Visual high-temperature fluidized bed

A high-temperature fluidized bed and fluidized bed technology, applied in the direction of chemical/physical processes, chemical instruments and methods, etc., can solve the problems of inability to realize visual observation and shooting, opacity of thermal insulation materials, etc., and achieve real and reliable research results with low cost , to ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

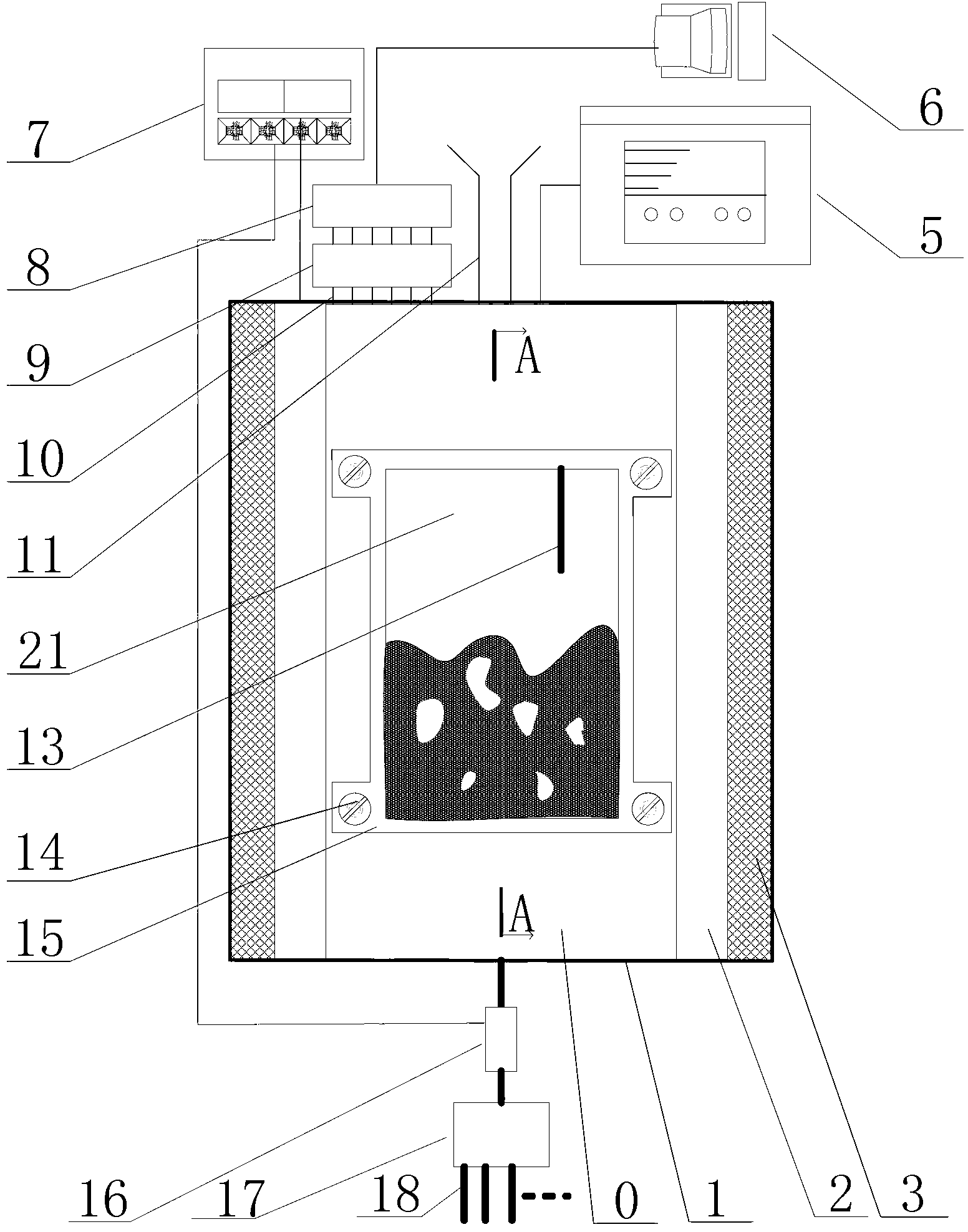

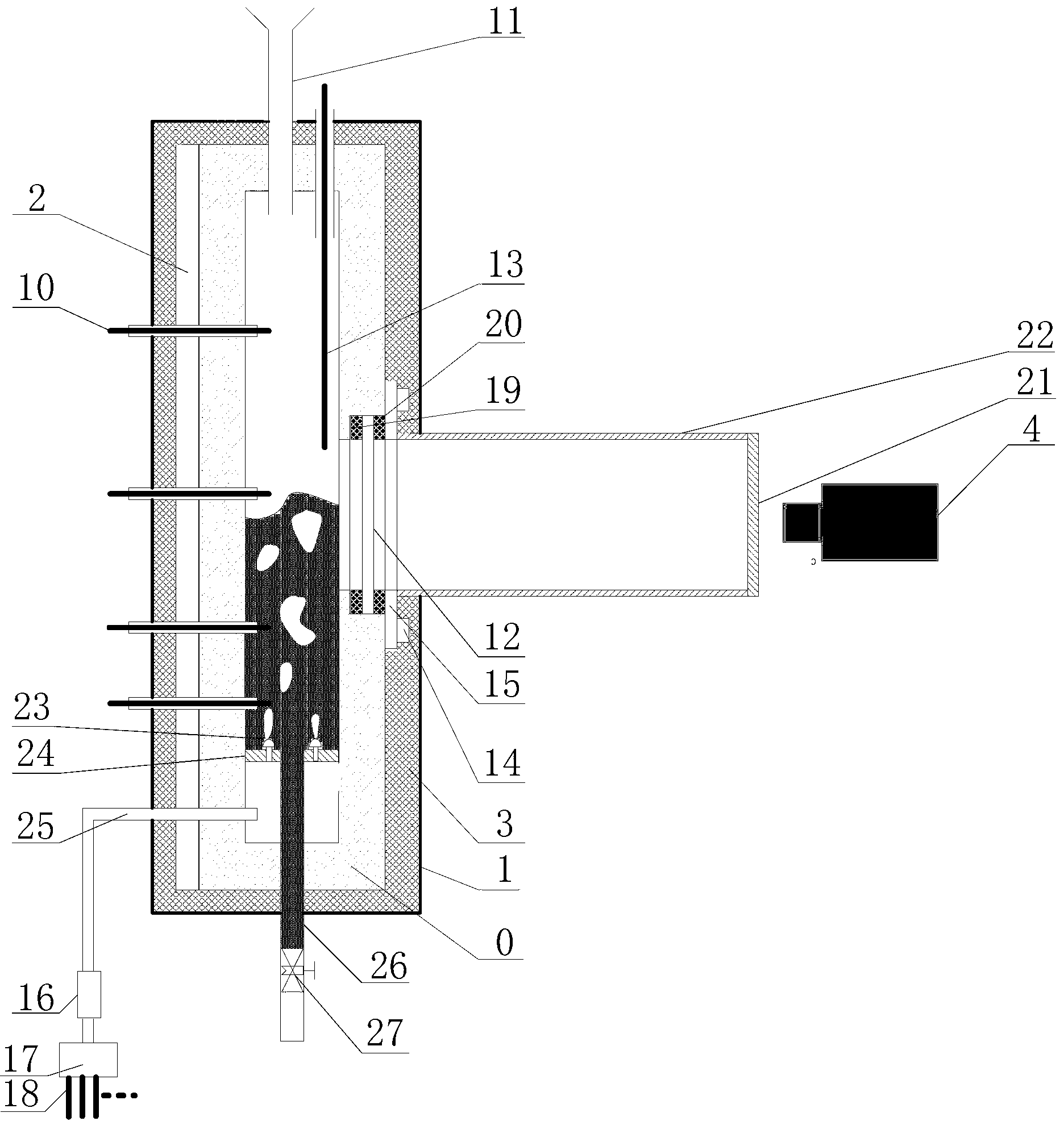

[0021] The present invention will be further explained below in conjunction with the accompanying drawings.

[0022] use figure 1 and figure 2 The device shown realizes the observation of the fluidized state of the bed material in the fluidized bed at high temperature.

[0023] Visualized high-temperature fluidized bed for observing the fluidized form of bed material at high temperature, including fluidized bed body 0, insulation cotton shell 1, bed electric heater 2, insulation cotton 3, CCD high-speed camera 4, online gas analysis Instrument 5, computer 6, temperature control system 7, data collector 8, temperature converter 9, thermocouple 10, exhaust pipe 11, high temperature resistant quartz glass 12, sampling gun 13, screw 14, annular sealing cover 15, air conditioning Device 16, gas mixer 17, intake pipe 18, high temperature resistant sealing gasket a19, high temperature resistant sealing gasket b20, anti-infrared glass 21, radiation shield 22. Among them, the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com