Harmless treatment process of kitchen wastes

A technology for harmless treatment of food waste, applied in the fields of "reduction", "harmless" treatment of food waste, harmless treatment of food waste, and "recycling" can solve energy consumption High, resource waste, difficult process control and other problems, to achieve the effect of increasing soil fertility, good economic and social benefits, and ensuring food hygiene and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

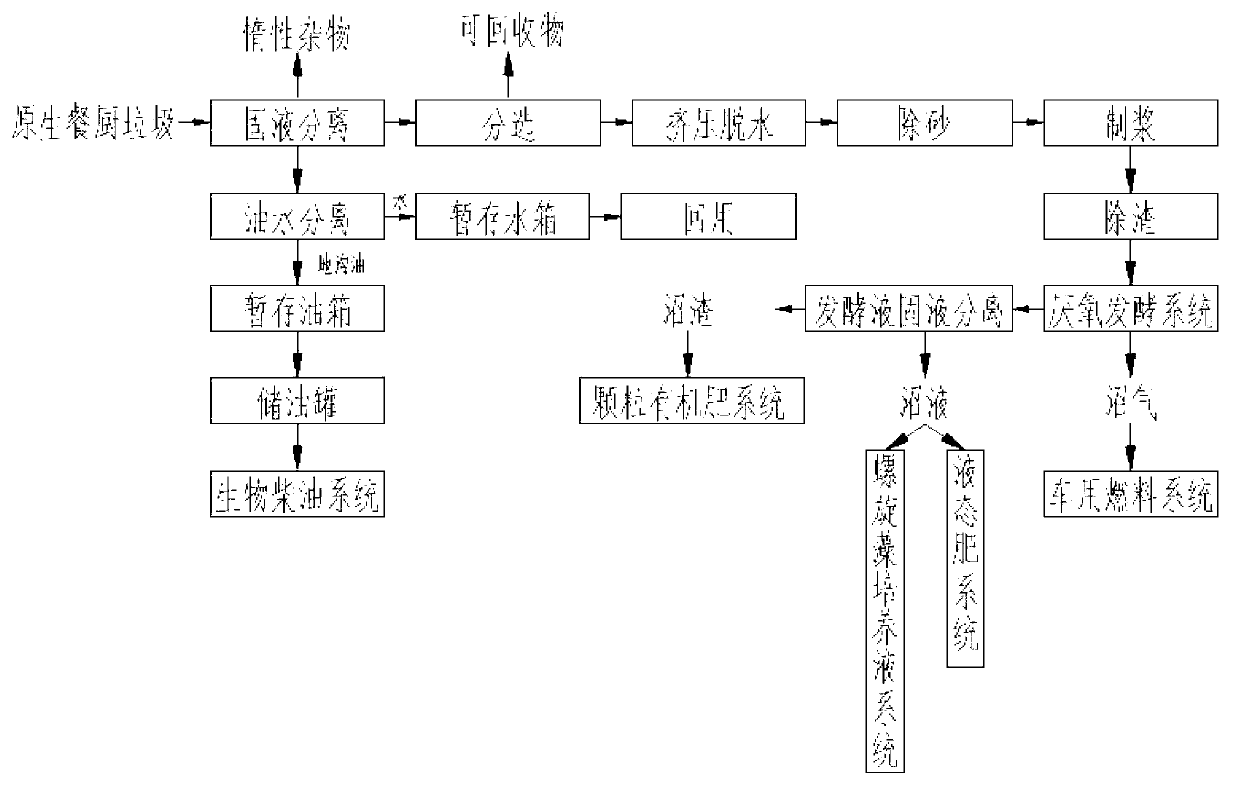

[0018] Take 300 tons of kitchen waste for harmless treatment. The treatment process mainly includes four systems: collection and transportation system, pretreatment system, anaerobic fermentation system, and product utilization. For its process, see figure 1 shown.

[0019] 1. Collection and transportation system

[0020] The 300 tons of food waste collected will be transported to the food waste treatment line by a special garbage transport vehicle. Food waste transport vehicles are purchased according to the ratio of loading capacity of 8 tons: 5 tons: 3 tons = 5: 8: 3.

[0021] 2. The device and process flow of the pretreatment system are as follows:

[0022] The effective volume of the solid-liquid separation type collection box of the pretreatment system is 12m 3 , Steam heating pipes are arranged at the bottom of the box, and the temperature is raised for half an hour to increase the temperature of the material from 10°C to 80°C. The collection box can realize the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com