Coal-based military fuel and preparation method thereof

A military fuel, coal-based technology, applied in the field of coal chemical industry, can solve the problems of long process, complicated operation, and difficulty in processing inferior naphthenic coking distillate oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

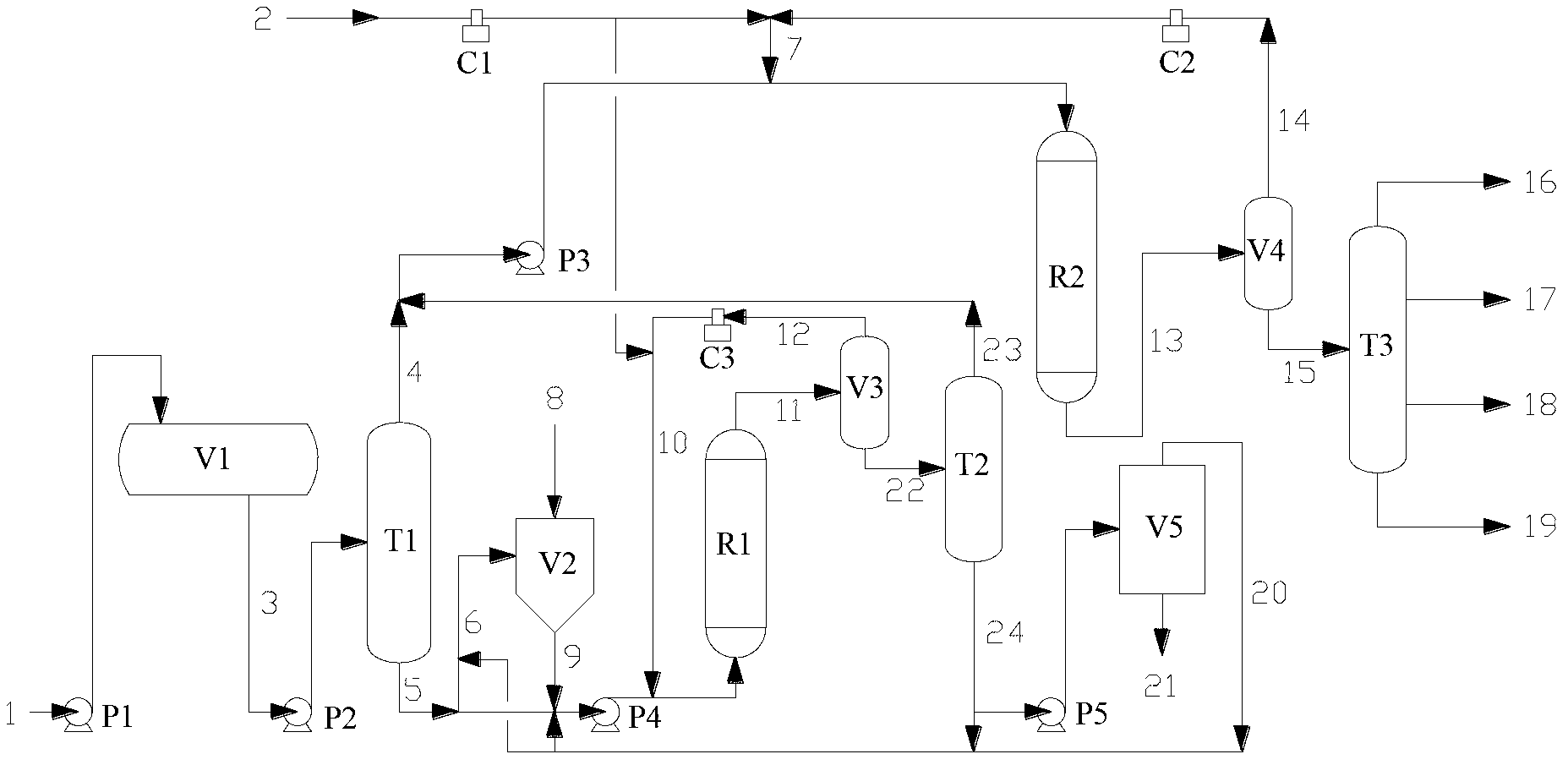

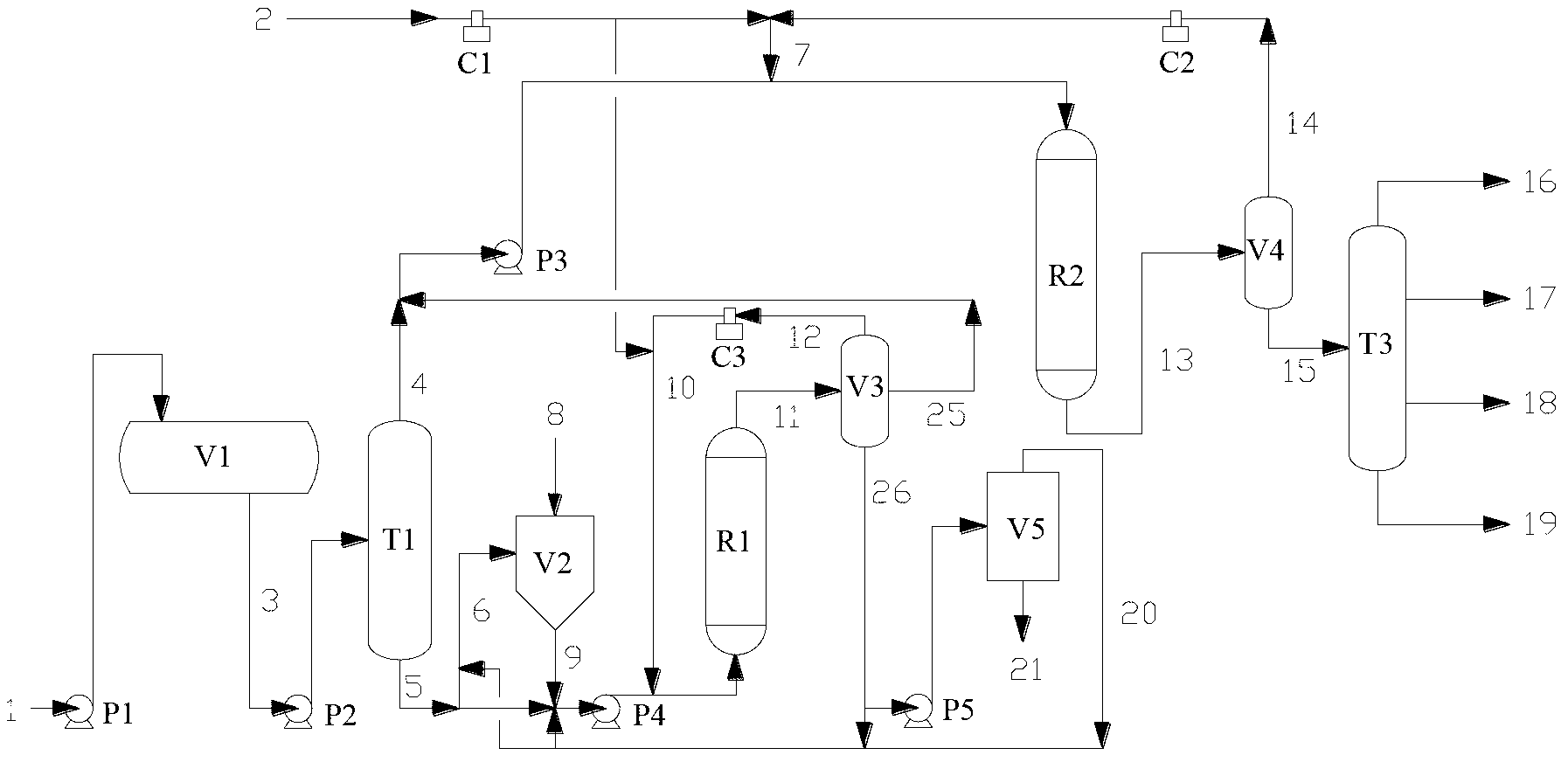

Method used

Image

Examples

Embodiment 1

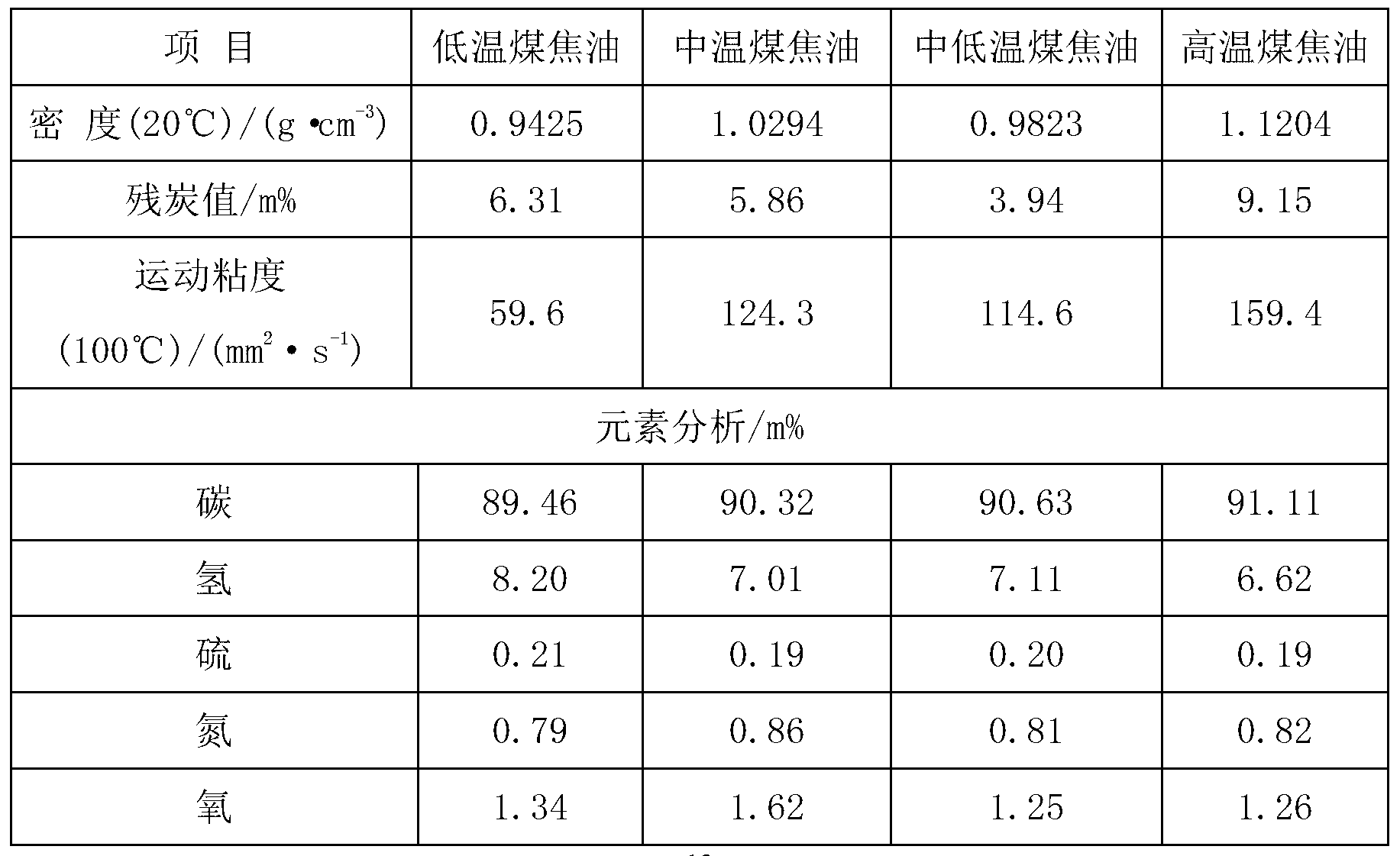

[0072] A low-temperature coal tar is used as raw material. After pretreatment, the purified coal tar is distilled and cut into light distillate oil 370°C. The heavy distillate oil >370°C is a suspended bed See Table 1 for properties of hydrocracking feedstock oil and coal tar whole distillate feedstock oil. After hydrocracking and lightening of heavy distillate oil, light oil and coal tar distillation and separation of light distillate oil can be obtained after hydrofining 3# jet fuel, battlefield general fuel, rocket kerosene and high specific gravity jet fuel, etc. Products, the main process conditions of each process unit are shown in Table 2, and the main properties of each military fuel product are shown in Table 3.

