Dissimilar steel welding process of check door and tubing

A dissimilar steel and piping technology, applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as difficulty, affecting safe operation of pipelines, and no cracks, etc., so as to improve welding quality and reduce production and operation cost, and the effect of reducing the repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

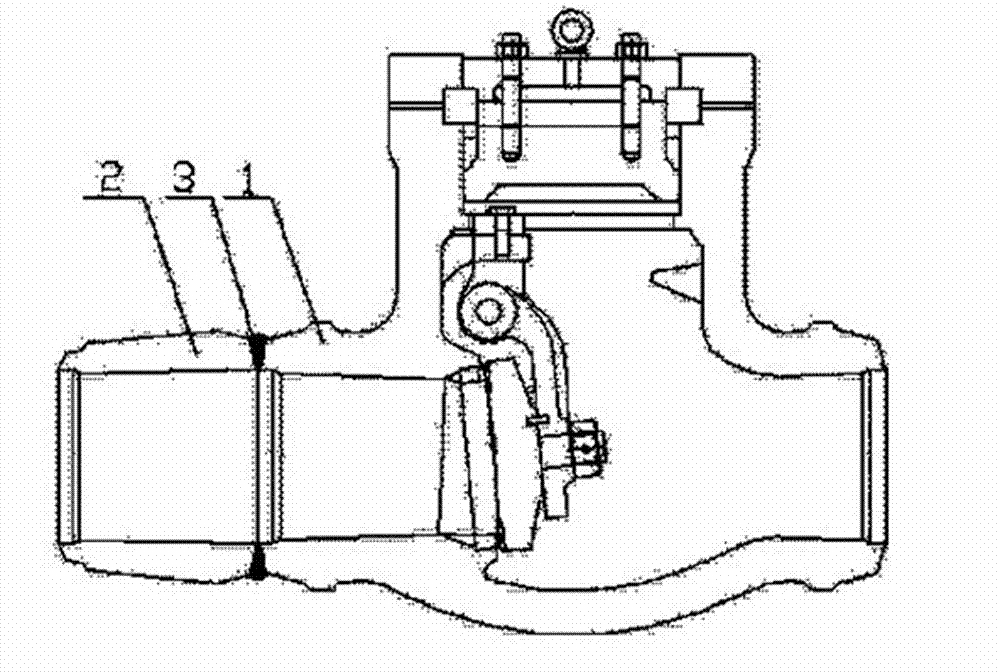

[0021] In order to further introduce the present invention, introduce below in conjunction with description:

[0022] The welding process of the dissimilar steel of the check door piping, the welding process follows the following steps:

[0023] Step 1: Confirm that the material of valve body 1 is WC9 alloy steel;

[0024] Step 2: Confirm that the material of the piping 2 matched with the valve body 2 is F91 heat-resistant steel;

[0025] The third step: choose R40 welding wire and R407 welding rod, the diameter of the welding rod is Φ4mm, Φ5mm;

[0026] Step 4: Use a heating belt to preheat the workpiece, and the preheating temperature is 200 ° C ~ 250 ° C;

[0027] Step 5: Baking the electrode, the baking condition is 200℃-250℃×1h;

[0028] Step 5: Set the welding current as Φ4: 100 A~ 140A; Φ5: 140 A~ 180A;

[0029] Step 6: Connect valve body 1 and piping 2 by spot welding;

[0030] Step 7: Weld with R40 welding wire;

[0031] Step 8: Weld the surface with R407 weldi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap