Gypsum type brine purification technique using lime-carbon dioxide method

A carbon dioxide and brine purification technology, applied in the direction of alkali metal chloride, etc., can solve the problems of wasting heat energy of salt-making mother liquor, high energy consumption of evaporation, and short brushing cycle, so as to reduce steam consumption, low steam consumption, and short production cycle long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

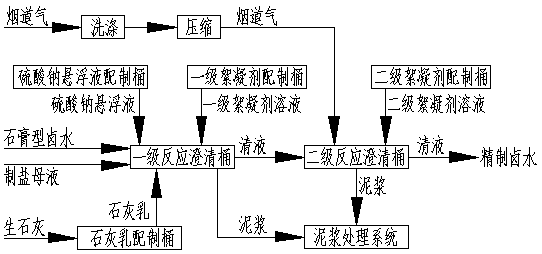

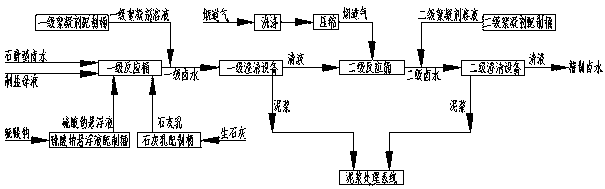

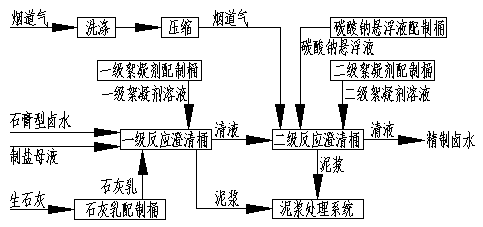

[0037] Embodiment 1 adopts attached figure 1 The intermittent gypsum type type brine purification process; Embodiment 2 adopts the attached figure 2 Continuous gypsum type brine purification process; Embodiment 3 adopts the attached image 3 The intermittent gypsum type brine purification process; Embodiment 4 adopts the attached Figure 4 Continuous gypsum type brine purification process.

[0038] Example 1:

[0039] The composition of gypsum brine is: H 2 O: 882.7g / l; NaCl: 310 g / l; CaSO 4 : 4.52g / l; CaCl2 : 2.25 g / l; MgCl 2 : 0.44g / l; if the salt workshop produces 10t of industrial salt, the purification workshop needs to process 32.8m 3 gypsum brine and 26.3m 3 Mother liquor for salt production, primary reaction, first add 140.1kg of Na at a stirring speed of 20-100r / min 2 SO 4 , then add 60kg CaO and continue to stir and react for 5 hours, then add 0.12kg of primary flocculant, stop stirring and clarify for 2 hours, measure the Mg in the clear liquid 2+ and PH ...

Embodiment 2

[0041] The composition of gypsum brine is: H 2 O: 882.6g / l; NaCl: 310 g / l; CaSO 4 : 4.50g / l; CaCl 2 : 2.25 g / l; MgCl 2 : 0.44g / l; if the salt workshop produces 10t of industrial salt, the purification workshop needs to process 32.9m 3 gypsum brine and 26.2m 3 Mother liquor for salt production, primary reaction Add 141.5kg of Na at a continuous stirring speed of 20-100r / min 2 SO 4 , and then add 62kg CaO, and ensure that the residence time is more than 5 hours, transfer to the primary clarification equipment, and add 0.12kg of primary flocculant at the same time, measure the Mg in the clear liquid 2+ and pH values are 0.1ppm and 12.5 respectively; the clear liquid from the primary clarification equipment is transferred to the secondary reaction barrel, and the secondary reaction is fed into the flue gas 295Nm at a continuous stirring speed of 20-100r / min. 3 , and ensure that the residence time is more than 2 hours, transfer to the secondary clarification equipment, add ...

Embodiment 3

[0043] The composition of gypsum brine is: H 2 O: 904.2g / l; NaCl: 292g / l; CaSO 4 : 3.13g / l; CaCl 2 : 0.66 g / l; MgCl 2 : 0.44g / l; if the salt workshop produces 10t of industrial salt, the purification workshop needs to process 36m 3 gypsum brine and 9.7m 3 Mother liquor for salt production, primary reaction Add 48.9kg of CaO at a stirring speed of 20-100r / min, continue stirring for 5 hours, then add 0.09kg of primary flocculant, stop stirring for 2 hours, and measure the Mg in the clear liquid 2+ and PH values are 0.1ppm and 12.5 respectively; transfer the primary clear liquid to the secondary reaction, and the secondary reaction is fed into the flue gas 225Nm at a stirring speed of 20-100r / min 3 , continue to stir, add 63.5kg of sodium carbonate after 2 hours, add 0.09kg of secondary flocculant after continuing to stir for 2 hours, stop stirring for clarification for 2 hours, measure the Ca in the clear liquid 2+ , Mg 2+ And the pH value is 4.8ppm, 0.1ppm and 11 respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com