Lithium-aluminum alloy, and production method and use thereof

A lithium-aluminum alloy, metal lithium technology, applied in electrical components, circuits, battery electrodes, etc., can solve the problems of safe electrode active material loss, reduce lithium anode mass specific energy, increase interface impedance, etc., to improve dendrite suppression effect. , Improve the effect of charge-discharge cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 Preparation of lithium aluminum alloy of the present invention

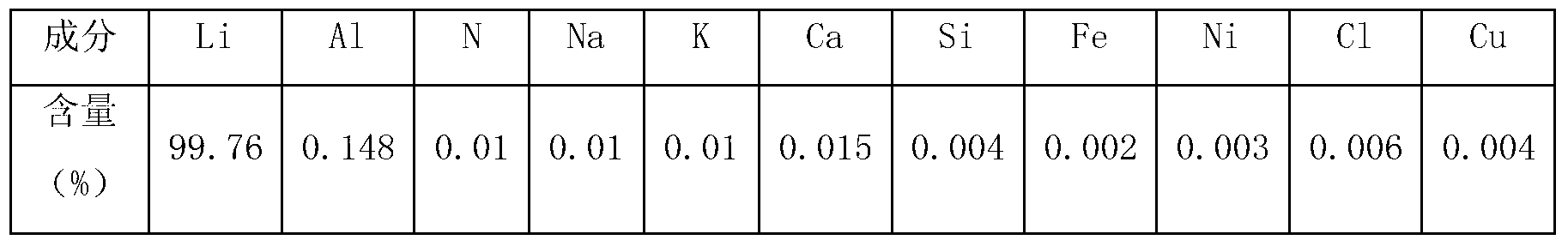

[0028] Put the prepared metal lithium and metal aluminum into the crucible according to the ratio of 99.80:0.15 (the proportion of lithium and aluminum in the embodiment of the present invention is the weight ratio), vacuumize (0.1Pa), and pass argon (9×10 4 Pa) replaced twice to ensure that the total amount of oxygen and nitrogen in the tank is not greater than 15ppm. Start to heat up (300°C / h), the temperature rises to 220°C, and the melting time is 2h. After the alloying is completed, the temperature is lowered to 210°C for casting. After the casting is completed and the temperature of the alloy ingot reaches the ambient temperature, the tank is opened for demoulding and sampling. The samples taken out are quickly vacuum-packed, weighed, and recorded. The composition of the obtained lithium aluminum alloy is shown in Table 1 below.

[0029] Table 1

[0030]

Embodiment 2

[0031] Example 2 Preparation of lithium aluminum alloy of the present invention

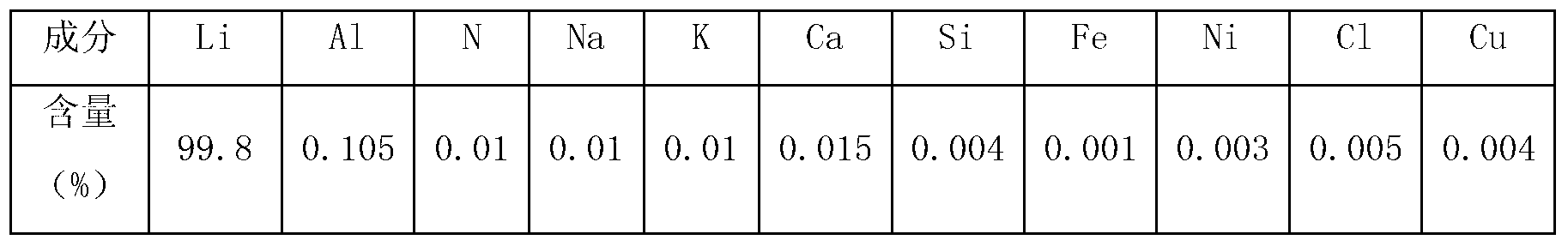

[0032] Put the prepared metal lithium and metal aluminum into the crucible according to the ratio of 99.85:0.1, vacuumize (0.1Pa), and pass argon (9×10 4 Pa) replaced twice to ensure that the total amount of oxygen and nitrogen in the tank is not greater than 15ppm. Start to heat up (300°C / h), the temperature rises to 190°C, and the melting time is 8h. After the alloying is completed, the temperature is lowered to 190°C for casting. After the casting is completed and the temperature of the alloy ingot reaches the ambient temperature, the tank is opened for demoulding and sampling. The samples taken out are quickly vacuum-packed, weighed, and recorded. The composition of the obtained lithium aluminum alloy is shown in Table 2 below.

