Preparation method of lithium iron phosphate

A lithium iron phosphate and preparation system technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of uneven distribution, poor batch stability, large particle size, etc., and achieve uniform heating and batch stability. High performance and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] In the following, the present invention will be further described with reference to the drawings and combined with the preferred embodiments, rather than limiting the present invention.

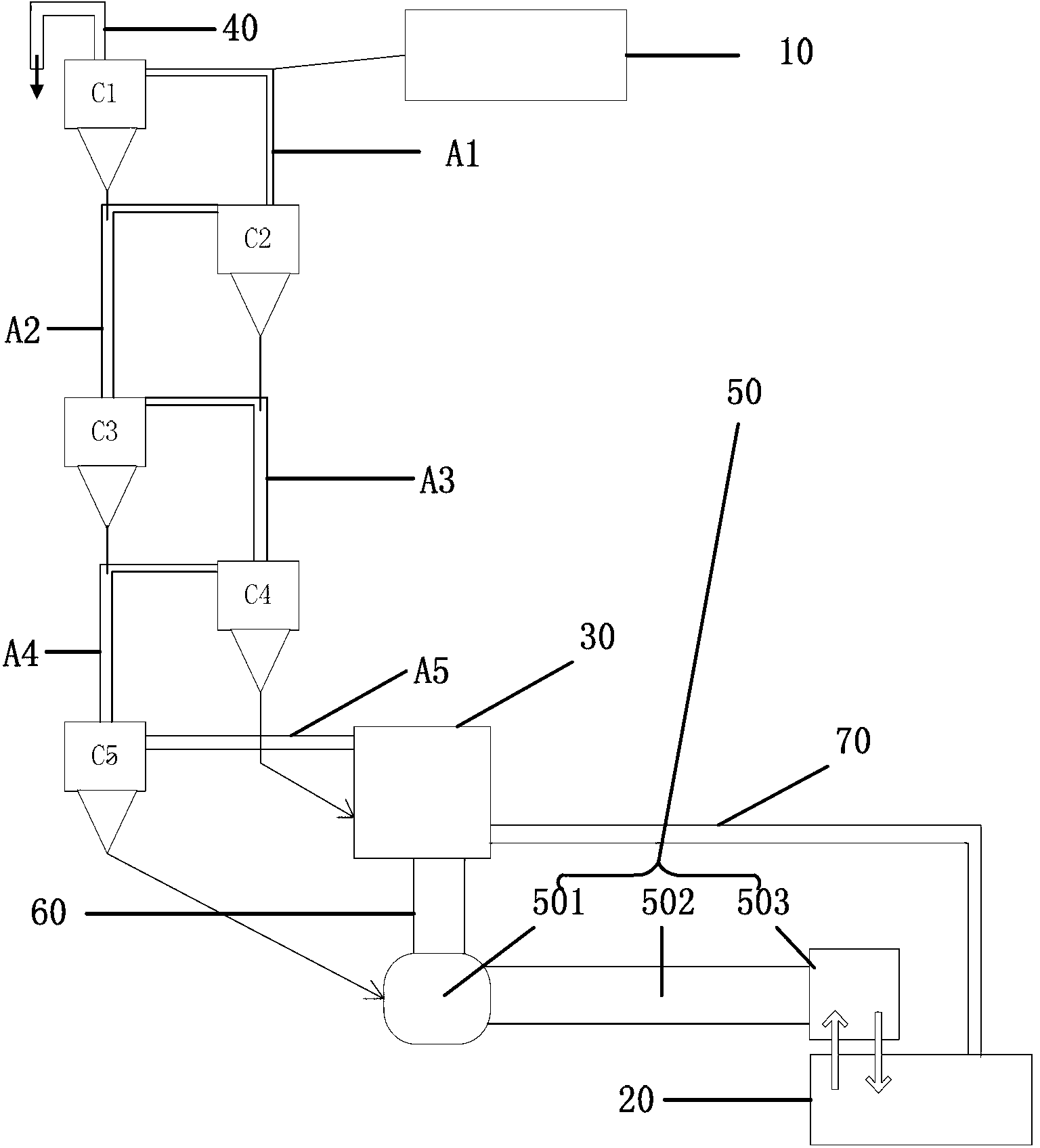

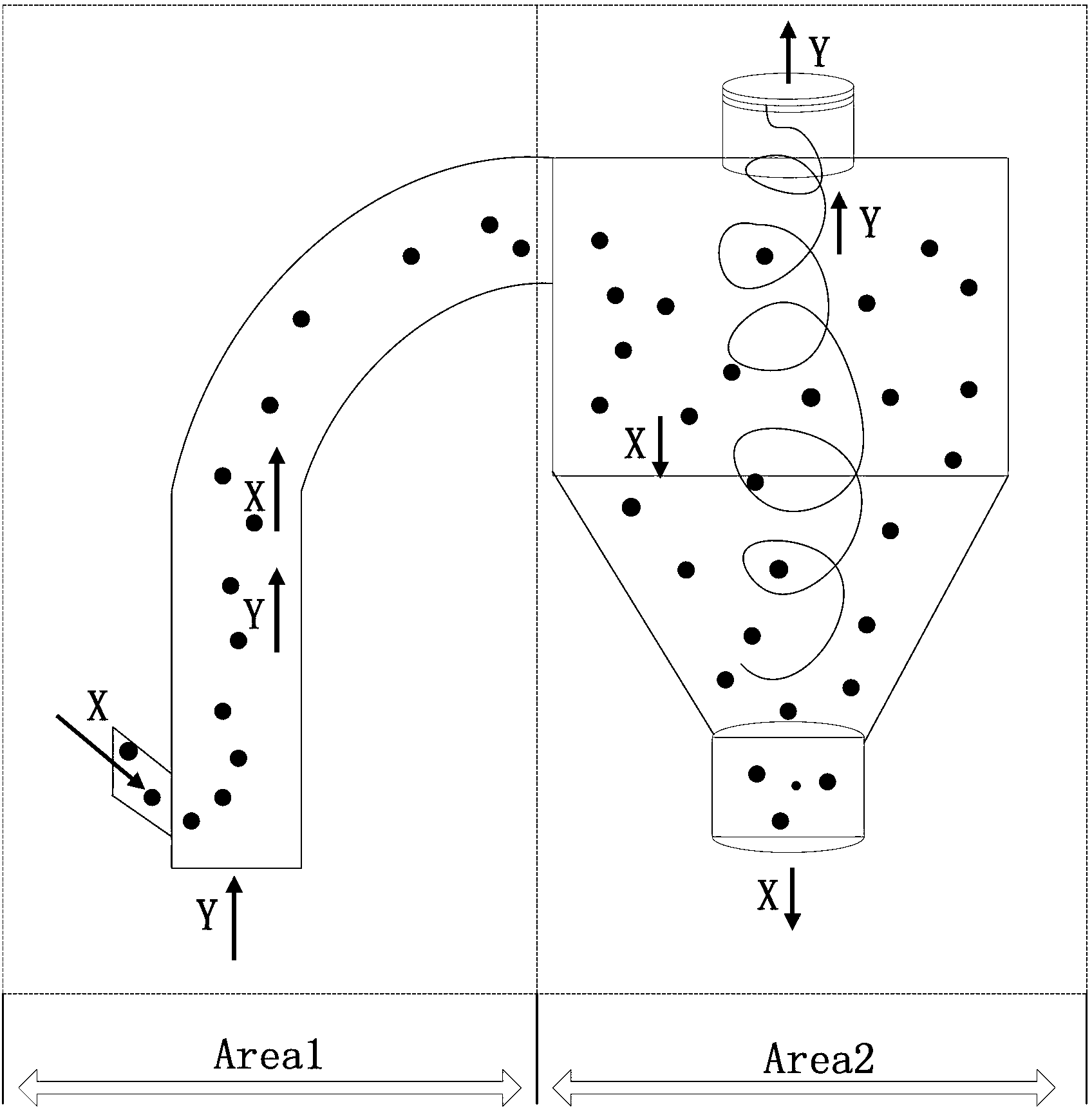

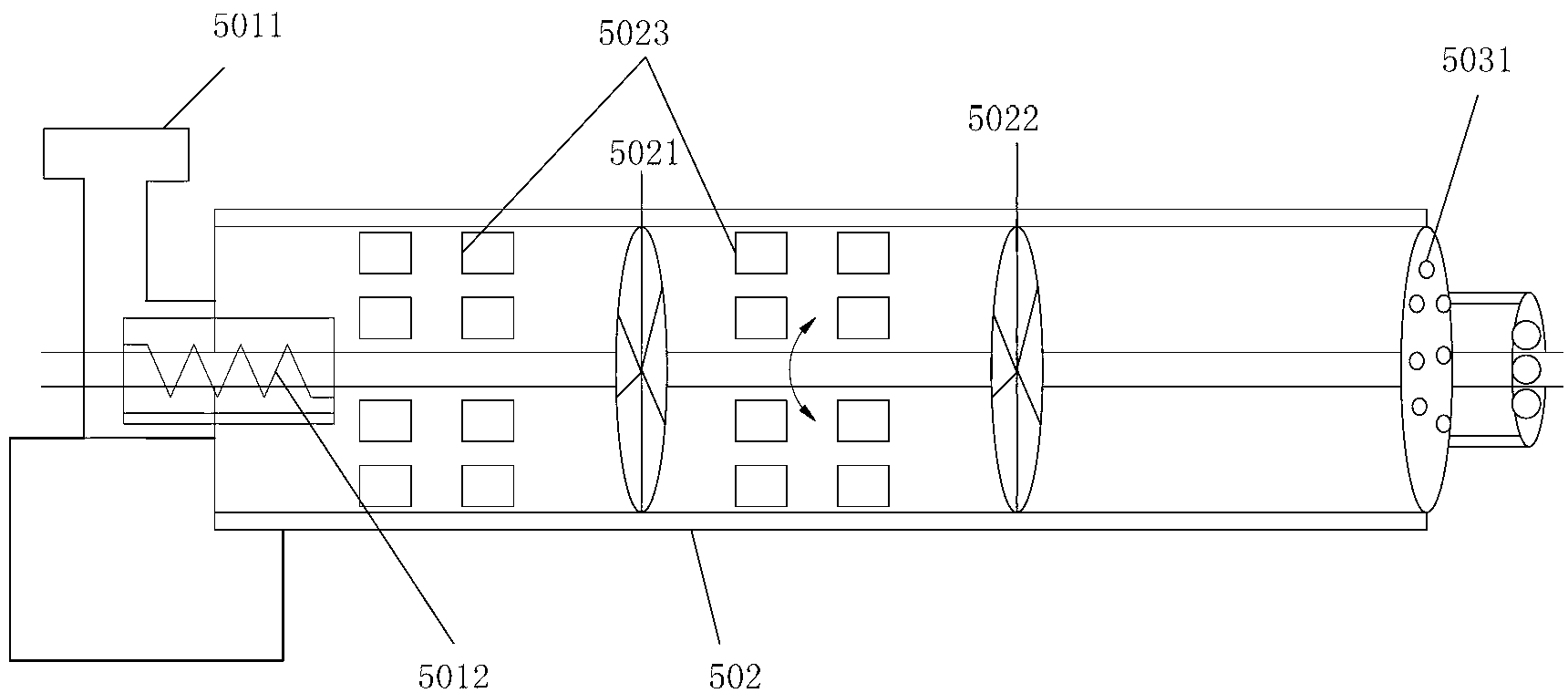

[0074] The preparation method of lithium iron phosphate in this embodiment is in a set such as figure 1 In the ball mill rotary kiln system shown, the ball mill rotary kiln system includes a ball mill 10, a cyclone preheating device, a ball mill rotary kiln, and a cooler 20, wherein the cyclone preheating device includes a five-stage heat exchange unit and a decomposition chamber For the 30 suspension heat exchange system, it should be noted that the number of heat exchange units and decomposition chambers is not limited to this. Such as figure 1 As shown, taking the ground as the reference, from top to bottom are the first stage heat exchange unit to the fifth stage heat exchange unit, each heat exchange unit includes a cyclone tube and heat exchange tube, the cyclone tube is C1, C2, C3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com