Magnetic nanowire array thin film and preparation method thereof

A magnetic nanometer and line array technology, applied in ion implantation plating, metal material coating process, coating, etc., to meet the needs of different operating frequencies, simple operation, and good insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

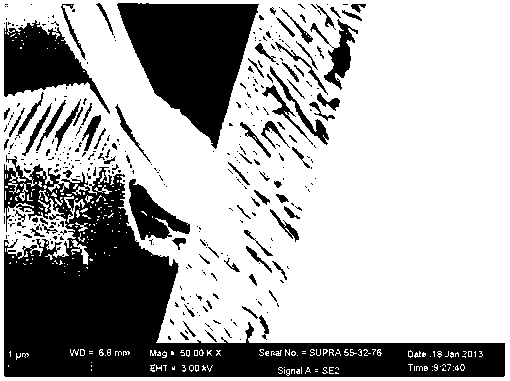

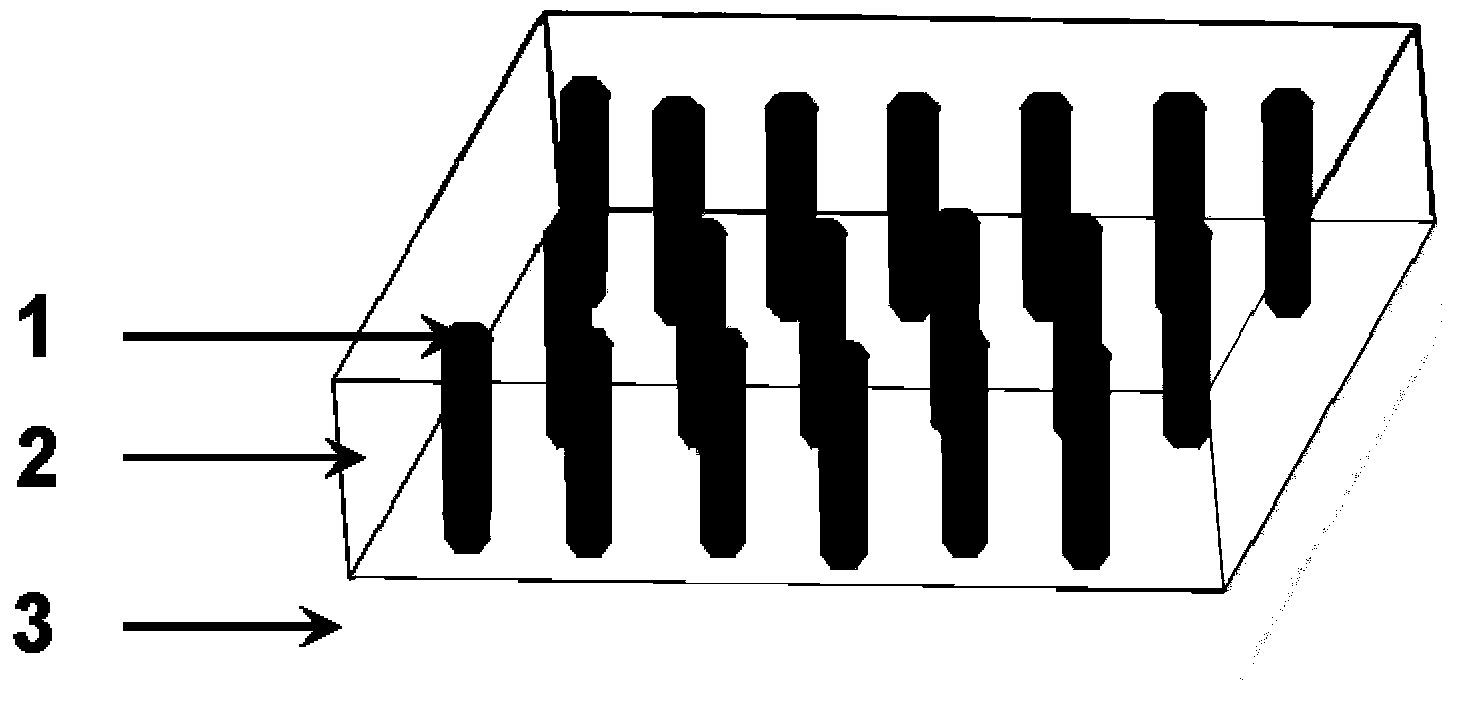

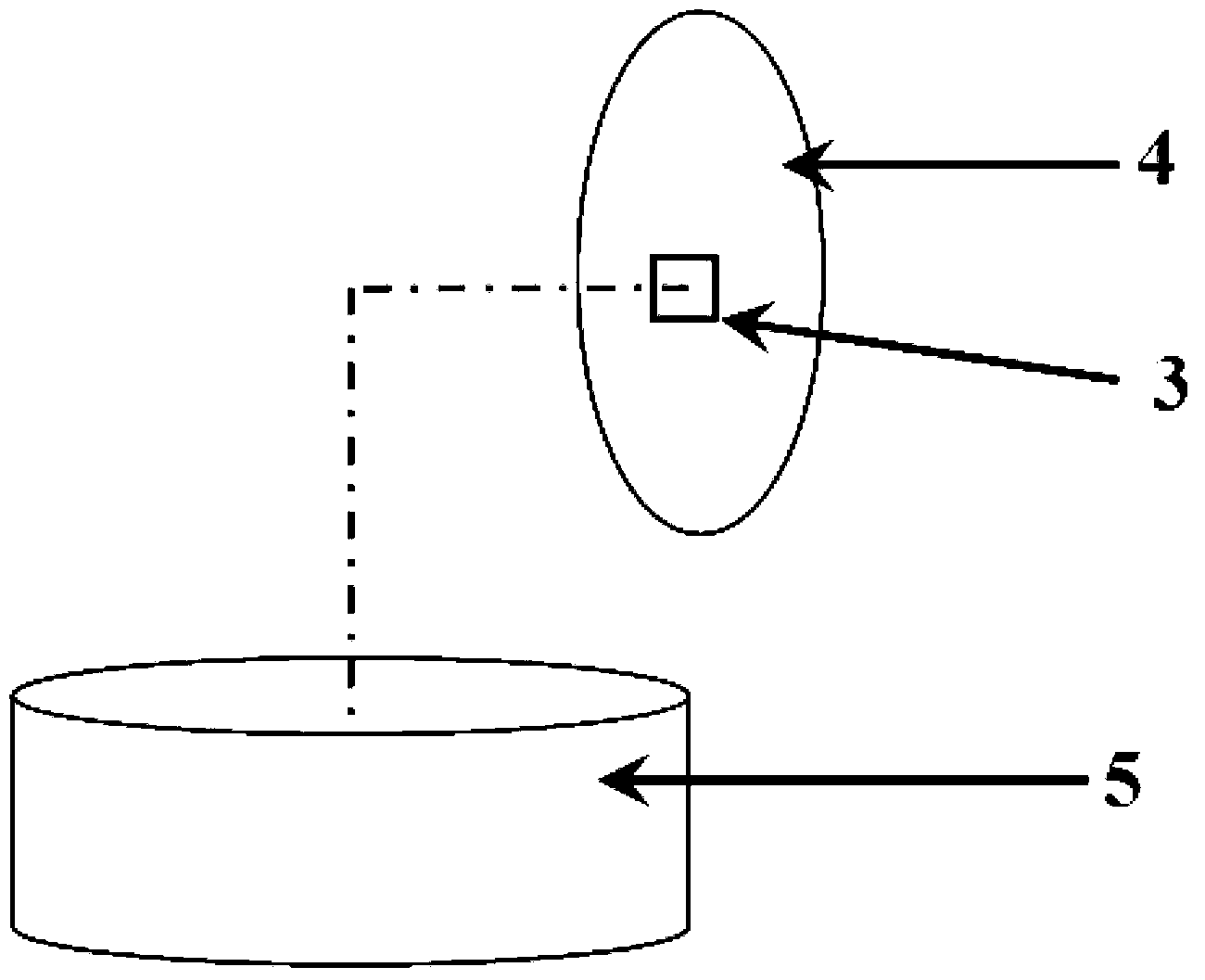

[0035] A magnetic nanowire array thin film, such as figure 1 shown, including MgAl 2 o 4 (MAO) single crystal substrate 3, Pb(Zr 0.52 Ti 0.48 )O 3 (PZT) matrix 2 and NiFe 2 o 4 (NFO) nanowires1. Among them, the MgAl 2 o 4 (MAO) single crystal substrate 3 is (001) oriented and surface polished MgAl 2 o 4 single crystal substrate; the NiFe 2 o 4 The nanowires 1 are uniformly distributed in Pb(Zr 0.52 Ti 0.48 )O 3 In the substrate 2, a magnetic nanowire array film is formed; the magnetic nanowire array film is deposited on the MgAl 2 o 4 (MAO) on the (001) oriented surface of the single crystal substrate 3 .

[0036] Further, the NiFe 2 o 4 The diameter of the nanowire 1 is between 70nm and 250nm, and the length is between tens of nanometers and several microns.

[0037] In the magnetic nanowire array thin film provided by the invention, the PZT substrate has high insulation and piezoelectricity at the same time, and the NFO nanostructure has high insulation, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com