A kind of infrared low emissivity green stealth paint and preparation method thereof

A stealth coating, low emissivity technology, applied in textiles, papermaking, fiber processing, etc., can solve the problem of limiting coloring pigments, etc., and achieve a good stealth compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1, preparation green stealth paint

[0060] At room temperature, weigh 20 parts of phthalocyanine green pigment, 2 parts of protective colloid (sodium alginate), 5 parts of functional filler flake copper powder (particle size is 600 mesh), 15 parts of adhesive polyacrylate (average molecular weight 15000), 3 parts of toner (carbon black), 55 parts of deionized water, after mixing and stirring for 3 hours at a speed of 3000 rpm under normal temperature and pressure, a low-emissivity coating T1 was obtained, which was applied to the Shanghai Physics Technology of the Chinese Academy of Sciences The IR-2 dual-band emissivity measuring instrument developed by the research institute measured the emissivity to be 0.76.

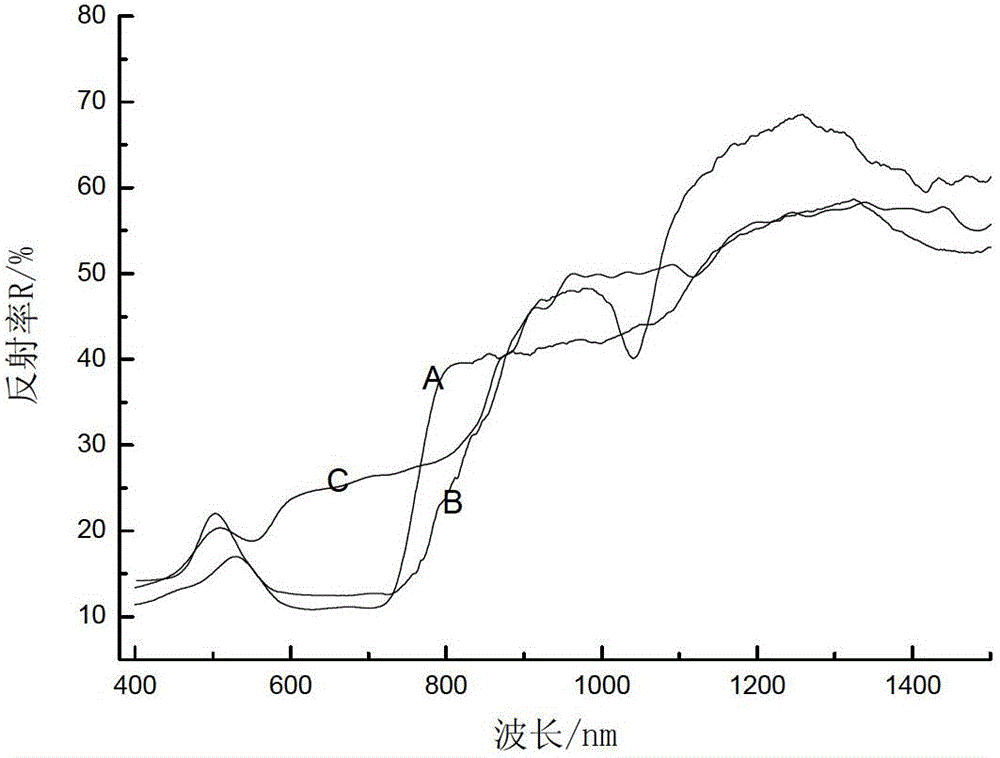

[0061] The visible light-near-infrared reflectivity test result of the polyester / cotton blended fabric coated with the green stealth paint prepared by the present embodiment is as follows: figure 1As shown in the middle A curve, it can be seen tha...

Embodiment 2

[0063] Embodiment 2, preparation green stealth paint

[0064] At room temperature, weigh 15 parts of iron oxide green pigment, 5 parts of green pigment, 3 parts of protective colloidal cellulose ether (methyl cellulose), 15 parts of functional filler flake aluminum powder (particle size is 300 mesh), bond 10 parts of polyacrylate (molecular weight: 15,000), 5 parts of polyurethane (molecular weight: 10,000), 2.5 parts of toner (carbon black), 44.5 parts of deionized water, stirring at a speed of 3500 rpm under normal temperature and pressure After 1.5 hours, the low-emissivity coating T2 was obtained, and the emissivity was measured as 0.69 by using the IR-2 dual-band emissivity measuring instrument developed by the Shanghai Institute of Physics and Technology, Chinese Academy of Sciences.

[0065] The visible light-near-infrared reflectance test result of the polyester / cotton blended fabric coated with this coating is as follows: figure 1 As shown in the middle B curve, it c...

Embodiment 3

[0067] Embodiment 3, preparation green stealth paint

[0068] At room temperature, weigh 15 parts of chromium oxide pigment, 5 parts of iron oxide green pigment, 2 parts of protective colloid synthetic polymer thickener (sodium polyacrylate), 20 parts of functional filler flake copper powder (particle size is 1000 mesh) , 15 parts of adhesive polyacrylate (molecular weight is 15000), 3.5 parts of toner (carbon black), 39.5 parts of deionized water, after stirring for 4 hours at a speed of 4000 rpm under normal temperature and pressure, a low Emissivity coating T3, the emissivity measured by the IR-2 dual-band emissivity measuring instrument developed by Shanghai Institute of Physics and Technology, Chinese Academy of Sciences is 0.65.

[0069] The visible light-near-infrared reflectance test result of the polyester / cotton blended fabric coated with the coating prepared in this embodiment is as follows: figure 1 As shown in the middle C curve, it can be seen that the fabric ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com