Strengthening stone structure bringing convenience to construction and manufacturing technology thereof

A production process and stone technology, applied in the field of building materials, can solve problems such as fragmentation and stone damage, and achieve the effect of simplifying construction and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

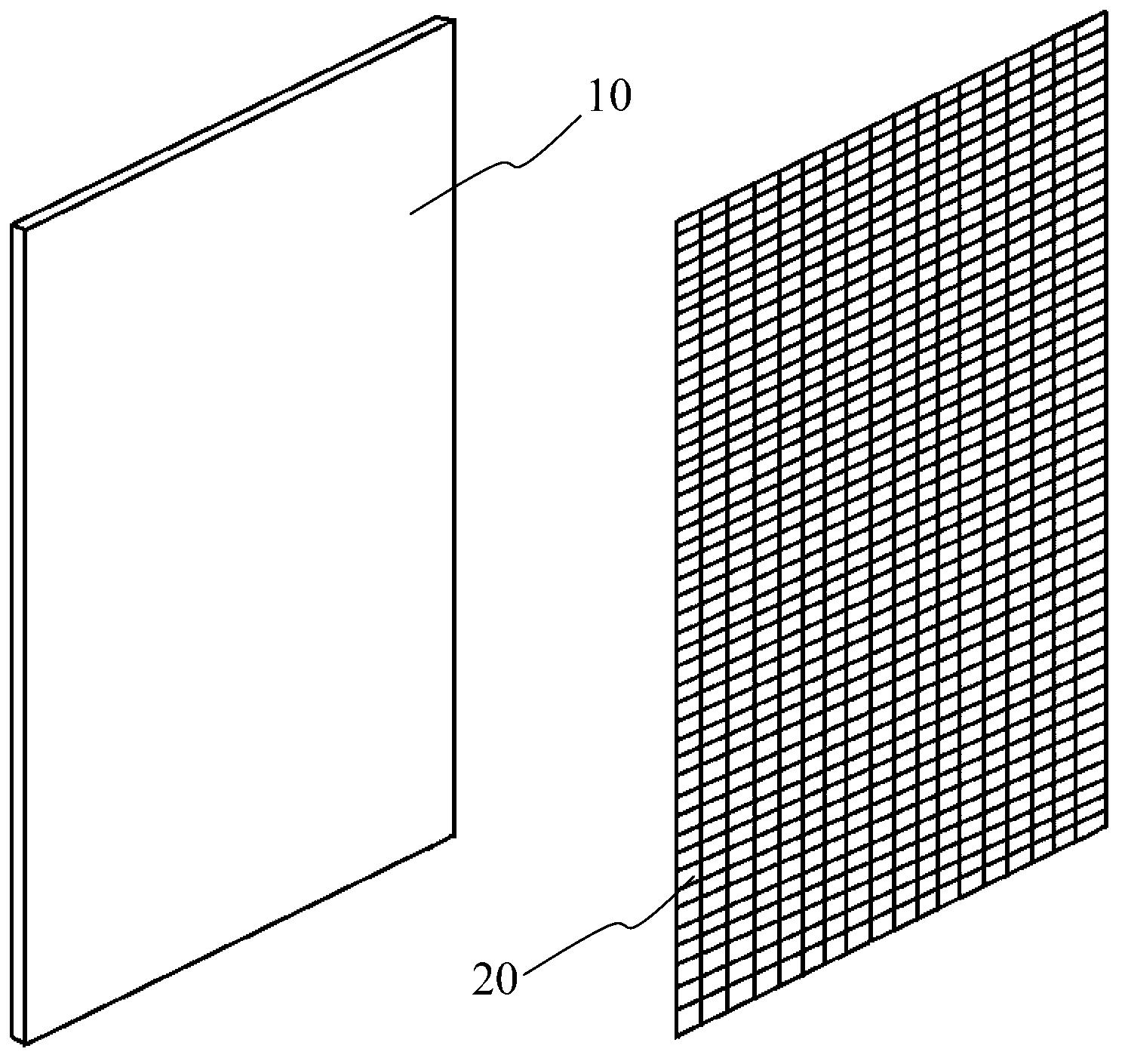

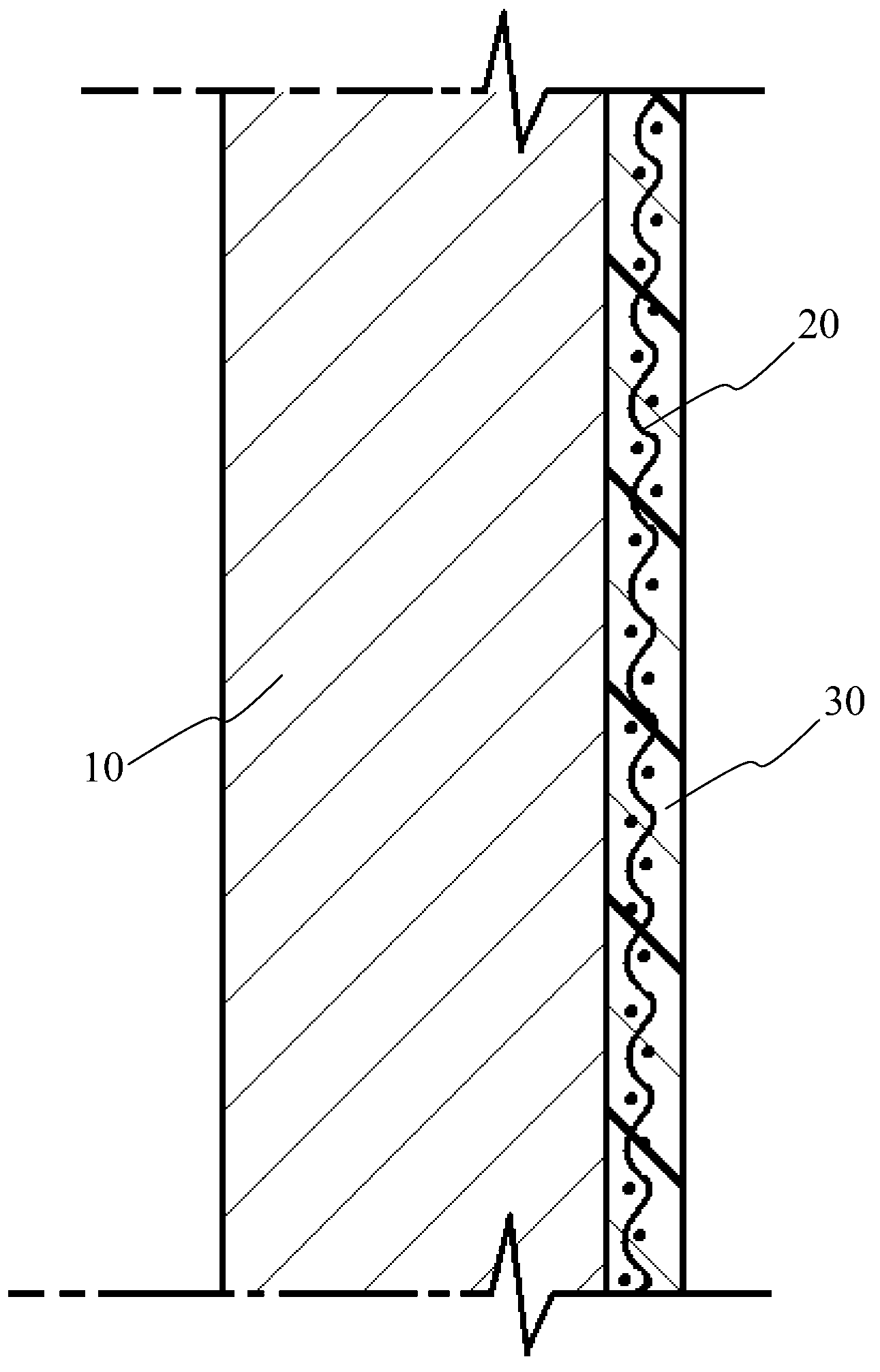

Image

Examples

Embodiment 1~7

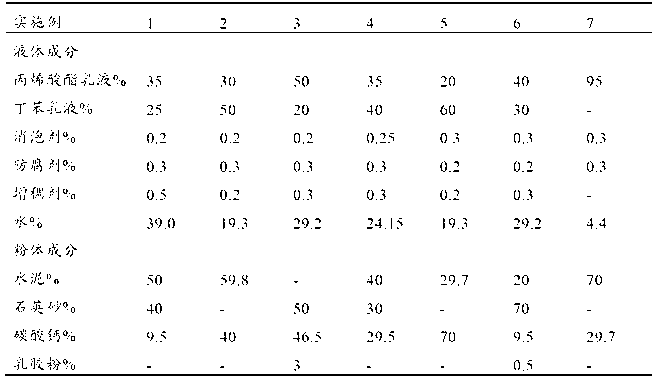

[0029] Table 1 Composition and content of liquid components and powder components in Examples 1-7 stone waterproof adhesive

[0030]

[0031]

[0032] Remarks: The content percentage of the composition in the liquid component refers to the percentage of the total weight of the liquid component; the content percentage of the composition in the powder component refers to the percentage of the total weight of the powder component.

[0033] Table 2 The ratio of the liquid component and the powder component in the stone waterproof back glue of Examples 1 to 7

[0034]

[0035] Stir and mix the liquid component and the powder component (the composition and content of which are shown in Table 1) in the stone waterproof adhesive of Examples 1 to 7 in the ratio in Table 2 to obtain the stone waterproof adhesive of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com