Process for producing ethanol and ethylene via fermentation

A self-produced ethanol Clostridium and ethanol technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problems of increasing factory costs and paying emission taxes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0109] Materials and methods:

[0110]

[0111] Preparation of Cr(II) solution: A 1 L three-necked flask was fitted with gas-tight inlet and outlet so that it could be operated under inert gas and the desired product was subsequently transferred to a suitable storage flask. Add CrCl to the flask 3 ·6H 2 O (40 g, 0.15 mol), zinc particles [20 mesh] (18.3 g, 0.28 mol), mercury (13.55 g, 1 mL, 0.0676 mol) and 500 mL of distilled water. use N 2 After rinsing for one hour, the mixture was warmed to about 80°C to initiate the reaction. at constant N 2 Stirred under flow for 2 hours, then cooled the mixture to room temperature and continued to stir for 48 hours, by which time the reaction mixture had turned into a dark blue solution. Transfer the solution to N 2 Rinse the serum bottle and store in the refrigerator until use.

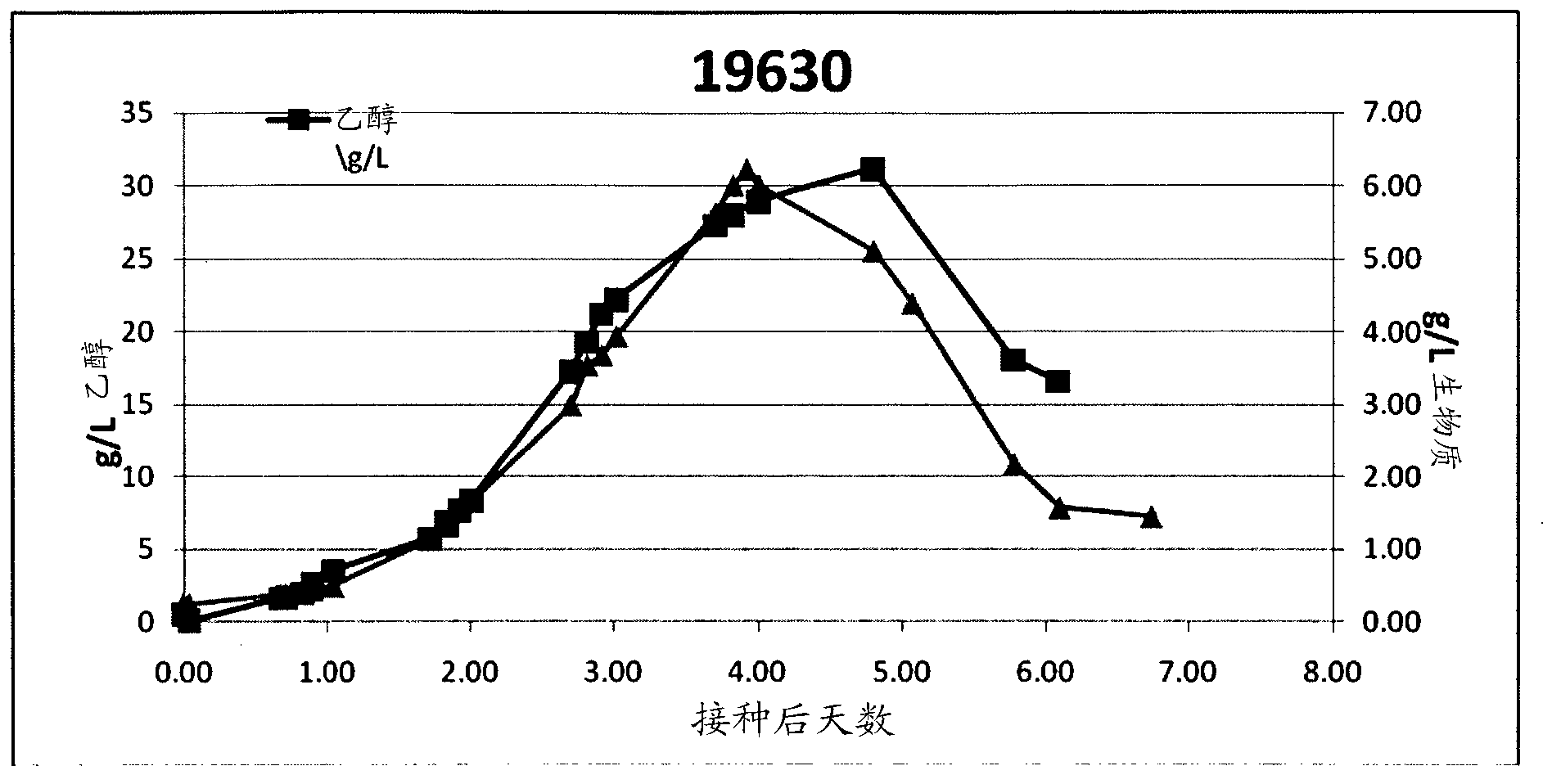

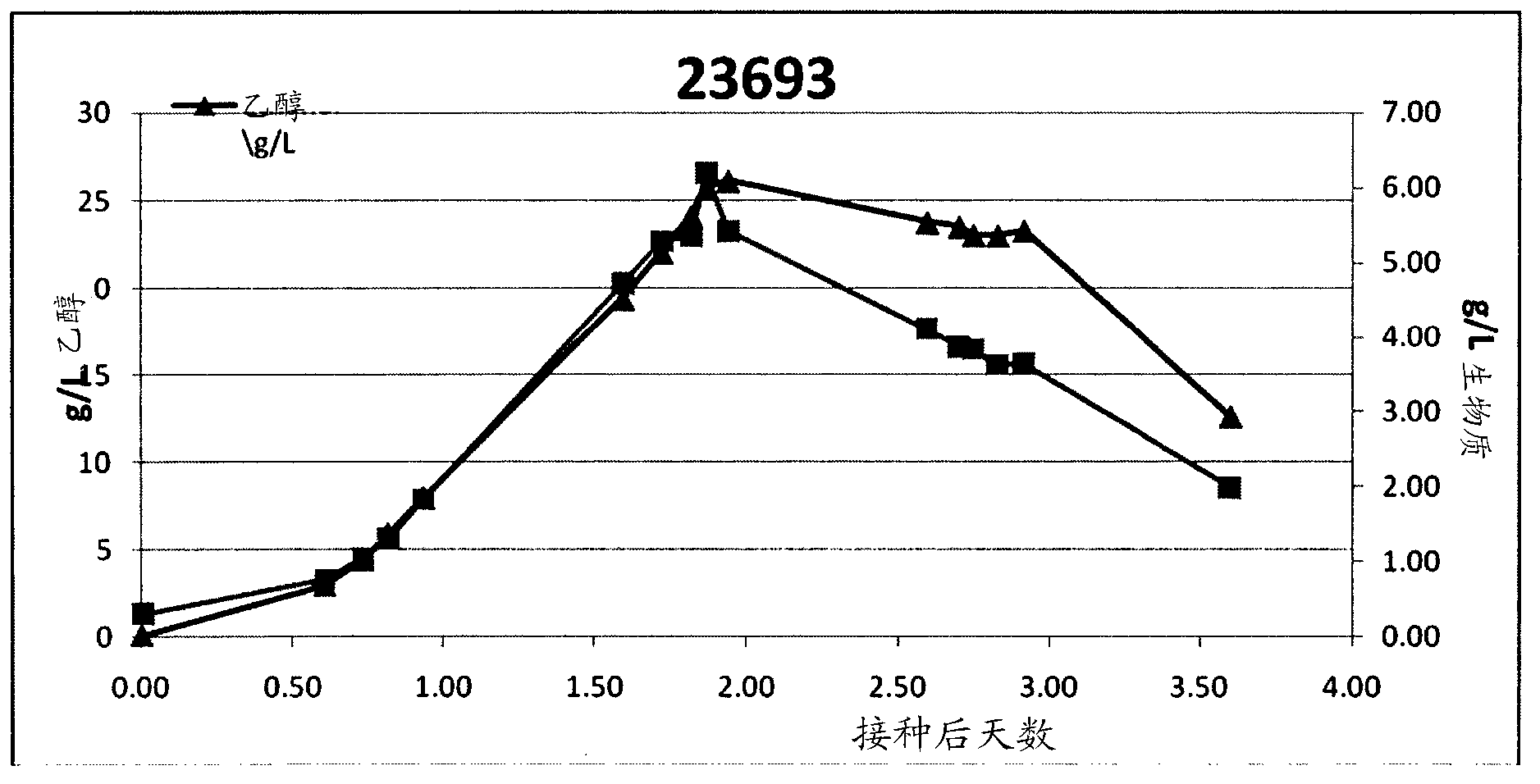

[0112] Bacteria: Two types of Clostridium autoethanogenum were used in the following examples.

[0113] Both DSM19630 and DSM23693 were deposited at...

