Pre-alignment device and method of square substrates

A pre-alignment and substrate technology, which is applied to the exposure devices, optics, instruments, etc. of the photoengraving process, can solve the problems of robot handling errors, easy pollution, errors, etc., and achieves improved measurement accuracy, economic efficiency, and high alignment accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the technical content of the present invention, specific embodiments are given together with the attached drawings for description as follows.

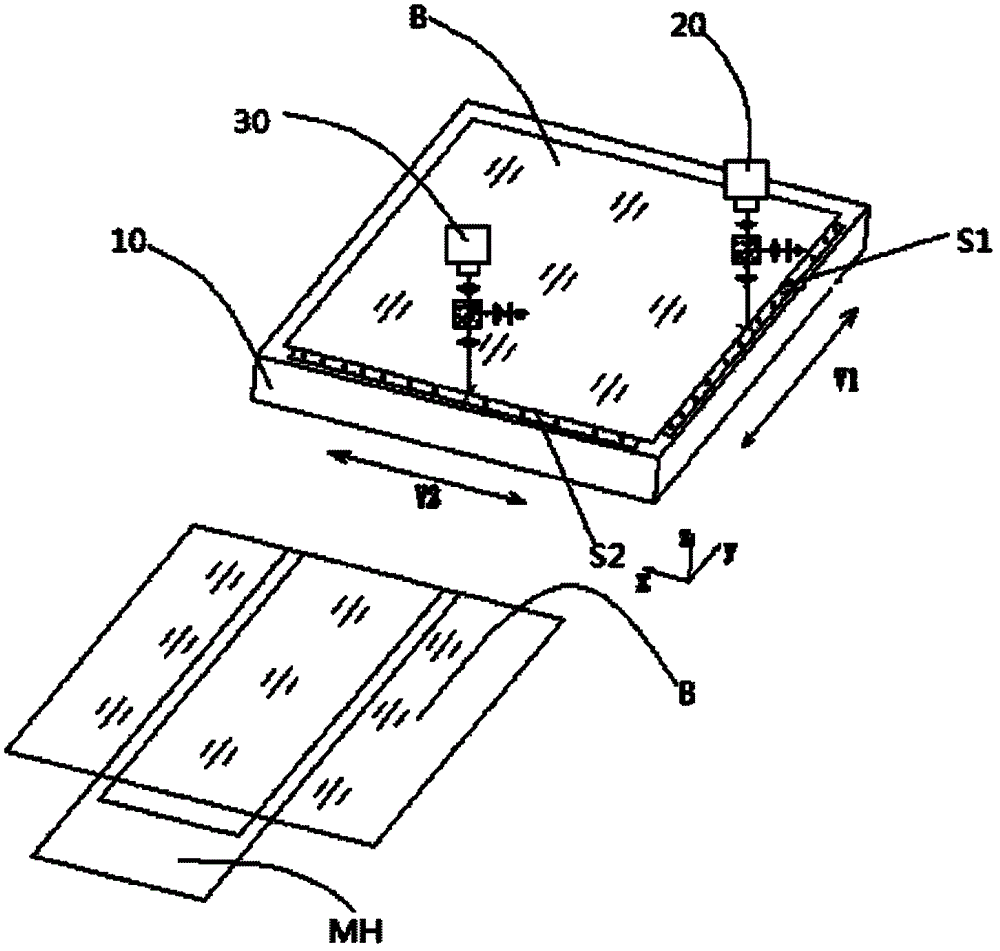

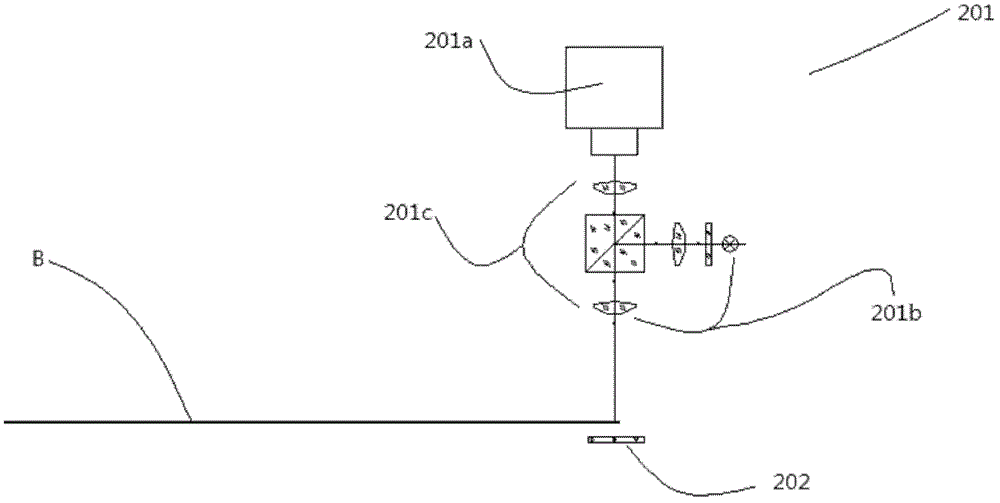

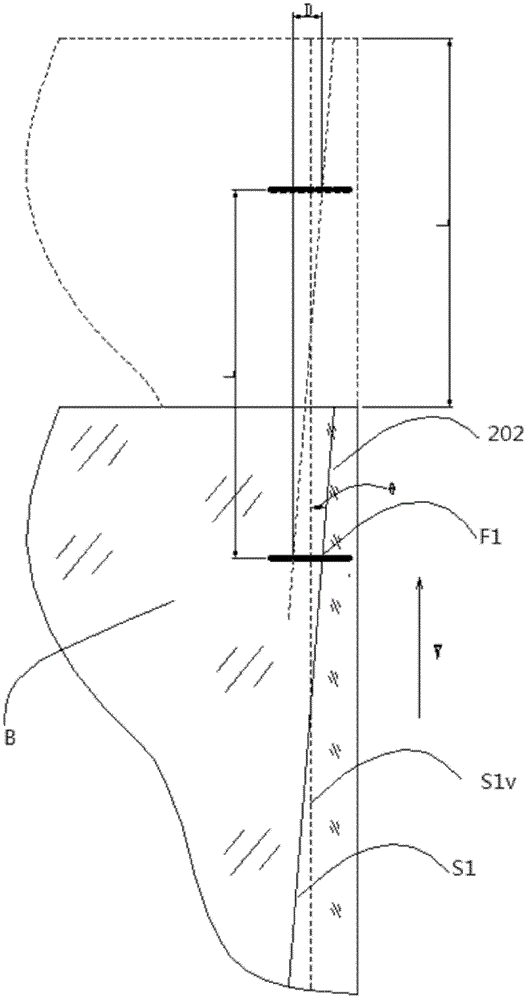

[0024] figure 1 Shown is a schematic diagram of a square substrate pre-alignment device according to an embodiment of the present invention, figure 2 is the main view of the detector, image 3 yes figure 1 The top view of the detector, Figure 4 It is a comparison diagram of the ideal substrate position and the actual post-chip substrate position. Please also refer to Figure 1 to Figure 4 .

[0025] The square substrate pre-alignment device is used to pre-align the square substrate transported by the manipulator to the workpiece table, including the workpiece table 10, the first detector 20, the second detector 30 and the controller (not shown in the figure). Wherein, the workpiece table 10 carries a square substrate B, the first detector 20 scans the first edge S1 of the square substrate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com