Sweet potato leaf and stem green juice powder beverage and preparation method thereof

A sweet potato leaf and powder technology, applied in the field of sweet potato leaf and stem green juice powder beverage and its preparation, can solve the problems of inconvenient storage and transportation, easy loss of nutrition and functional components, etc., and achieve convenient storage and transportation, good comprehensive palatability, Lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Raw materials: fresh Simon No. 1 sweet potato leaves and stems are used as raw materials for processing;

[0054] (2) Pretreatment: wash and drain fresh sweet potato leaves and stems, cut into 1cm pieces;

[0055] (3) Spread the sweet potato leaves and stems pretreated in step (2) on a tray with a thickness of 1 cm, and put them in a hot air circulation oven at 65 ° C for 24 hours;

[0056] (4) Put the sweet potato leaves and stems dried in step (3) into a universal pulverizer to crush to 250 μm, and then pulverize to 20 μm by an ultrafine pulverizer;

[0057] (5) Use PA / AL / RCPP composite packaging bags to pack the sweet potato leaf and stem powder after superfine grinding in step (4) according to quantitative requirements to obtain finished products, such as image 3 shown.

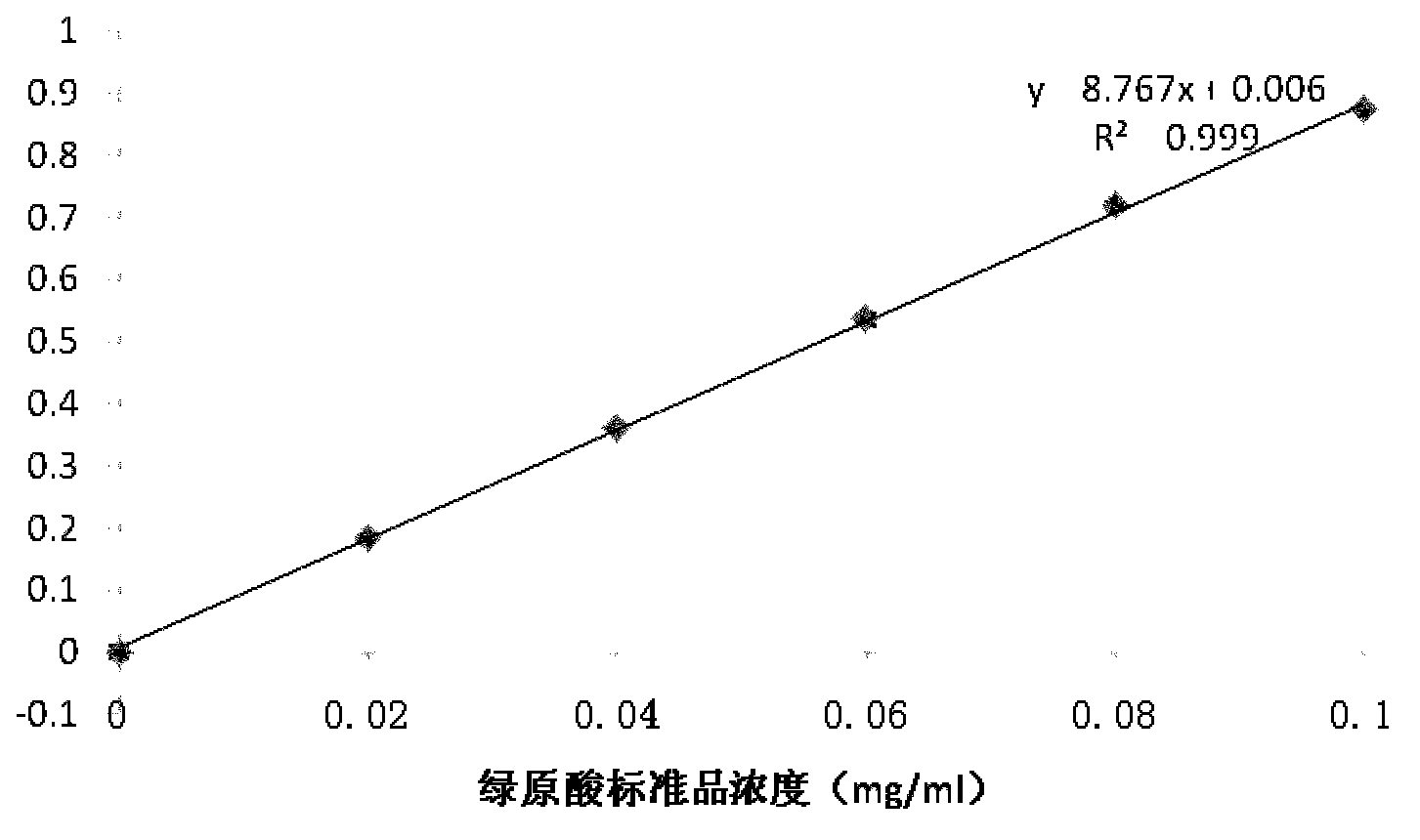

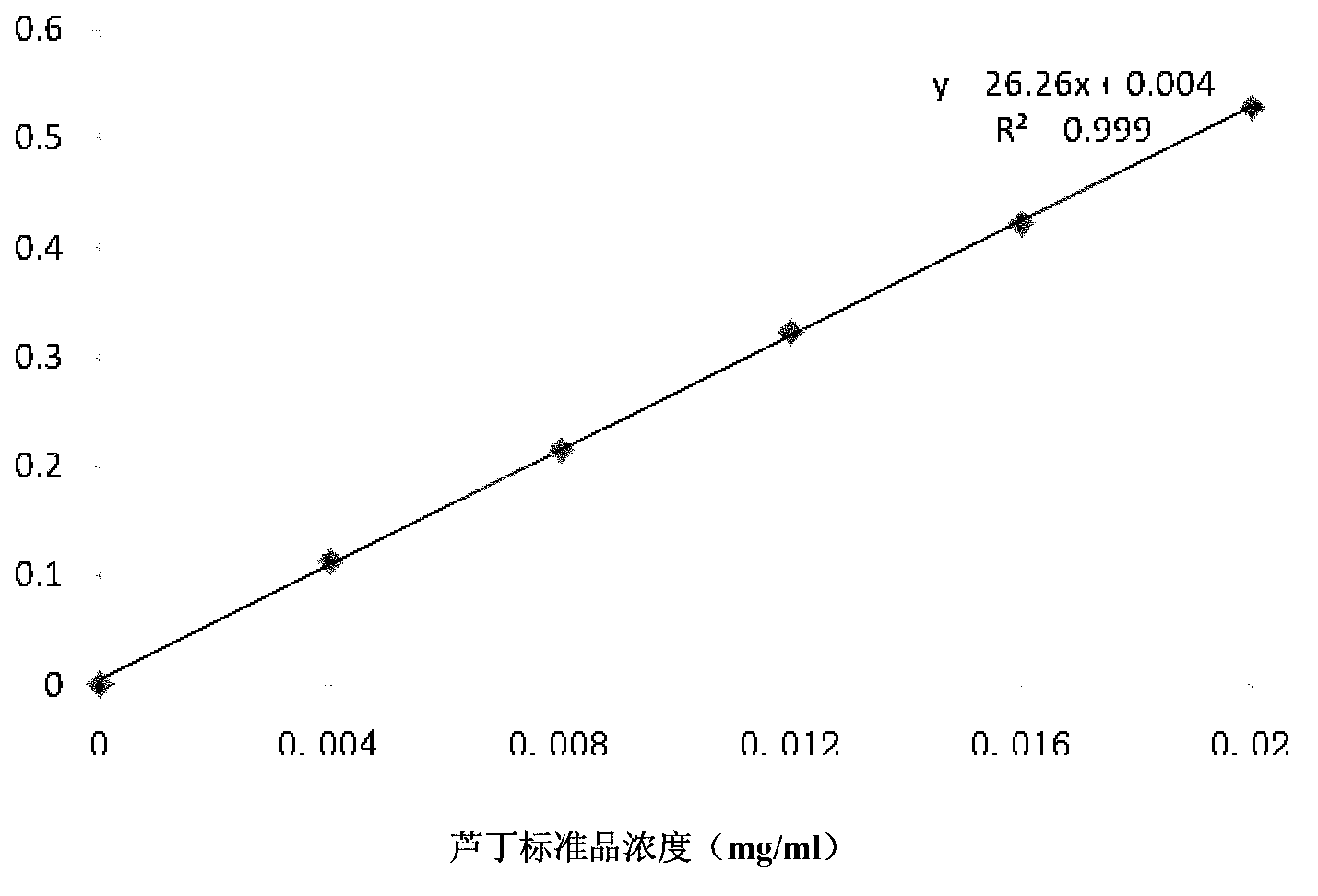

[0058] The basic component analysis and antioxidant activity evaluation test of the sweet potato leaf and stem green juice powder beverage product obtained in the above-mentioned Example 1 w...

Embodiment 2

[0063] (1) Raw materials: Fresh Ningzi No. 1 sweet potato leaves and stems are used as raw materials for processing;

[0064] (2) Pretreatment: wash and drain fresh sweet potato leaves and stems, cut into 1cm pieces;

