Drought-fighting and seedling-protection growth promoter for crops and preparation method for drought-fighting and seedling-protection growth promoter

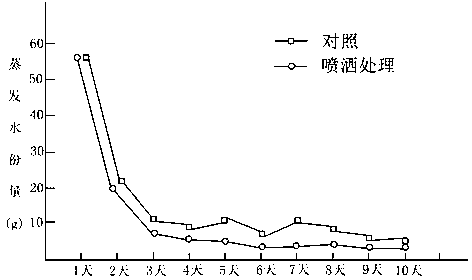

A technology for crops and growth promoters, which is applied in the field of crop drought-resistant seedling growth promoters and preparations, can solve the problems of complex production process of drought-resistant agents, unfavorable plant photosynthesis, and unstable performance, so as to avoid water evaporation loss and improve soil quality. The effect of moisture content and fast germination time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 500g of reed pulp papermaking waste liquid containing 45% liquid, and another 100g of urea-formaldehyde resin solution; start the reaction stirring device, heat up 85-90°C, add 500g of reed pulp papermaking waste liquid, that is, magnesium sulfonate salt lignin liquid, adjust Between pH 7-8, slowly add urea-formaldehyde resin solution, stir for 1 hour, then add 1 g of polyvinyl alcohol or acrylamide, continue stirring for 1 hour, and dry to obtain a yellow-brown powder. When used, it is formulated into a 1% aqueous solution and can be sprayed.

Embodiment 2

[0022] Take 500g of reed pulp papermaking waste liquid containing 45% liquid, and another 300g of urea-formaldehyde resin solution; start the reaction stirring device, heat up 85-90°C, add 500g of reed pulp papermaking waste liquid, that is, magnesium sulfonate salt lignin liquid, adjust Between pH7-8, slowly add urea-formaldehyde resin solution, stir and react for 1 hour, then add 3g of polyvinyl alcohol or acrylamide, continue to stir and react for 1 hour, and dry to obtain a yellow-brown powder. When used, it is formulated into a 1% aqueous solution and can be sprayed.

Embodiment 3

[0024] Take 250g dry base material of reed pulp papermaking waste liquid, i.e. dry base magnesium sulfonate lignin, add 500ml water to dilute, and take another 150g urea-formaldehyde resin solution; start the reaction stirring device, raise the temperature to 85-90°C, add 500g reed pulp papermaking waste The diluent of liquid-dried base material, adjust the pH between 7-8, slowly add urea-formaldehyde resin solution, stir for 1 hour, then add 1.5g of polyvinyl alcohol or acrylamide, continue stirring for 1 hour, and dry to obtain yellow brown powder. When used, it is formulated into a 1% aqueous solution and can be sprayed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com