Acid adding device, as well as method and equipment for producing calcium chloride with acid adding device

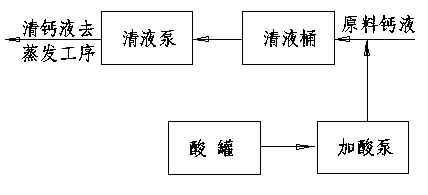

An acid adding device and calcium chloride technology, which is applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problem of scarring of evaporation heaters and affecting products without pretreatment of acid adding device. Quality and other issues, to achieve the effect of prolonging the operation cycle of equipment, good product quality and remarkable energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

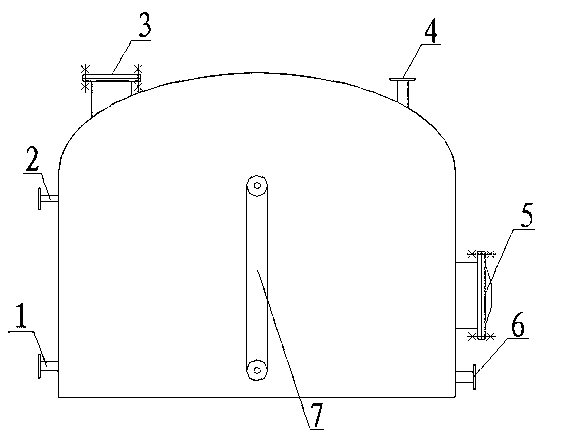

[0024] A kind of acid adding device, see attached figure 1 As shown in the figure: hydrochloric acid outlet 1, hydrochloric acid inlet 2, cleaning port 3, spare port 4, manhole 5, drain port 6, liquid level gauge 7.

[0025] The acid tank is provided with a hydrochloric acid inlet 1, a hydrochloric acid outlet 2, a cleaning port 3, a cleaning port 6, a spare port 4 and a manhole 5, and the spare port 4 is placed on the top of the acid tank.

[0026] The hydrochloric acid inlet 2 and the hydrochloric acid outlet 1 are arranged on the same side of the acid tank, the cleaning port 3 is placed on the top of the acid tank, and the cleaning port 6 is placed on the bottom of the acid tank.

[0027] The acid tank is equipped with a liquid level gauge 7; the manhole 5 is placed in the middle of the acid tank. The acid adding device has a simple structure, and the impur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com