Method for plugging diversion tunnel by cast-in-situ reinforced concrete without cutoff by gate and plugging reinforcing cage

A technology of reinforced concrete seal and reinforced cage, which is applied in water conservancy projects, hydroelectric power stations, hydroelectric power generation, etc., can solve the problems of insufficiency, poor quality of diversion tunnel gate piers, catastrophic and other problems, and achieves cost saving, construction Convenience and high quality construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

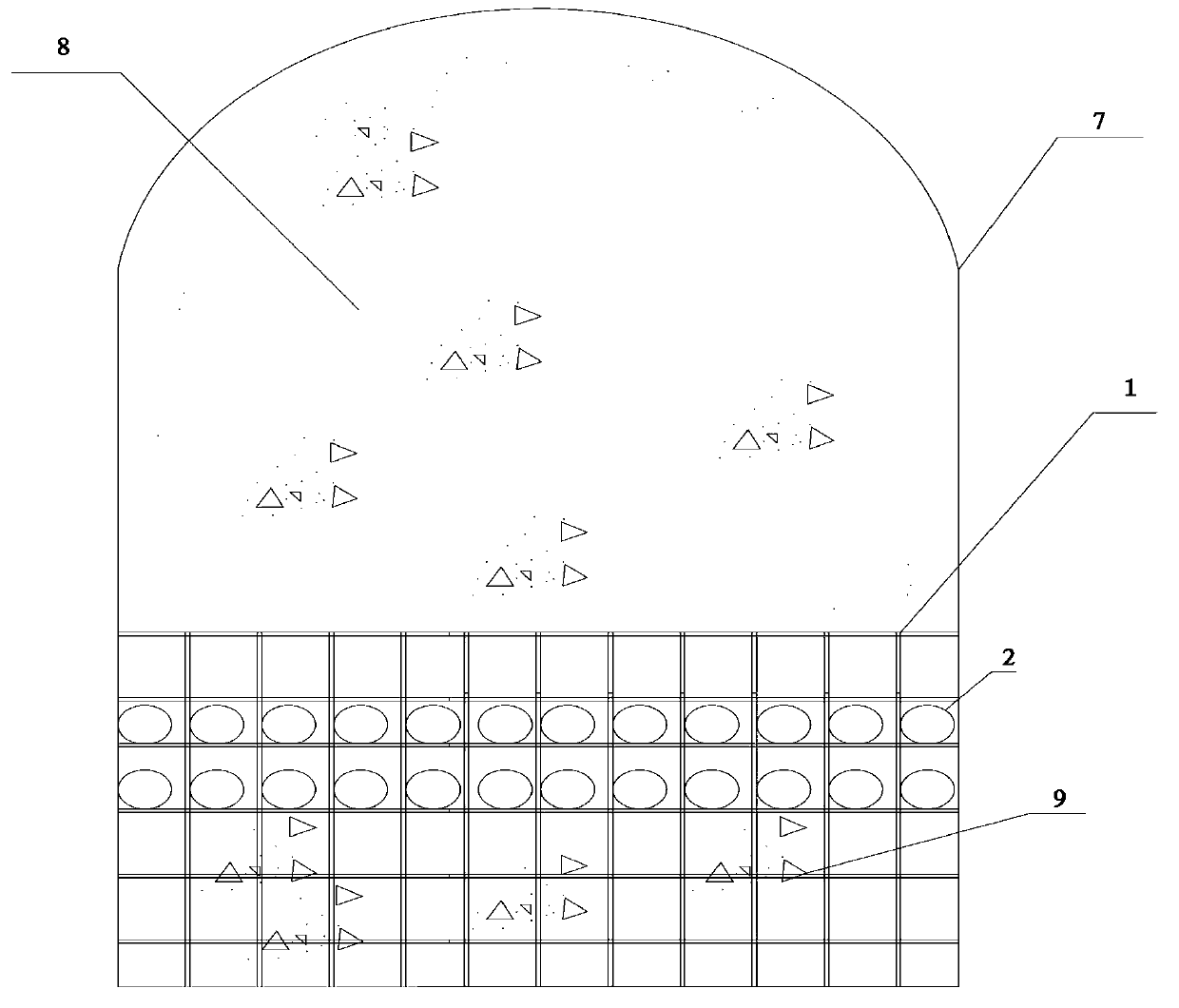

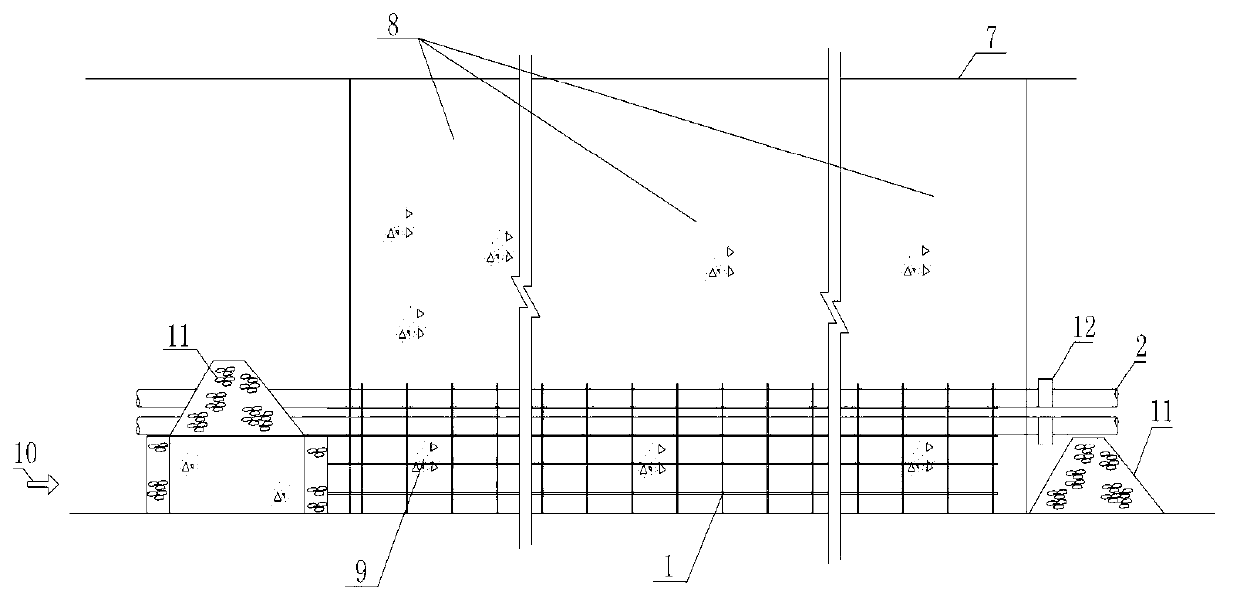

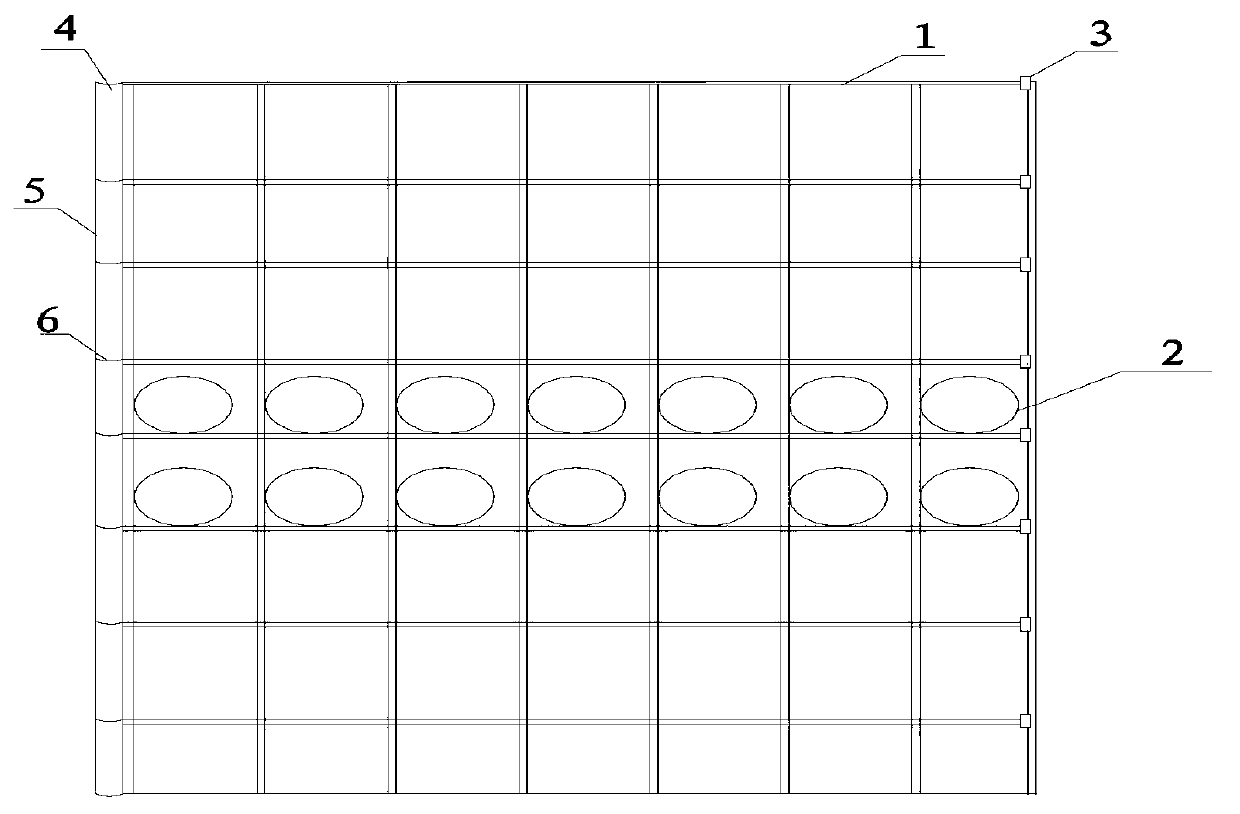

[0055] like figure 1 , figure 2 As shown, a method of plugging diversion tunnels with cast-in-place reinforced concrete without gate cut-off includes the following steps:

[0056] 1) Make two reinforcement cages on the shore, the longitudinal reinforcement length of the reinforcement cages of the two reinforcement cages is 9m (1.2 times of the height of the diversion tunnel 7.5m), and the length of the transverse reinforcement is 2.5m of the diversion tunnel width (the width of the diversion tunnel 1 / 2 of 5m), the height is 3m, which is 1.5 times of the water flow height of the diversion tunnel in the same period, and N / 2 (the specific steps for N below) are inserted into the two steel cages to make it. Block the reinforcement cage, the two ends of the drainage pipe are 1m longer than the reinforcement cage skeleton, and a gate valve is installed at one end of the drainage pipe. Number the plugged reinforcement cages in turn from side to right, and the numbering sequence is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com