Embodiment 2

[0126] Materials and methods:

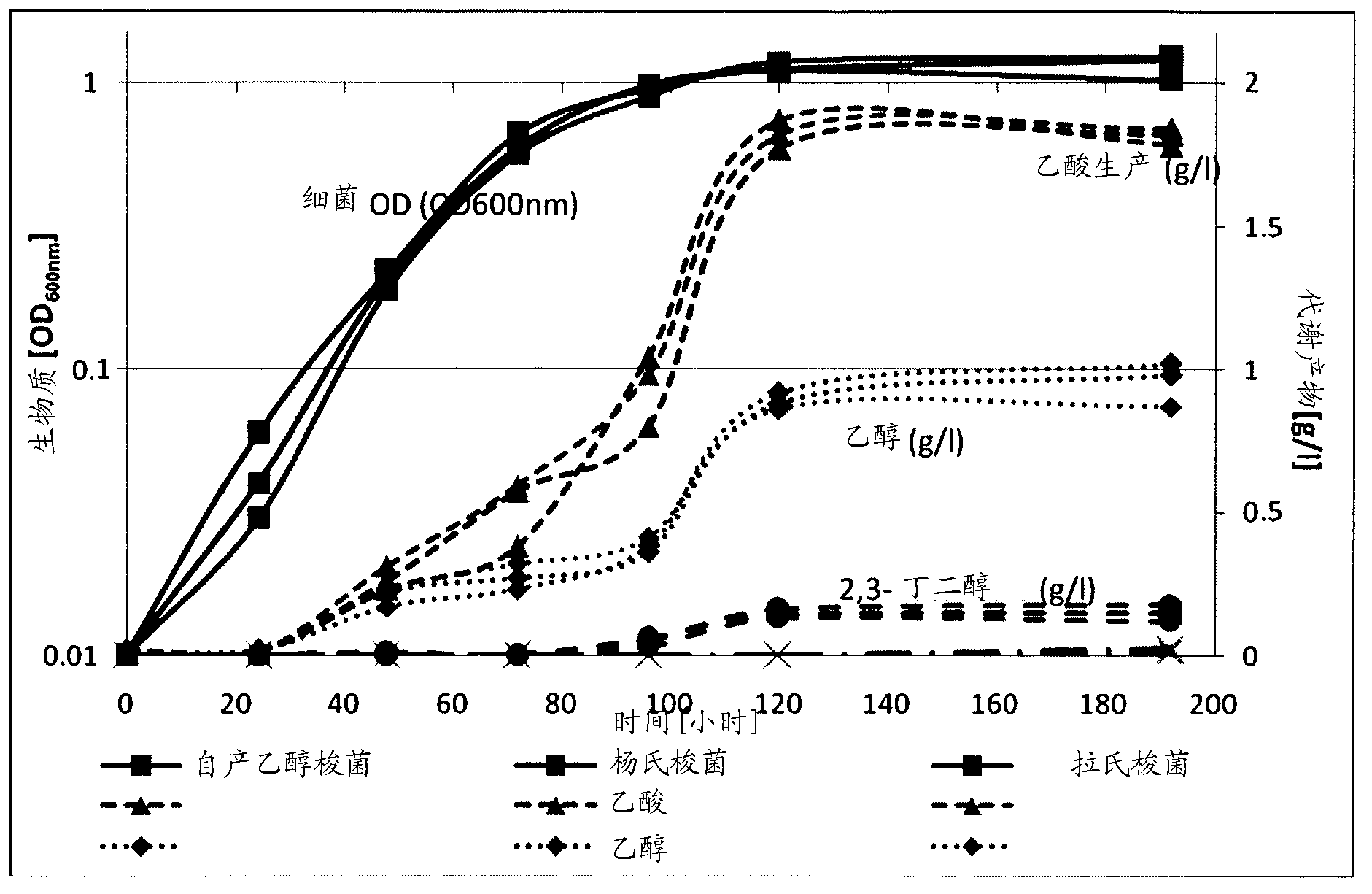

[0127] Bacterial strains and growth conditions: Clostridium autoethanogenum DSM10061 and Clostridium ljungdahlii DSM13582 were obtained from DSMZ (Deutsche Sammlung von Mikroorganismen und Zellkulturen GmbH), Clostridium rasseri ATCC-BAA622 TM Obtained from ATCC (American Type Culture Collection). All organisms were grown anaerobically in modified PETC medium (ATCC medium 1754) at 30 °C (C. lasseri) or at 37 °C (C. autoethanogenum and C. ljungdahlii), respectively.

[0128] The improved PETC medium (per L) includes 1g NH Cl, 0.4g KCl, 0.2g MgSO 4 ·7H 2 O, 0.8g NaCl, 0.1g KH 2 PO 4 , 20mg CaCl 2 2H 2 O, 10ml trace element solution (see below), 10ml Wolfe's vitamin solution (see below), 2g NaHCO 3 and 1 mg resazurin. After adjusting the pH to 5.6, the medium was anaerobically boiled, dispensed, and autoclaved at 121° C. for 15 minutes. Steel mill exhaust gas (composition: 44% CO, 32% N) collected from the New Zealand steel site in Glenbrook...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com