Preparation method of catalyst for synthesizing allyl acetate

A technology of allyl acetate and catalyst, which is applied in the field of preparation of catalysts for the synthesis of allyl acetate, can solve the problems of low space-time yield and selectivity, and achieve improved space-time yield and selectivity, good dispersibility, The effect of good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) Catalyst preparation

[0016] Step (a): Take 1200ml of an aqueous solution containing chloropalladium acid and copper chloride as the impregnation solution, wherein the palladium content in the solution is 2.75g / L, the copper content is 0.625 g / L, and impregnate 1100ml of 4~6mm in diameter Spherical silica carrier obtains catalyst precursor I;

[0017] Step (b): 27.5 g of sodium silicate nonahydrate was formulated into 100 ml of aqueous solution and added to the catalyst precursor I, mixed uniformly, left standing for 24 hours, and then dried at 80 ° C for 8 hours to prepare the catalyst precursor II;

[0018] Step (c): Take 100ml of an aqueous solution containing polyvinylpyrrolidone (weight-average molecular weight: 360,000), wherein the content of polyvinylpyrrolidone is 100g / L, impregnate catalyst precursor II to prepare catalyst precursor III;

[0019] Step (d): reducing the catalyst precursor III in a hydrogen atmosphere, the hydrogen flow rate is 0.2 ml / min,...

Embodiment 2

[0033] [Example 2] to [Example 11]

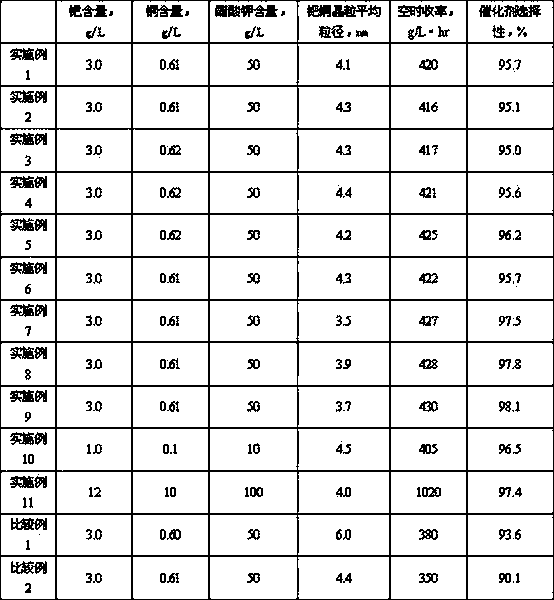

[0034] In addition to the type of palladium-containing compound and copper-containing compound, the content of palladium-containing compound and copper-containing compound, the type of stabilizer, the concentration of the stabilizer, the weight-average molecular weight of the stabilizer, the weight ratio of the stabilizer, the type of reducing agent and reducing Except temperature has change, other steps are all identical with embodiment 1. For the convenience of comparison, the preparation conditions of the catalyst are listed in Table 1, and the physical properties of the catalyst and the space-time yield and selectivity data of the catalyst are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com