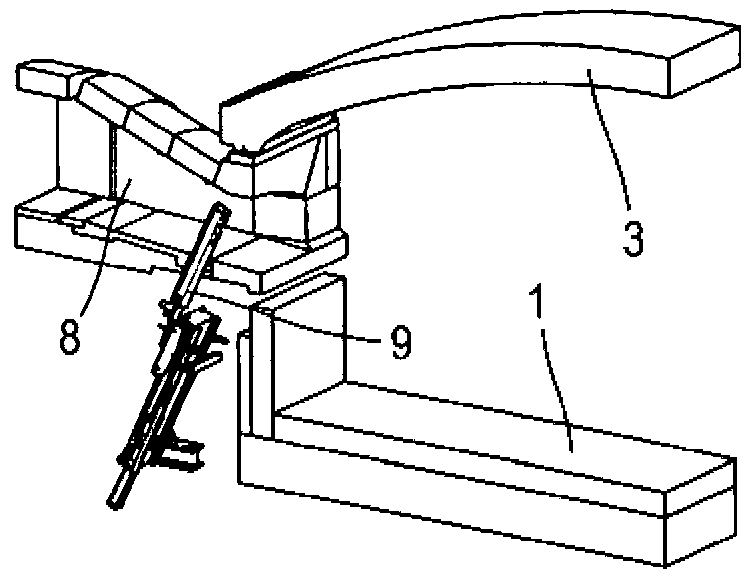

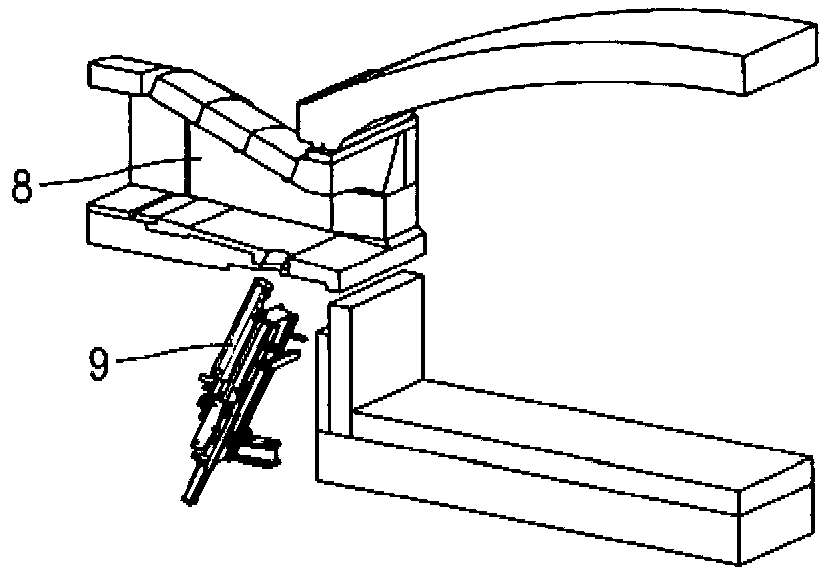

[0038] exist figure 2 with image 3 In the preferred mode according to the invention shown, the burner 9 is arranged in the inlet pipe 8 connecting the regenerator with the opening 5 .

[0039] image 3 The burner 9 is shown in the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com