Production method of controlled-release phosphorus potassium fertilizer

A production method and slow-release technology, which are applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of slow-release phosphorus-potassium fertilizers produced by calcium dihydrogen phosphate, etc., and achieve the effects of low synthesis temperature and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

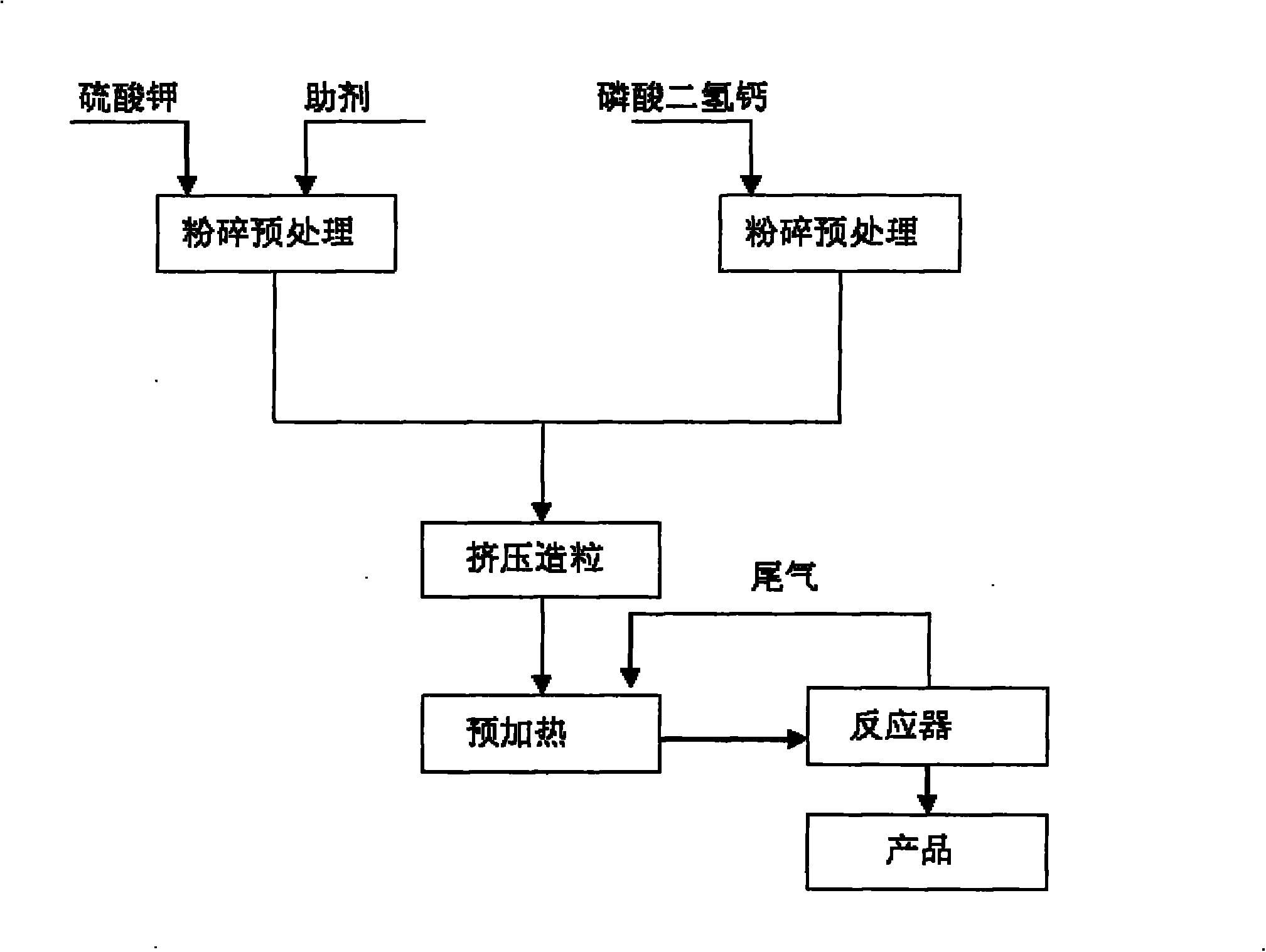

Image

Examples

Embodiment Construction

[0014] In order to make it easy to understand the technical means, creative features, work flow, and use methods of the present invention to achieve the purpose and effect, the present invention will be further described below in conjunction with examples.

[0015] Adopt technology potassium sulfate of the present invention and calcium dihydrogen phosphate to produce potassium polymetaphosphate and calcium sulfate melt slow-release fertilizer:

[0016] The first step is potassium sulfate pretreatment. Potassium sulfate is agricultural grade potassium sulfate, which needs to be pretreated. The specific process is: take 100kg of potassium sulfate (K2O content ≥ 60%), grind and pulverize, the particle size reaches 70 mesh, mix and develop independently The auxiliary agent 1kg.

[0017] The second step is to take 75kg of calcium dihydrogen phosphate for pretreatment, which needs to be ground and crushed to 70mu;

[0018] The third step is to mix potassium sulfate and calcium dihy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com