Production technology of decoration combined by bamboo skin formed in cutting way

A technology for making crafts and decorations, applied in decorative arts, special decorative structures, etc., can solve the problem that new bamboo materials do not have in-depth exploration potential, and achieve the effect of strong decorative meaning, beautiful shape, and beautifying the home environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Described decoration manufacturing process comprises the following steps:

[0035] 1. The laminated bamboo is subjected to high-temperature cooking or hydrogen peroxide cooking;

[0036] 2. The laminated bamboo treated in step 1 is cut into bamboo skins, backed with non-woven fiber paper, and bonded with glue;

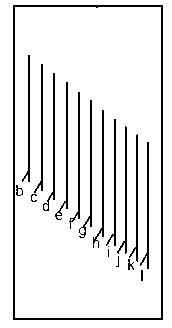

[0037] 3. Carry out several parallel equidistant cuts along the length direction of the bamboo veneer from the middle, and the length of each cutting line is equal;

[0038] 4. Fix the upper and lower parts of the uncut bamboo skin on the cylindrical support with adhesive or other methods, and the cut part is not fixed;

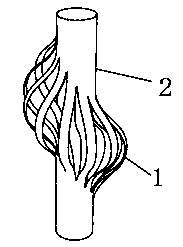

[0039] 5. Make the length of the bamboo veneer longer than the cylindrical support, so that the unfixed cut part naturally arches outwards, forming a group of scattered and orderly arcs, forming a combined shape and becoming an ornament.

Embodiment 2

[0041] Described decoration manufacturing process comprises the following steps:

[0042] 1. The laminated bamboo is subjected to high-temperature cooking or hydrogen peroxide cooking;

[0043] 2. The laminated bamboo treated in step 1 is cut into bamboo skins, backed with non-woven fiber paper, and bonded with glue;

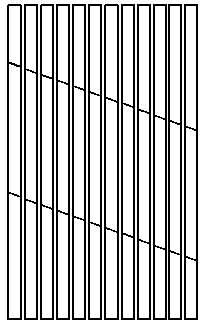

[0044] 3. Cut the bamboo skin into several parallel and equal width bamboo strips, and determine two parallel oblique lines or two parallel straight lines near the middle of the bamboo strips as reference lines;

[0045] 4. Fix the upper part and the lower part of the two oblique lines or two straight lines on the cylindrical support with adhesive or other methods, and the part between the two oblique lines or two straight lines is not fixed;

[0046] 5. The length of the bamboo veneer is greater than the height of the column support, so that the unfixed cut part naturally arches outwards, forming a group of scattered and orderly arcs, forming a combined shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com