Coil winding, combined winding and permanent magnet motor without groove and framework

A coil winding and combined technology, which is applied in the field of coil winding, combined winding and slotless and frameless permanent magnet motors, can solve the problem of high efficiency, motor slot full rate and power density reduction that cannot be achieved for slotless brushless permanent magnet motors , the internal space of the large motor, etc., to achieve the effect of simple and efficient production process, improving the slot full rate and power density, and sufficient space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment:

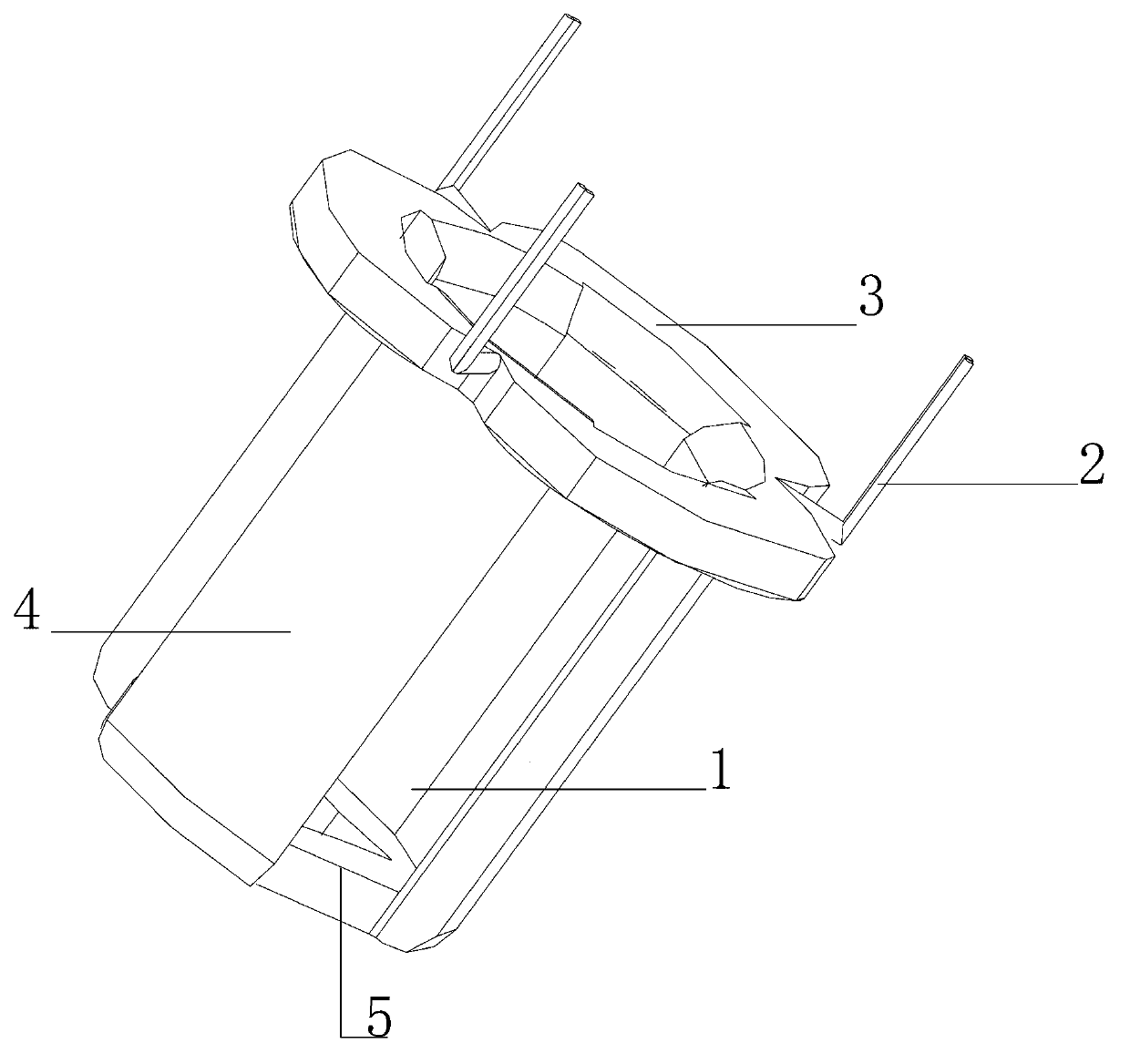

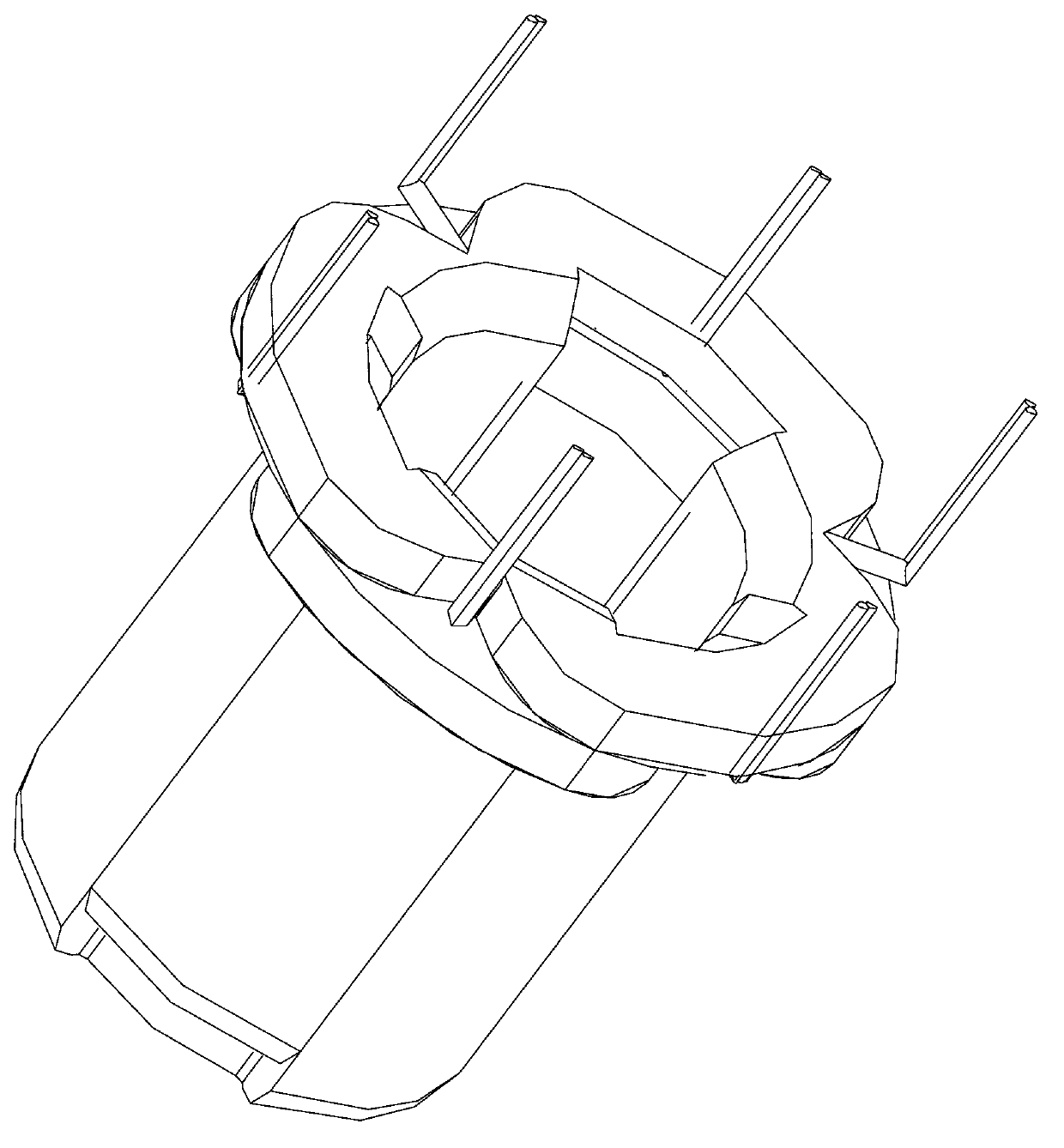

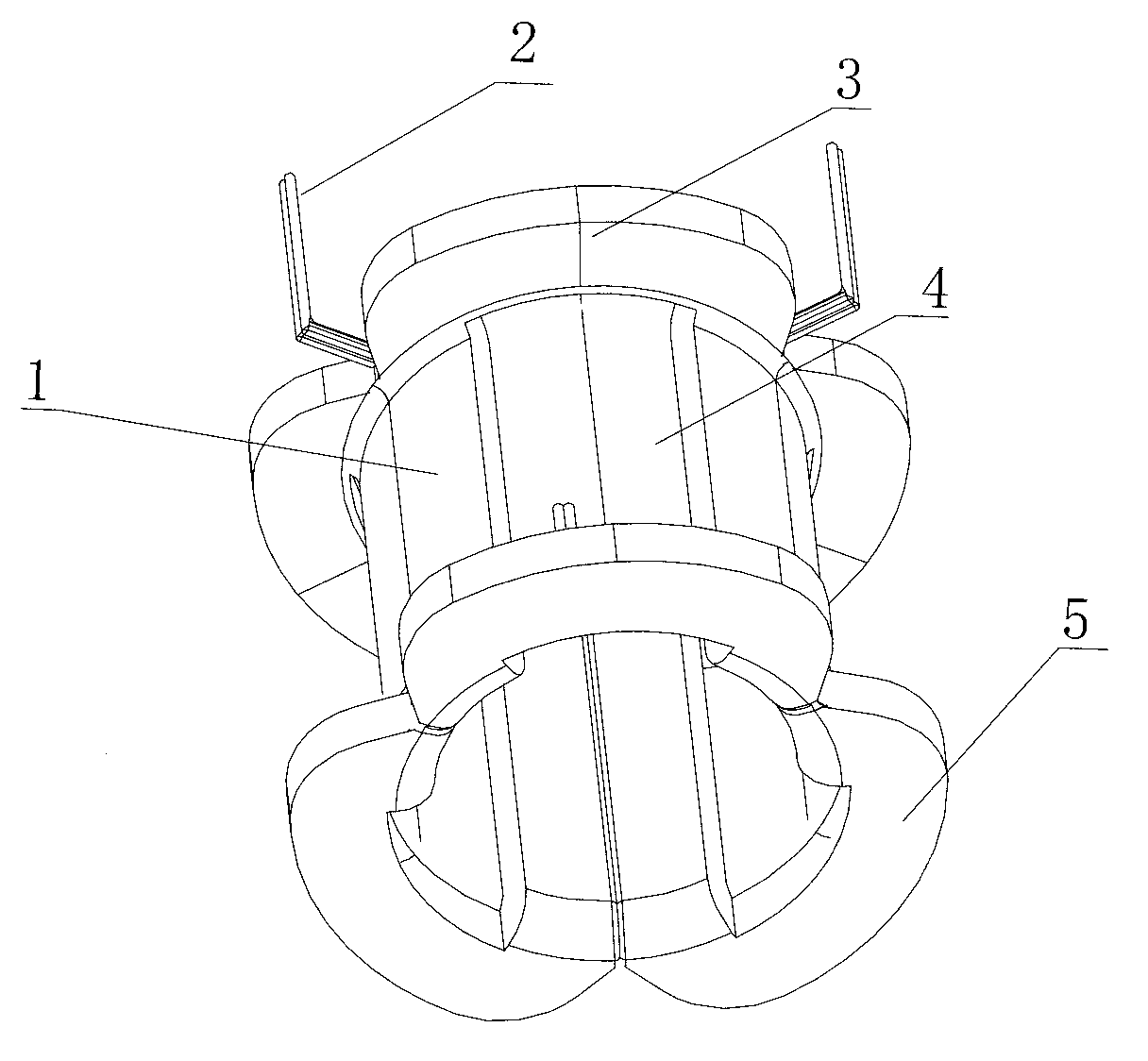

[0044] Such as Figure 1-4 as shown,

[0045] (1) One case: a combined winding formed by nesting two 11-type coil windings

[0046] (2) Another case: a combined winding formed by nesting of 1 type I coil winding and 1 type 11 coil winding

[0047] The I-type coil winding and the coil II-type coil winding consist of the same number of multiple coils, and each coil has the same wire diameter and number of turns.

[0048] The two winding coils are wound on a high-speed winding machine at one time with the same winding frame and self-adhesive enameled wire. (The skeleton does not stay in the winding, it can be reused)

[0049] The winding frame adopts a detachable structure during the winding forming process, and the forming tooling is used together, and the self-adhesive characteristics of the enameled wire can be used to easily and simply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com