Pre-flotation pretreatment method for fine-particle weathered tungsten ore

A pretreatment and weathering technology, applied in the field of comprehensive utilization of resources, can solve the problems of waste of tungsten resources and low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

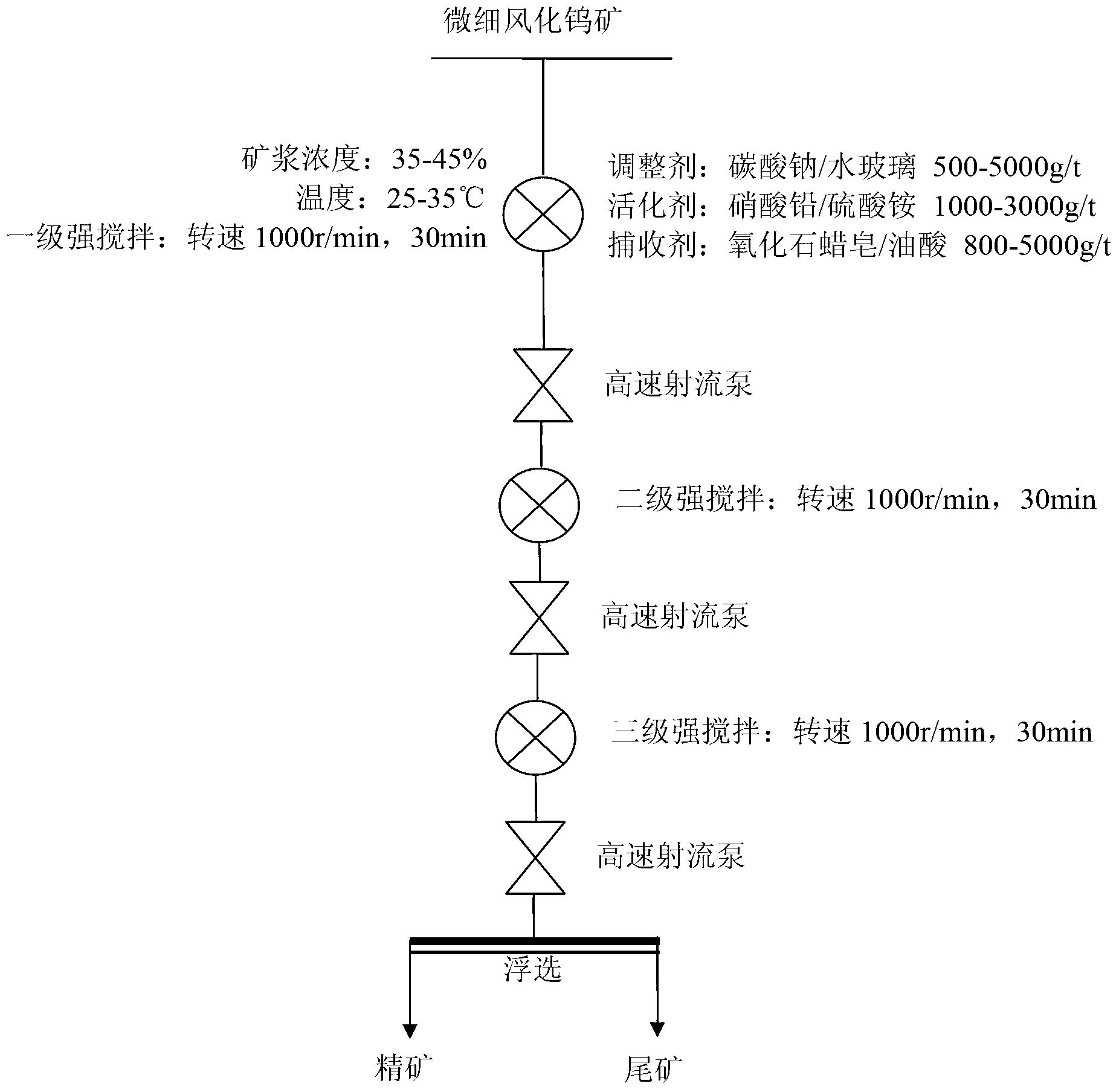

Method used

Image

Examples

Embodiment 1

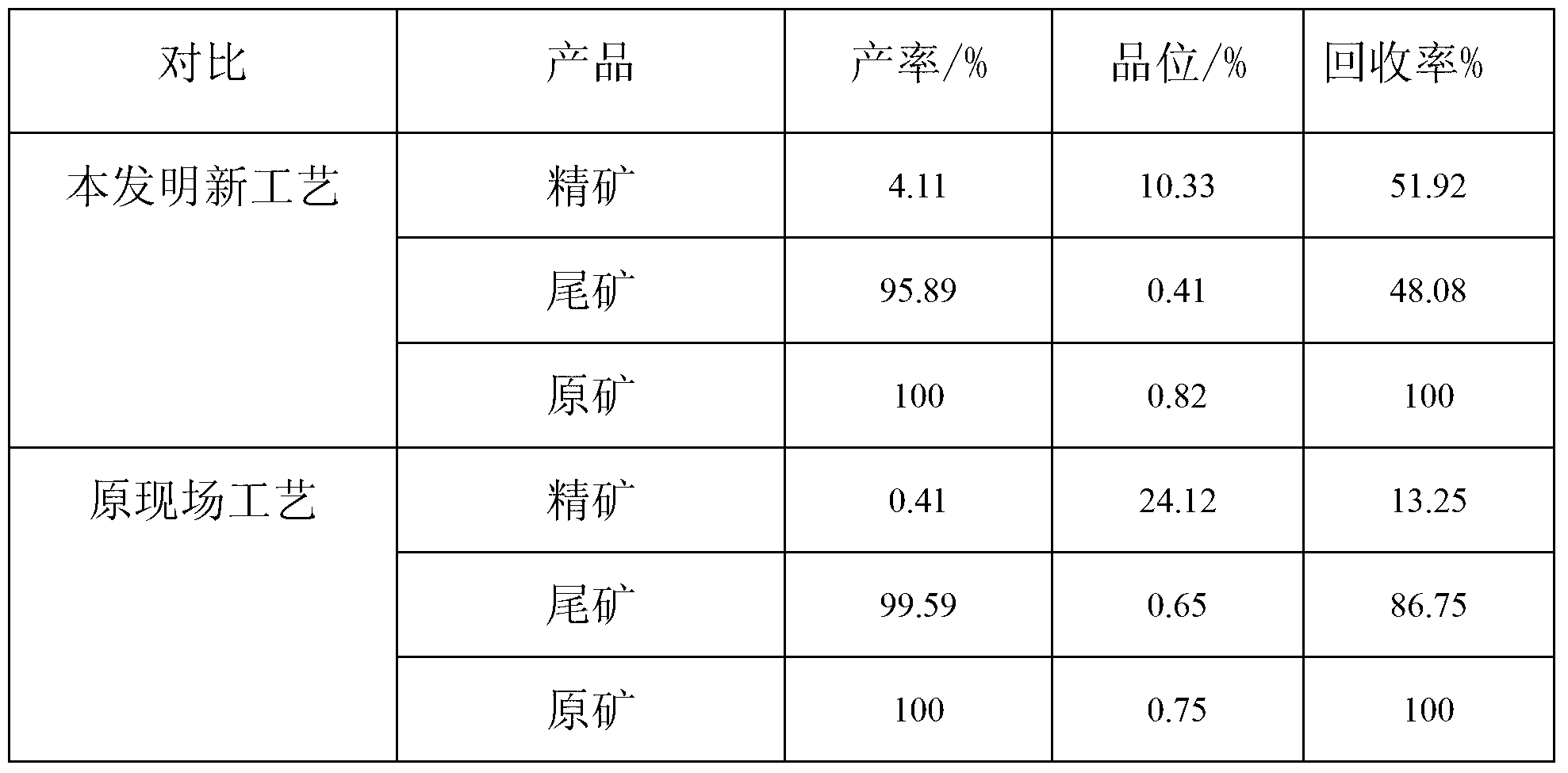

[0014] Using the pretreatment process of the present invention, experiments were carried out on the fine primary overflow produced by the desliming of a tungsten mine in a certain place in Hunan. In the on-site production, due to the large amount of ore slime, if this part of the slime enters the flotation process, the flotation conditions will be greatly deteriorated, so it needs to be washed to remove the sludge. However, a considerable part of the original fine-grained tungsten is taken away during desliming, and the grade of this part of tungsten resources is generally 2-3 times that of the selected grade of the concentrator, generally around 0.8%. Adopt the process method of the present invention, the concentration of ore pulp is controlled at about 40%, add sodium carbonate 2000g / t, lead nitrate 2000g / t, oleic acid 3000g / t respectively, after fully stirring with flotation agent in the primary mixing tank The ore slurry enters the secondary mixing tank through the high-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com