Numerical control machining progressive interpolation method

An interpolation method and interpolation technology, applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve the problems of over-burning of the surface structure of parts, low processing efficiency, tool wear, etc., and achieve large contact area and high processing efficiency. Low, small contact area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

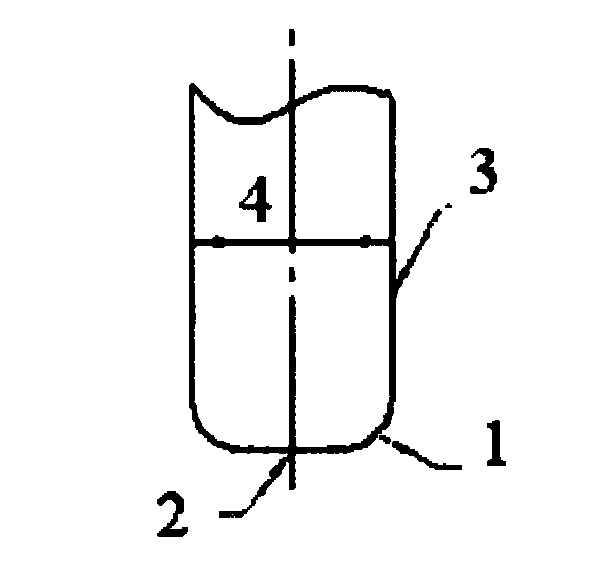

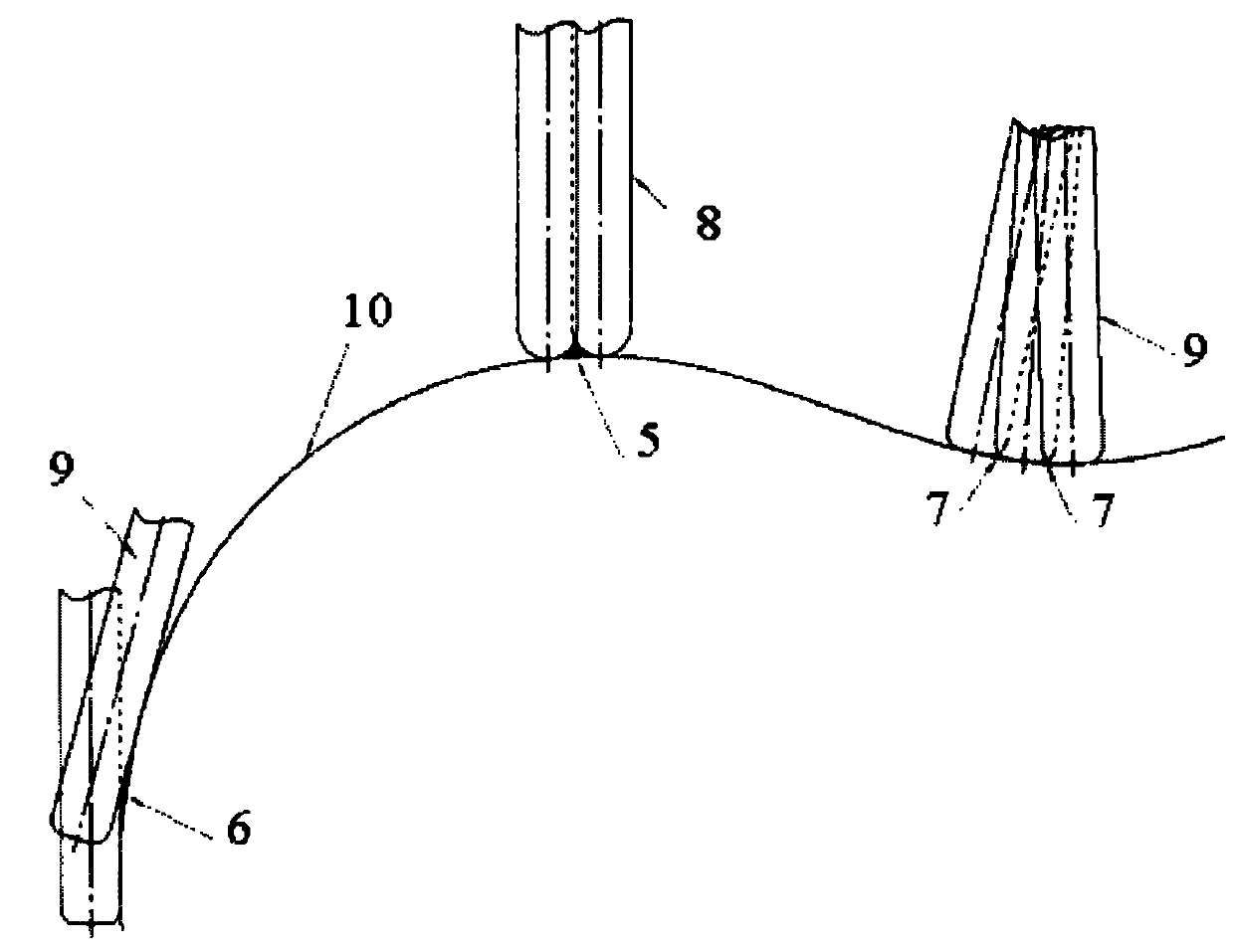

[0015] Attached below Figure 1~2 To further describe the present invention, in the figure: 1 is the bottom R of the tool, 2 is the bottom edge of the tool, 3 is the side edge of the tool, 4 is the diameter of the tool, 5 is the residual margin during line cutting, and 6 is the time of progressive interpolation of the side edge Residual margin, 7 is the residual margin when the bottom edge is progressively interpolated, 8 is the ball-end cutter, 9 is the CNC end mill, and 10 is the machined surface of the part.

[0016] The progressive interpolation method of NC machining is to make the tool axis direction parallel (or perpendicular) to the cutting point position of the curved surface during the processing, and use the processing tolerance of the curved surface to reasonably distribute the processing amount of the axial (or radial) layer to realize Envelope processing of curved surfaces; the contour of the curved surface processed by the progressive interpolation method of CNC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com