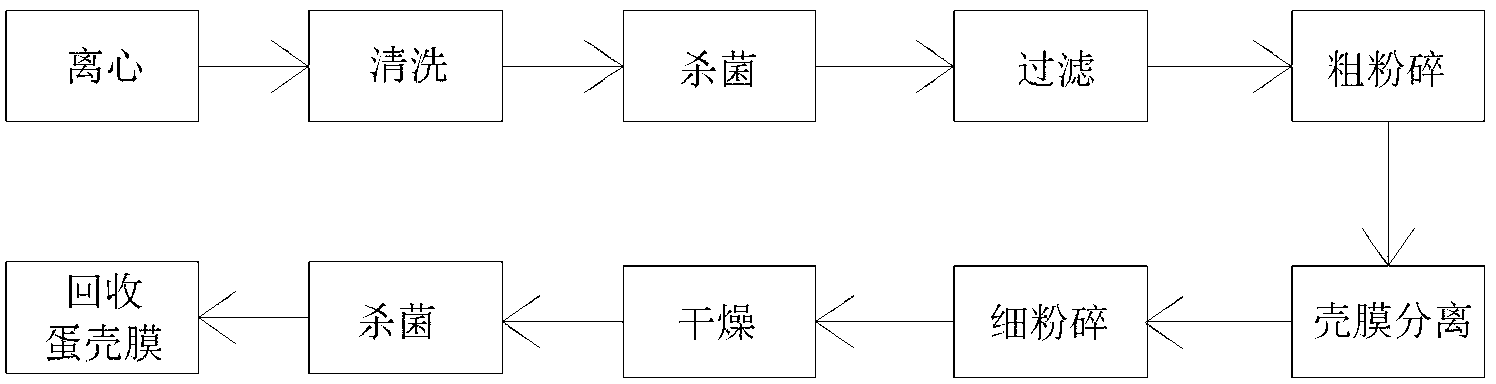

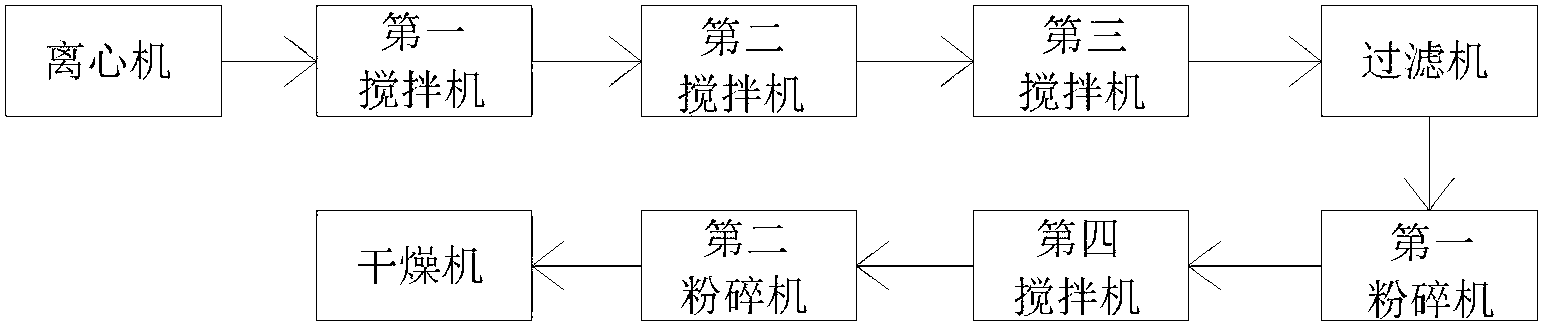

Preparation method of eggshell powder and processing device

A processing equipment and eggshell powder technology, which is applied in the field of eggshell powder preparation, can solve the problems of large consumption, large changes in shell membrane structure or composition, and achieve the effects of high efficiency, low separation cost, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Centrifuge, put the fresh eggshells separated by beating eggs into a centrifuge for centrifugation to remove the remaining egg liquid in the eggshells, and the centrifuge speed is 1000rpm.

[0040] Step 2: Cleaning, putting the centrifuged eggshells into the first mixer through an auger for stirring and cleaning, further removing the remaining egg liquid in the eggshells, and washing repeatedly three times until the water is clear.

[0041] Step 3: Sterilize, put the cleaned eggshells into the second mixer containing disinfectant with an effective chlorine concentration of 200ppm through the auger and soak for 10 minutes to sterilize the eggshells.

[0042] Step 4: Filtration, first put the sterilized eggshells into the third mixer through the auger for stirring and cleaning, remove the chloride ions in the water, and wash until the residual chlorine concentration is below 0.3mg / L, and then pass the cleaned eggshells through the auger Long feed into the filter t...

Embodiment 2

[0050] Step 1: Centrifuge, put the fresh eggshells separated by beating eggs into a centrifuge for centrifugation to remove the remaining egg liquid in the eggshells, and the centrifuge speed is 2000rpm.

[0051] Step 2: Cleaning, putting the centrifuged eggshells into the first mixer through an auger for stirring and cleaning, further removing the remaining egg liquid in the eggshells, and washing repeatedly three times until the water is clear.

[0052] Step 3: Sterilize, put the cleaned eggshell into the second blender containing disinfectant with an effective chlorine concentration of 250ppm through the auger and soak for 20 minutes to sterilize the eggshell.

[0053] Step 4: Filtration, first put the sterilized eggshells into the third mixer through the auger for stirring and cleaning, remove the chloride ions in the water, and wash until the residual chlorine concentration is below 0.3mg / L, and then pass the cleaned eggshells through the auger Long feed into the filter t...

Embodiment 3

[0061] Step 1: Centrifuge, put the fresh eggshells separated by beating eggs into a centrifuge for centrifugation to remove the remaining egg liquid in the eggshells, and the centrifuge speed is 3000rpm.

[0062] Step 2: Cleaning, putting the centrifuged eggshells into the first mixer through an auger for stirring and cleaning, further removing the remaining egg liquid in the eggshells, and washing repeatedly three times until the water is clear.

[0063] Step 3: Sterilize, put the cleaned eggshells into the second mixer containing disinfectant with an effective chlorine concentration of 300ppm through the auger and soak for 30 minutes to sterilize the eggshells.

[0064] Step 4: Filtration, first put the sterilized eggshells into the third mixer through the auger for stirring and cleaning, remove the chloride ions in the water, and wash until the residual chlorine concentration is below 0.3mg / L, and then pass the cleaned eggshells through the auger Long feed into the filter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com