Fiber filtering membrane solid-liquid microextraction method and device

A fiber filter membrane and filter membrane technology, which is applied in the field of extraction of target analytes, can solve problems such as difficulty, poor reproducibility, and complicated operation of liquid-phase microextraction technology, so as to solve volatilization and loss, and simplify complex processes and devices. , the effect of improving the detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

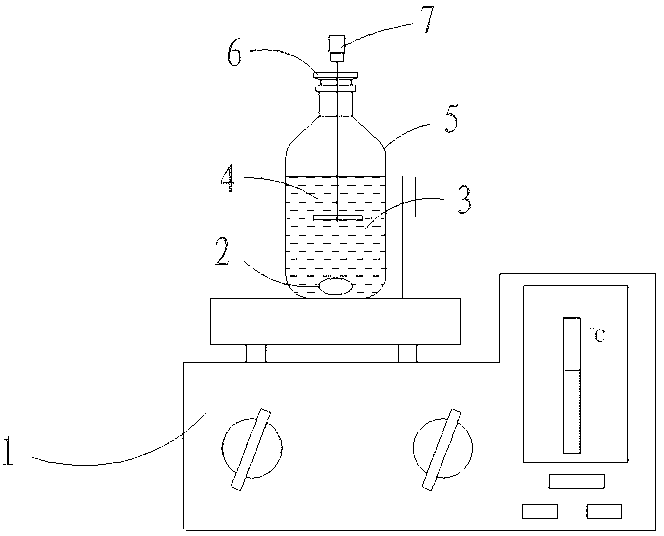

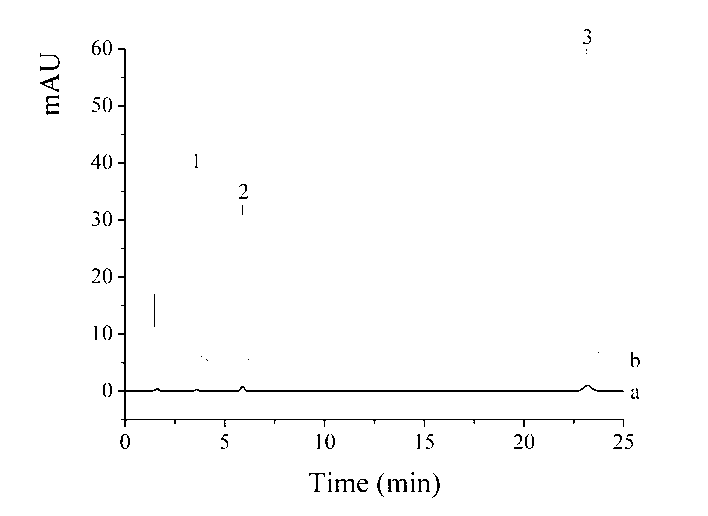

[0037] Example 1 Solid / liquid microextraction simultaneously concentrates three kinds of phenylacrylic acid compounds

[0038] 1. The present invention combines high performance liquid chromatography to simultaneously concentrate three kinds of phenylacrylic acid compound reference substances

[0039] Take a 10mL vial with a rubber cap, add 1.0mL reference substance mixed solution (the concentration of the three phenylacrylic acid compound reference substances is 8 μg / mL), 1.2g NaCl and 9 mL 0.1 mol / L HCl solution, to make the phase solution pH=1. Put in a stir bar (8 mm×4 mm) and place it on a magnetic stirrer. Cut the washed and dried organic filter membrane into small pieces of 1 cm square, soak it in heptanol for 30 s, take it out with tweezers, and gently press the filter membrane on the absorbent paper to wipe off the excess extraction on the surface of the filter membrane. solvent. Insert the needle of the microsyringe vertically into the rubber cap of the vial, cla...

Embodiment 2

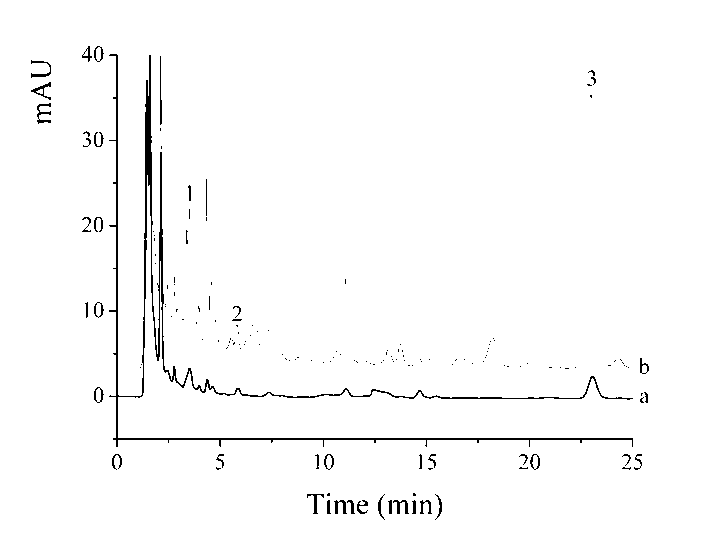

[0049] Example 2 Solid / Liquid Microextraction Simultaneous Concentration of 5 Kinds of Proberberine-Type Alkaloids

[0050] 1. Simultaneous concentration of five original berberine-type alkaloid reference substances by membrane / solvent-solid / liquid microextraction combined with high performance liquid chromatography

[0051] Take a 10 mL vial with a rubber cap, add 1.0 mL of the reference substance mixed solution (the concentration of the five alkaloid reference substances is 8 μg / mL) and 1×10 -3 9 mL of mol / L NaOH solution to make the pH of the donor phase solution = 11. Put a stir bar (8 mm × 4 mm) on a magnetic stirrer. Cut the washed and dried organic filter membrane into small pieces of 1 cm square, soak it in heptanol for 30 s, take it out with tweezers, and gently press the filter membrane on the absorbent paper to wipe off the excess extraction on the surface of the filter membrane. solvent. Insert the needle of the micro-syringe vertically into the rubber cap, cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com