Anti-static fuel additive and preparation method thereof

An antistatic and additive technology, applied in the field of fuel antistatic additive and its preparation, can solve the problems of reducing the conductivity of the antistatic additive, fast decay of the conductivity of the fuel oil, decay of the conductivity, etc. Good stability and stable conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of polyaminosulfone

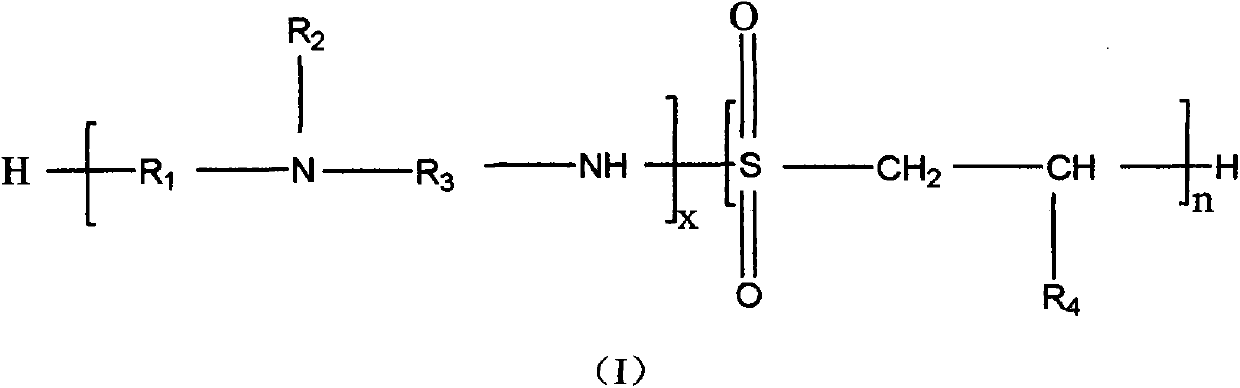

[0044]

[0045] Wherein, x is selected from an integer of 80-120, and n is selected from an integer of 80-100.

[0046] Its preparation method is:

[0047]

[0048] The preparation method of polyamino sulfone is as follows: polysulfone is first added to the reaction kettle, and toluene is added in proportion, and the volume ratio of polysulfone and toluene is 20:1; after stirring for 2 hours, add NaOH solid flaky particles; heat up to 90°C; under the protection of nitrogen, add polyamine in batches in proportion while stirring, the molar ratio of polysulfone and polyamine is 1:1, polyamine is added in 10 batches, and the proportion of polyamine added each time is 10%; stirred for 7 hours, and the stirring speed was 120 revs / min; after cooling, the reaction was completed; settled for 48 hours with a settling tank; after the unreacted NaOH flaky particles settled to the bottom of the container, the clear liquid after the transfe...

Embodiment 2~3

[0053] 1. Preparation of polyaminosulfone

[0054]

[0055] Each substituent in its molecular formula is as shown in table 1:

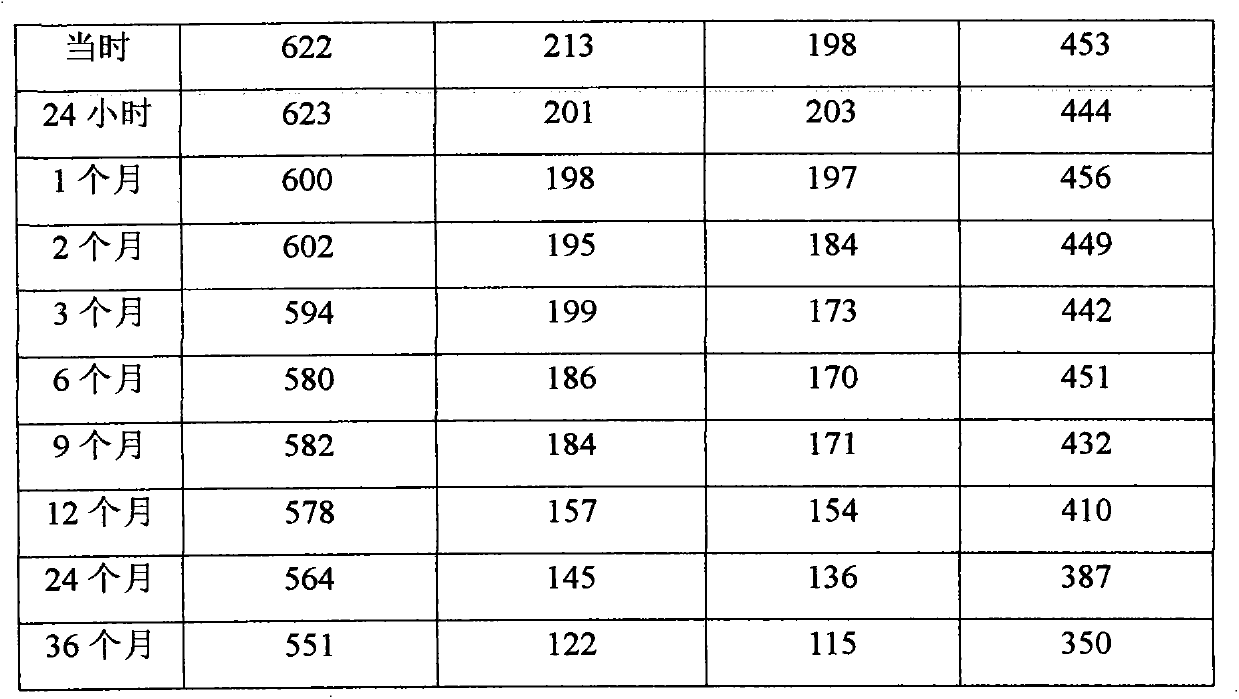

[0056] Table 1:

[0057]

[0058] The preparation method is as follows: first add polysulfone into the reaction kettle, then add xylene in proportion, the volume ratio of polysulfone and xylene is 10:1; after stirring for 15 minutes, add NaOH solid flaky particles; heat up to 60°C, Under the protection of nitrogen, add polyamine in batches while stirring, the molar ratio of polysulfone and polyamine is 1:1, polyamine is added in 5 batches, and the ratio of adding polyamine each time is 20% of the total amount of polyamine Stirring 5 hours, stirring speed is 180 rev / mins; After cooling, reaction is completed; Settled 72 hours with settling tank; After the unreacted NaOH solid flaky particles settled to the bottom of the container, the clear liquid after the transfer settling obtained such as formula ( I) The polyaminosulfone shown.

[0059] 2...

Embodiment 4~5

[0063] 1. Preparation of polyaminosulfone

[0064]

[0065] Each substituent in its molecular formula is as shown in table 2:

[0066] Table 2:

[0067]

[0068] The preparation method is as follows: first add polysulfone into the reaction kettle, then add ethylbenzene in proportion, the volume ratio of polysulfone and ethylbenzene is 25:1, after stirring for 1 hour, add NaOH solid flaky particles; heat up to 65°C; Under nitrogen protection, add polyamine in proportion while stirring, and add in 2 batches. The proportion of polyamine added each time is 50% of the total amount of polyamine; stir for 10 hours, and the stirring speed is 60 rpm; after cooling, the reaction is completed 36 hours with settling tank sedimentation; After the NaOH solid settled to the bottom of the container, transfer the clear liquid after the settlement to obtain the polyaminosulfone as shown in formula (I).

[0069] 2. Preparation of fuel antistatic additives:

[0070] Prescription: contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com