[0033] Table 2

[0034]

Embodiment 3

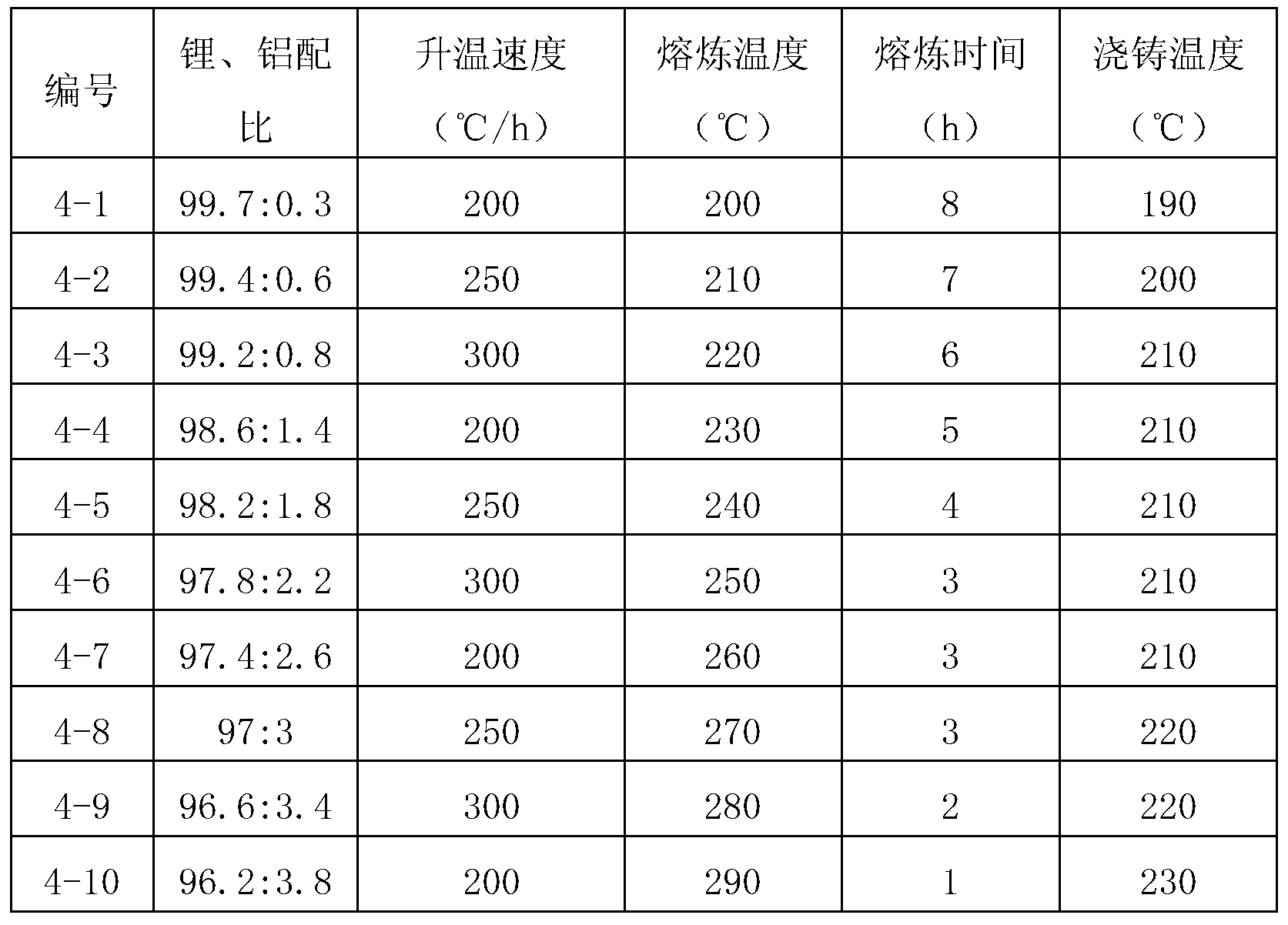

[0035] Example 3 Preparation of lithium aluminum alloy of the present invention

[0036] Put the prepared metal lithium and metal aluminum into the crucible according to the ratio of 96:4, vacuum (0.1Pa), and argon (9×10 4 Pa) replaced twice to ensure that the total amount of oxygen and nitrogen in the tank is not greater than 15ppm. Start to heat up (300°C / h), the temperature rises to 300°C, and the melting time is 1h. After the alloying is completed, the temperature is lowered to 210°C for casting. After the casting is completed and the temperature of the alloy ingot reaches the ambient temperature, the tank is opened for demoulding and sampling. The samples taken out are quickly vacuum-packed, weighed, and recorded. The composition of the obtained lithium aluminum alloy is shown in Table 3 below.

[0037] table 3

[0038] Element

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com