Low-infrared-emissivity composite pigment and preparation method thereof

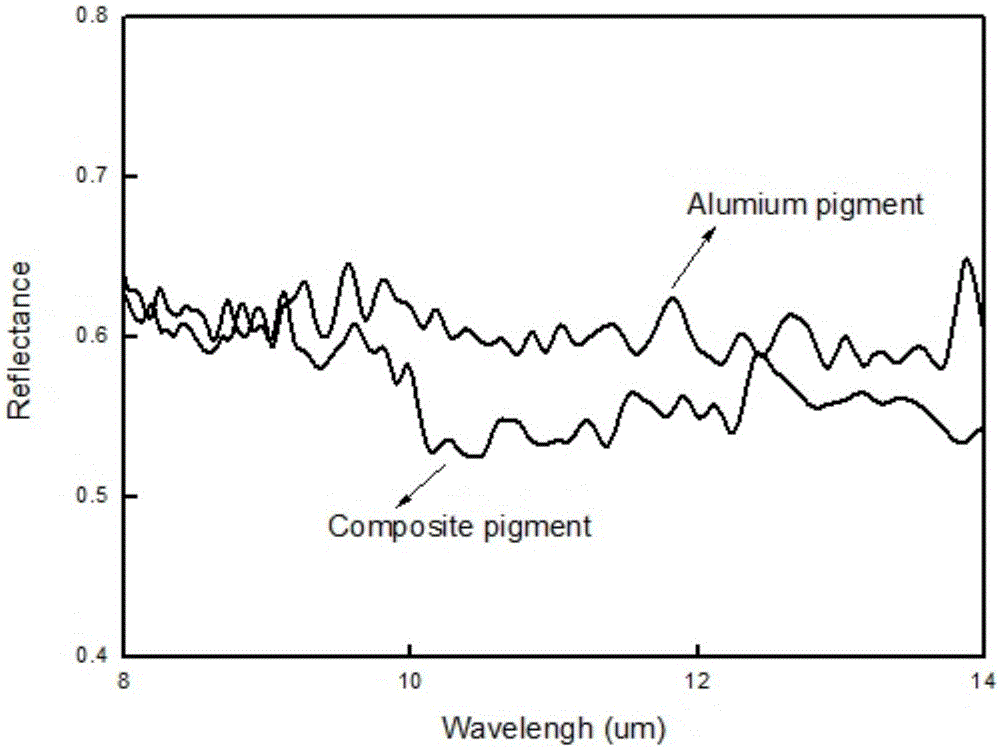

A technology with low infrared emission and infrared emissivity, which is applied in the field of energy-saving and environmentally friendly coating materials, low infrared emissivity composite pigments and its preparation, can solve the problems of poisonous metal oxides, easy pollution of the environment, and corrosion of aluminum powder. Achieve the effect of little harm to the human body, good thermal stability, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Bi(NO) 3. 5H 2 O as the solute, ethylene glycol as the solvent, formulated into Bi 3+ A bismuth nitrate solution with a concentration of 0.20 mol / L, to which a dispersant and aluminum powder are added, and the dispersant is sodium lauryl sulfate. The dispersant that adds in every liter of solvent is 0.5g, and the mol ratio of described solute and aluminum powder is 0.1:1, and the weak base solution that pH is 9 is added dropwise at a constant speed with the drip rate of 1.5ml / min after ultrasonic dispersion makes Bi in the reaction solution 3+ All precipitation; the alkaline solution is ammonia water, and the constant temperature of the reaction system is controlled at 30 degrees.

[0035] (2) Suction filtration after the reaction is completed, the filter residue is dried, and the precursor powder is obtained after grinding;

