Multi-crop united screening and sowing machine for wheat, rice, grass and vegetables

A crop and rack technology, applied in the field of tillers, can solve the problems of manual operation, labor-intensive, failure to realize mechanization, etc., and achieve the effect of close distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

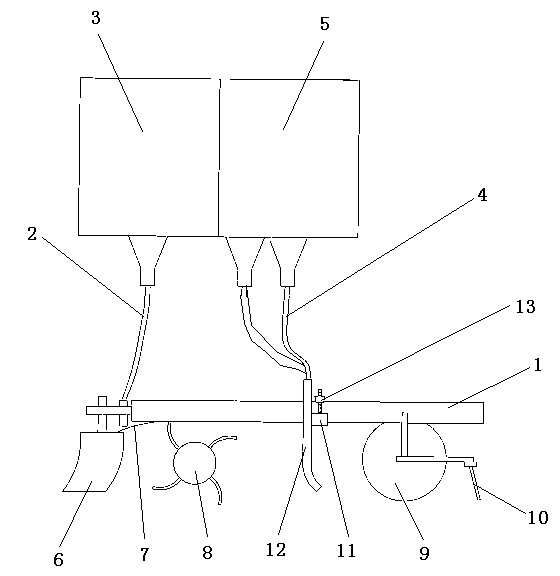

[0012] Below in conjunction with accompanying drawing, the structure of wheat, rice, grass, vegetables multi-crop combined screening machine provided by the present invention is described in further detail.

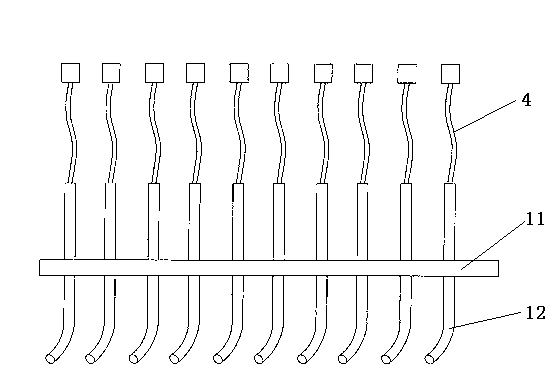

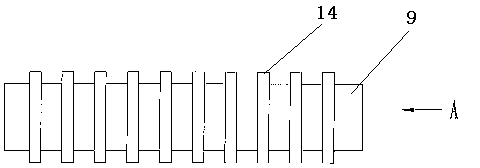

[0013] Such as figure 1 Shown, the present invention wheat, rice, grass, the multi-crop joint screening machine of vegetable comprises frame 1, and frame 1 is provided with fertilizer box 3 with fertilizer pipe 2, seed box 5 with seed pipe 4, Ditching and ridge building device 6, fertilizer uniform plate 7, rotary cultivator knife 8, packer 9 and soil scraping plate 10, seed tube 4 is set with double rows of shafts, frame 1 is provided with grate beam 11, hollow tubular grating teeth The grate type seeder composed of 12, the densely arranged hollow tubular grate teeth 12 are fixed on the grate beam 11, the bottom end of the hollow tubular grate teeth 12 is close to the ground, the upper end of the hollow tubular grate teeth 12 is connected with the seed pipe 4, and the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com