Composite material for container base plate and preparation method thereof

A technology for container floor and composite material, applied in the field of composite materials for container floor and its preparation, can solve the problems of application influence, high bamboo hardness, shortage of hardwood, etc., and achieve the effects of easy recycling, easy cleaning, and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

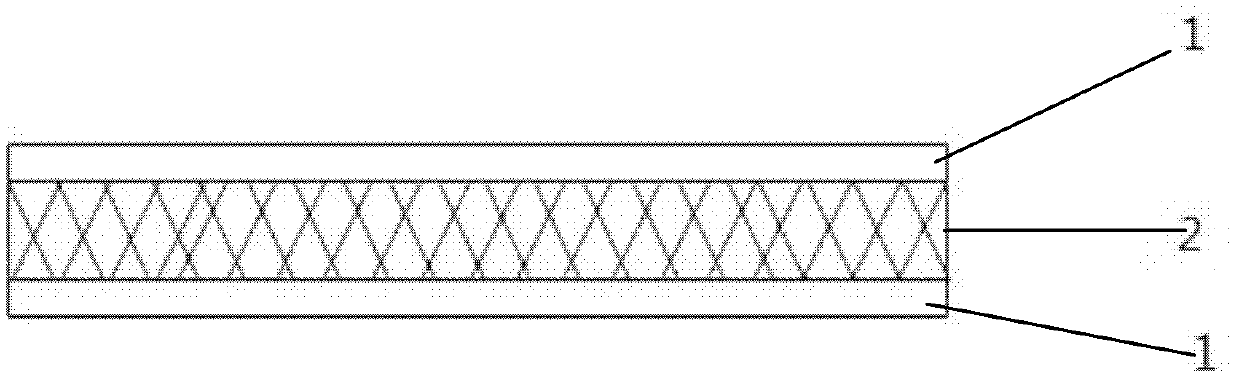

[0031] A composite material for a container floor, comprising a core layer and covering panels covering the upper and lower surfaces of the core layer, wherein the core layer is a lightweight glass mat reinforced thermoplastic composite material board composed of long glass fibers and polypropylene resin, and the weight content of the glass fibers is 55%, polypropylene is 45%, the density of the core material is 0.8g / cm 3 , the porosity is 43%.

[0032] The upper and lower covering panels are extruded sheets of short glass fiber reinforced polypropylene material, and the content of glass fiber in the covering panel material is 45%.

[0033] Its preparation method comprises the following steps:

[0034] (1) The weight per unit area of the 6 layers used as the core layer is 1600g / m 2 The glass fiber and polypropylene fiber hybrid mat is placed in the short glass fiber reinforced polypropylene composite material sheet as the covering panel with a thickness of 4mm at the top a...

Embodiment 2

[0037] A composite material for a container bottom plate, comprising a core layer and covering panels covering the upper and lower surfaces of the core layer. The core layer is a lightweight glass mat reinforced thermoplastic composite material board composed of long glass fibers and polypropylene resin. The weight content of glass fibers is 55%, polypropylene is 45%, and the density of the core material is 0.8g / cm 3 , the porosity is 43%. The upper and lower cover panels are glass mat reinforced polypropylene material or GMT. The content of glass fiber in the material is 40%.

[0038] Its preparation method comprises the following steps:

[0039] (1) The weight per unit area of the 6 layers used as the core layer is 1600g / m 2 The glass fiber and polypropylene fiber lightweight sheet (purchased from Chuzhou Jieshijie New Material Co., Ltd., GeniusLite-1600) is placed on the glass mat reinforced polypropylene composite sheet (purchased from Korea Hanwha, GMTRD40);

[004...

Embodiment 3

[0042]A composite material for a container bottom plate, comprising a core layer and covering panels covering the upper and lower surfaces of the core layer. The core layer is a lightweight glass mat reinforced thermoplastic composite material board composed of glass fiber and polypropylene resin, the weight content of glass fiber is 55%, polypropylene is 45%, and the density of the core material is 0.8g / cm 3 , the porosity is 43%. The upper and lower covering panels are continuous glass fiber reinforced polypropylene composite materials, in which the glass fiber content is 60%;

[0043] Its preparation method comprises the following steps:

[0044] (1) The weight per unit area of the 6 layers is 1600g / m 2 The glass fiber and polypropylene fiber lightweight sheet (purchased from Chuzhou Jieshijie New Material Co., Ltd., GeniusLite-1600) placed on the upper and lower continuous glass fiber reinforced polypropylene composite sheet (purchased from Liaoning Jieshi Jiexin Mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com