[0065] (3) Spread the sweet potato leaves and stems pretreated in step (2) on a tray with a thickness of 1 cm, and put them in a hot air circulation oven at 65 ° C for 24 hours;

[0066] (4) Put the sweet potato leaves and stems dried in step (3) into a universal pulverizer to crush to 250 μm, and then pulverize to 20 μm by an ultrafine pulverizer;

[0067] (5) Packing the sweet potato leaf and stem powder superfinely pulverized in step (4) according to the quantitative requirements by using PA / AL / RCPP composite packaging bag to obtain a finished product.

[0068] The basic component analysis and antioxidant activity evaluation test of the sweet potato leaf and stem green juice powder beverage product obtained in the above-mentioned Example 2 are shown in Table...

Embodiment 3

[0073] (1) Raw materials: Fresh Xinxiang No. 1 sweet potato leaves and stems are used as raw materials for processing;

[0074] (2) Pretreatment: wash and drain fresh sweet potato leaves and stems, cut into 1cm pieces;

[0075] (3) Spread the sweet potato leaves and stems pretreated in step (2) on a tray with a thickness of 1 cm, and put them in a hot air circulation oven at 50 ° C for 36 hours;

[0076] (4) Put the sweet potato leaves and stems dried in step (3) into a universal pulverizer to crush to 500 μm, and then pulverize to 25 μm in an ultrafine pulverizer;

[0077] (5) Packing the sweet potato leaf and stem powder superfinely pulverized in step (4) according to the quantitative requirements by using PA / AL / RCPP composite packaging bag to obtain a finished product.

[0078] The basic component analysis and antioxidant activity evaluation test of the sweet potato leaf and stem green juice powder beverage product obtained in the above-mentioned Example 3 are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com