[0073] The test was carried out on a 0.2 ton / day suspended bed hydrogenation test device. The hydrocracking unit used two suspended bed reactors in series, and the deep hydrofining unit used two fixed bed reactors in series.

Embodiment 2

[0075]A medium-temperature coal tar is used as raw material. After pretreatment, the purified coal tar is distilled and cut into light distillates below 350°C and heavy distillates above 350°C. The heavy distillate above 350°C is a suspended bed See Table 1 for properties of hydrocracking feedstock oil and coal tar whole distillate feedstock oil. After hydrocracking and lightening of heavy distillate oil, light oil and coal tar distillation and separation of light distillate oil can be obtained after hydrofining 3# jet fuel, battlefield general fuel, rocket kerosene and high specific gravity jet fuel, etc. Products, the main process conditions of each process unit are shown in Table 2, and the main properties of each military fuel product are shown in Table 4.

[0076] The test was carried out on a 0.2 ton / day suspended bed hydrogenation test device. The hydrocracking unit used two suspended bed reactors in series, and the deep hydrofining unit used two fixed bed reactors in s...

Embodiment 3

[0078] A kind of medium and low temperature coal tar is used as raw material. After pretreatment, the purified coal tar is distilled and cut into light distillate oil below 370°C and heavy distillate oil above 370°C. The heavy distillate oil above 370°C is Table 1 shows the properties of the raw material oil of the raw material for suspension bed hydrocracking, and the properties of the whole distillate raw oil of coal tar. The light oil fraction after hydrocracking of heavy distillate oil and the light oil fraction separated by coal tar distillation can be hydrotreated together to obtain 3# jet fuel, common battlefield fuel, rocket kerosene and high specific gravity jet fuel and other products , the main process conditions of each process unit are shown in Table 2, and the main properties of each military fuel product are shown in Table 5.

[0079] The test was carried out on a 0.2 ton / day suspended bed hydrogenation test device. The hydrocracking unit used two suspended bed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com