Oilfield sewage waste heat recycle and reclaimed water reuse method and device

A technology for oilfield sewage and waste heat recovery, applied in heating water/sewage treatment, preheating, supplementary water supply, etc. The effect of saving energy, reliable principle and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

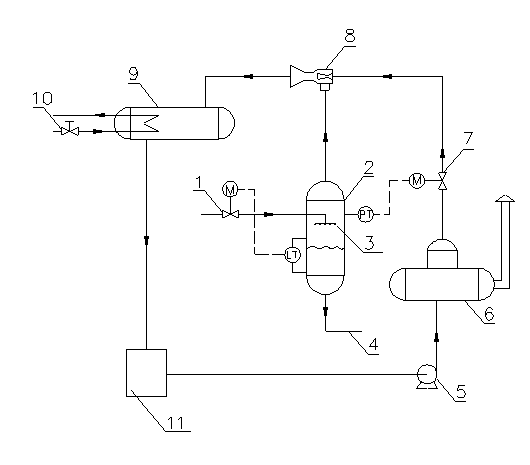

[0019] Implementation case: Taking 2000kW oilfield sewage waste heat recovery heat pump boiler combined system as an example, 90℃ oilfield sewage enters the flash tank for flash evaporation, the flow rate is 12409kg / h, and the working pressure of the flash tower is 0.02MPaa (that is, the pressure of the venturi tube injection port) , the steam pressure at the inlet of the Venturi tube is 1MPa, the flow rate is 2412kg / h, the state is wet and saturated, and the mixed outlet pressure of the Venturi tube is 0.1MPaa. The amount of flash steam is 661kg / h, and the flash evaporation rate of sewage is about 5.33%. The concentrated sewage discharged from the bottom of the flash tank is 11747kg / h and enters the sewage tank. The ejection coefficient of the Venturi tube can reach 0.274, and the heating coefficient of the system is 1.26.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com