Preparation method of novel film-coated needle tip for needle tip enhanced Raman measurement

A needle-tip enhanced Raman and needle-tip technology, which is applied in the directions of Raman scattering, sputtering plating, ion implantation plating, etc., can solve the problems of lack of repeatability, low yield of needle tip, and difficulty in maintaining repeatability of the enhancement effect, etc. Achieve obvious enhancement effect, stable enhancement coefficient and stable grain shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a novel coated needle tip for tip-enhanced Raman measurement, specifically comprising the following steps:

[0022] As shown in Fig. 2(b), step (1) utilizes the focused ion beam (FIB) technique to process a circular cone hole on the tip of the silicon needle. The diameter of the circular cone hole is 90-110 nm and the depth is 60 nm. ~80nm;

[0023] As shown in Figure 2 (a), the step (2) circular cone coating, specifically, the silver particles in the circular cone hole on the needle tip and grow up; the circular cone hole can play a role in the growth of silver particles. Effective restraint;

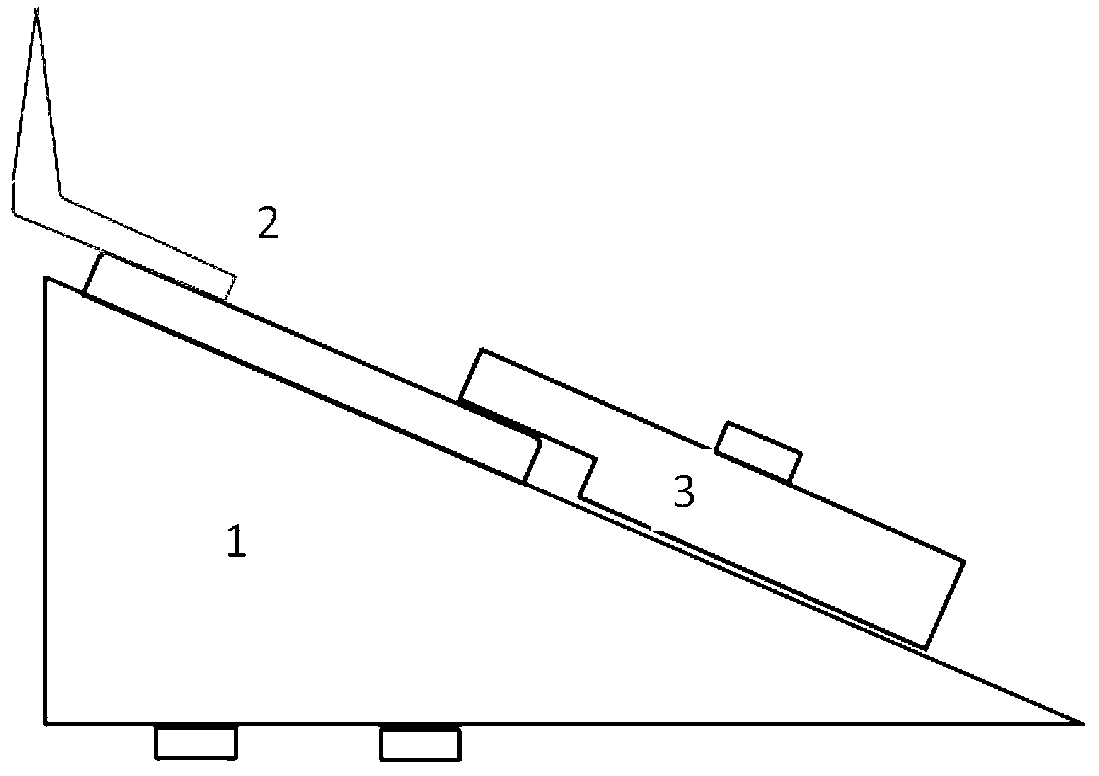

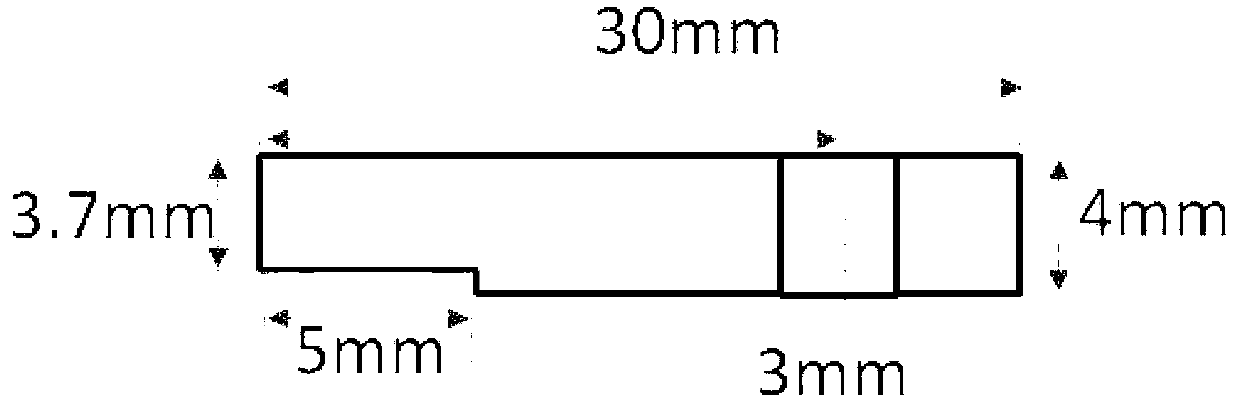

[0024] Such as Figure 1(a) , 1(b) , shown in 1 (c), step (3) fixes the needle point on the novel needle point fixture, and described novel needle point fixture comprises the lower cover plate 1 of the needle point frame, the upper cover plate 3 of the needle point frame; the cross section of the needle point frame lower cover plate 1 is Right-angled t...

Embodiment

[0028] Step (1) Use focused ion beam technology (FIB) to process a circular cone hole on the tip of the silicon needle. The diameter of the circular cone hole is 100 nm and the depth is 70 nm;

[0029] Step (2) Coating the circular cone hole, specifically, the silver particles are cored and grown in the circular cone hole on the needle tip; the circular cone hole can effectively restrain the growth of the silver particles;

[0030] Step (3) fix the needle point on the novel needle point fixture, the novel needle point fixture comprises the needle point frame lower cover plate 1, the needle point frame upper cover plate 3; The inclined surface of the lower cover plate 1 of the needle point frame; the upper cover plate 3 of the needle point frame has a rectangular cross-section, and one end of its lower surface has a through groove, and the front of the needle point is connected with the lower surface through groove of the upper cover plate 3 of the needle point frame; The lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com