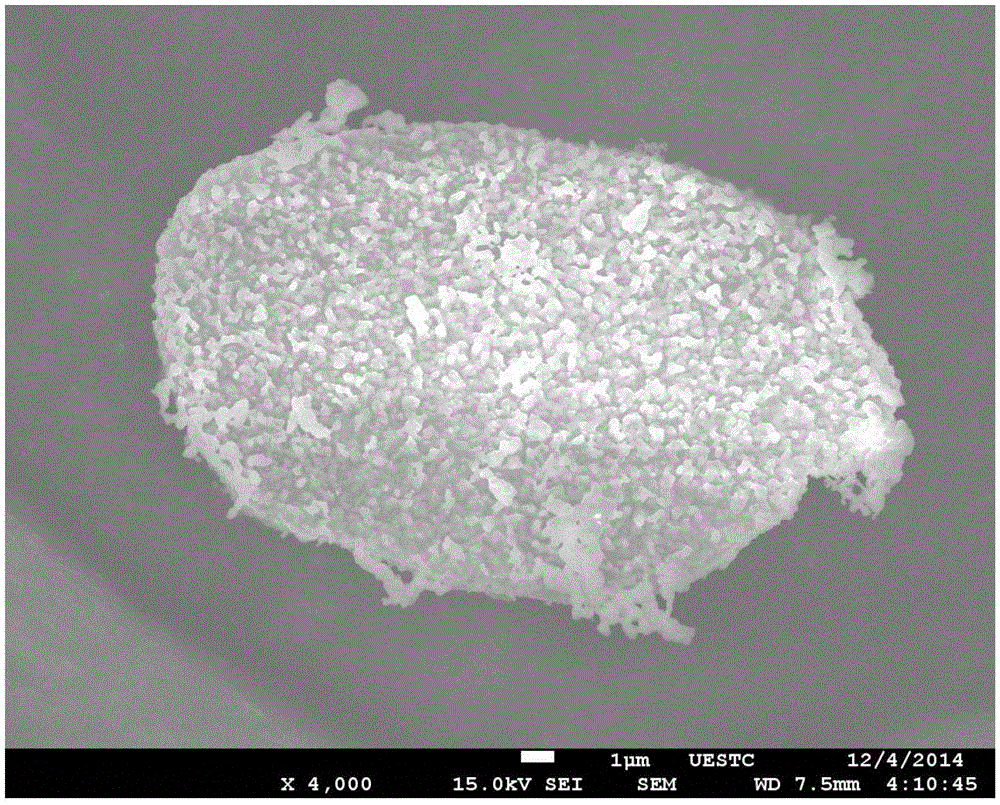

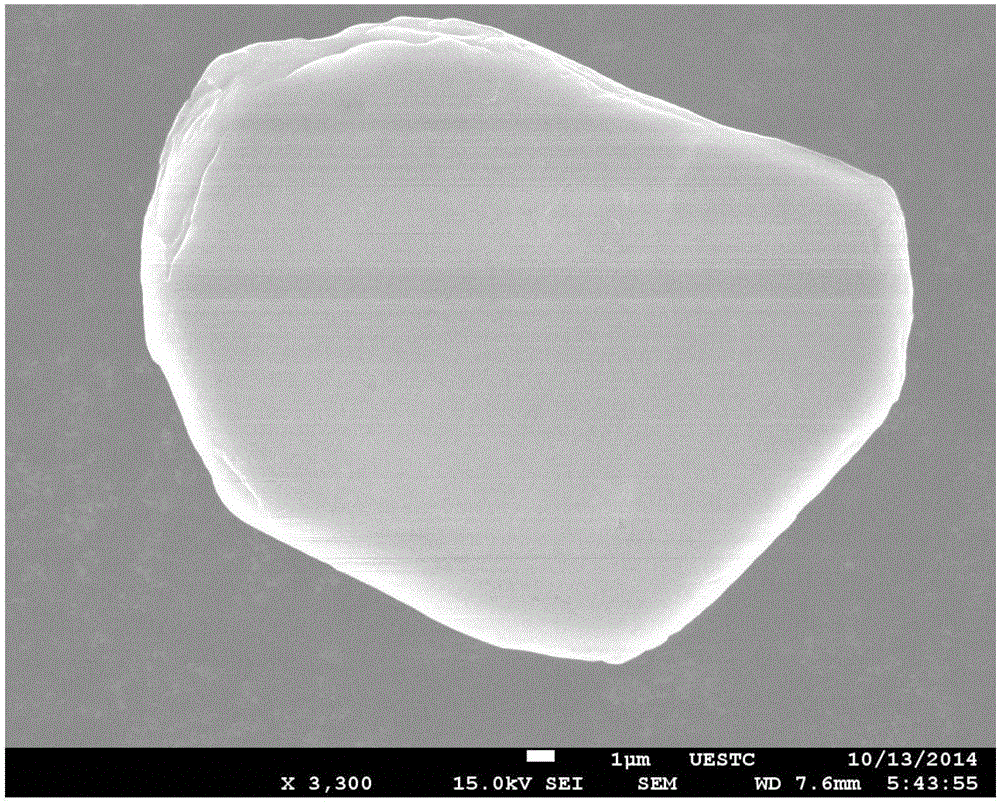

[0036] (3) Put the obtained precursor powder into a muffle furnace for calcination at 400° C. for 2 h, and obtain a low-infrared emissivi...

Embodiment 2

[0040] (1) Bi(NO) 3. 5H2O as the solute, ethylene glycol as the solvent, prepared Bi 3+ Concentration is the bismuth nitrate solution of 0.05mol / L, adds dispersing agent, aluminum powder wherein, the dispersing agent added in every liter of solvent is 0.7g, and described dispersing agent is sodium lauryl sulfate. The mol ratio of described solute and aluminum powder is 0.4:1, after ultrasonic dispersion, the weak base solution that pH value is 9 is added dropwise at a constant speed with the drip rate of 0.2ml / min to make the Bi in the reaction solution 3+ All precipitated; the alkaline solution is sodium hydroxide solution. In the step (1), the constant temperature of the reaction system is controlled at 60 degrees.

[0041] (2) Suction filtration after the reaction is completed, the filter residue is dried, and the precursor powder is obtained after grinding;

[0042] (3) Put the obtained precursor powder into a muffle furnace for calcination at 450° C. for 3 h, and obtai...

Embodiment 3

[0046] (1) Bi(NO) 3. 5H 2 O as the solute, ethylene glycol as the solvent, formulated into Bi 3+ Concentration is the bismuth nitrate solution of 0.1mol / L, adds dispersant, aluminum powder wherein, the dispersant that adds in every liter of solvent is 0.6g, and described dispersant is sodium lauryl sulfate. The mol ratio of described solute and aluminum powder is 0.2:1, after ultrasonic dispersion, the weak base solution that pH value is 8 is added dropwise at a constant speed with the drip rate of 0.5ml / min to make the Bi in the reaction solution 3+ All precipitated; the alkaline solution is ammonia water. The temperature of the reaction system was controlled at 40°C.

[0047] (2) Suction filtration after the reaction is completed, the filter residue is dried, and the precursor powder is obtained after grinding;

[0048] (3) Put the obtained precursor powder into a muffle furnace for calcination at 400° C. for 2 h, and obtain a low-infrared emissivity composite pigment af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com